3 Piping work and

refrigerant charge

101

3

SMGB0077 rev.0 - 01/2013

3.4.8 Refrigerant pipe insulation

The refrigerant circulates through the pipes at a very low temperature (several degrees below zero, depending on the

time of year and the installation). The difference in temperature with the ambient air is extremely large and causes two

signicant phenomena to be taken into account:

• Cold irradiation along the entire pipe.

• Condensation of the humidity in the surrounding air.

Actually, cold irradiation is the temperature gain experienced by the gas, as when it circulates under pressure and at such

low temperatures along the inside of the pipes, it is actually liquid and obtains the outdoor temperature (boiling at a very

low temperature) to turn into gas.

As a result of the temperature gain (although it is actually perceived as cold emission), the loses its capacity to cool and

the system does not perform as expected. Furthermore, the humidity in the surrounding air condenses on the pipe and the

greater the temperature difference and the longer the pipe, the more water is produced.

In view of this, the refrigerant pipes must be tted with a suitable insulation system that prevents the increase in temperature

of the refrigerant and the subsequent loss of energy and the condensation of water along the entire pipe.

Refrigerant pipes must always be separately insulated, using closed cell insulation foam designed especially for refrigeration.

This insulation foam, supplied by the installer, can be obtained in different formats. The most common is in the form of

sheets and rolls of tubes of different diameters.

Furthermore, all connections between the different sections of insulation tubes must be reinforced with adhesive tape of

the same characteristics.

Once all of the unit installation and adjustment work is complete, all threaded joints and valves must also be covered with

adhesive tape.

3.4.9 Refrigerant pipe suspension

Only suspend the refrigerant pipes at specic points of the building.

Whenever possible, avoid suspending them from parts subject to

structural movement, e.g. places close to expansion joints or outer

walls, etc.

Prevent the refrigerant pipes from touching weak parts of the

building, such as walls (non-structural), partition walls, ceilings,

etc. Otherwise, operating noise may be caused by pipe vibrations

(pay special attention in the case of short pipes).

A: points where the refrigerant pipes pass through the different

structural parts of the building.

B: indoor unit.

A

B

1-15 mm

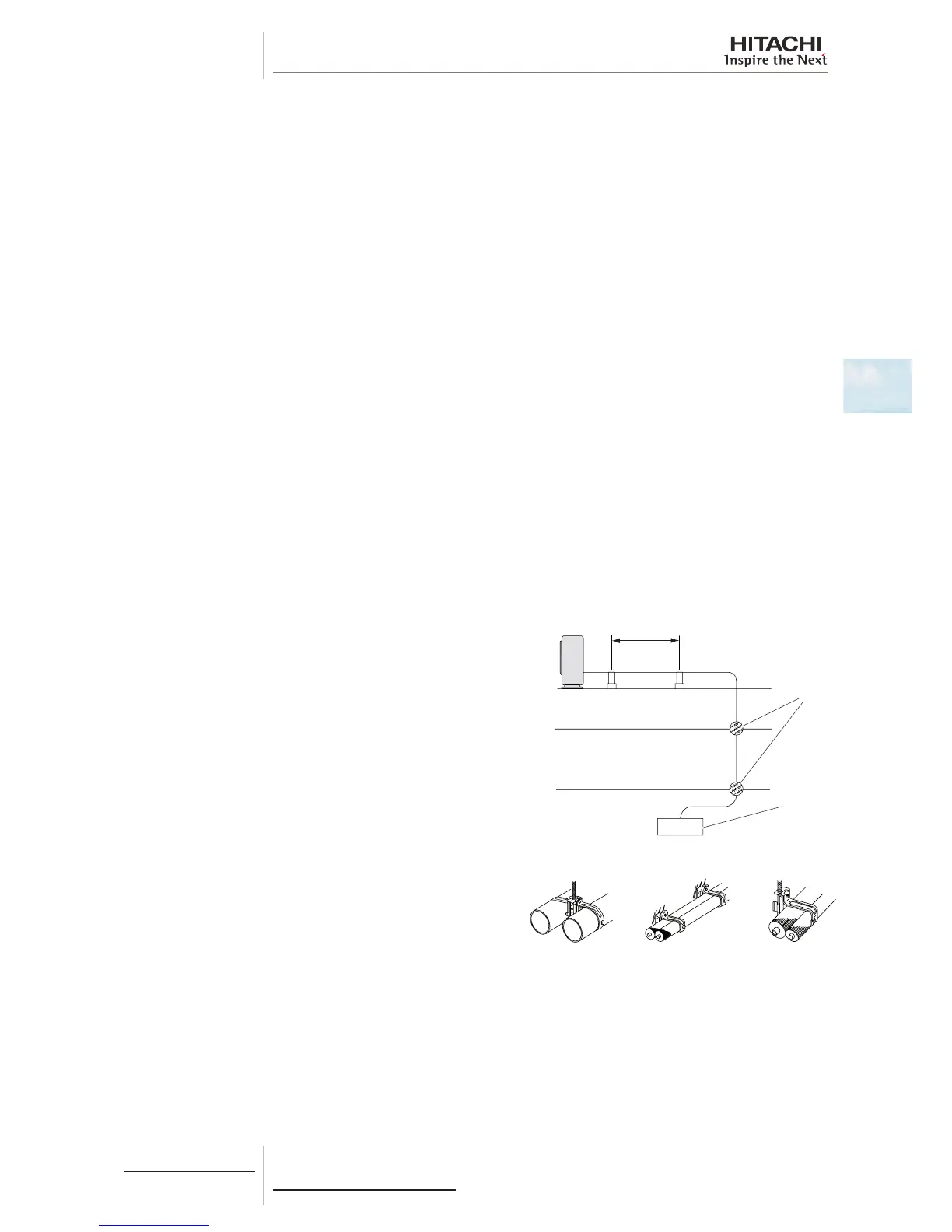

Use suitable suspension systems for refrigeration pipes or clamps

to suspend the pipes, as shown in the diagram.

Loading...

Loading...