15

PMEN0654 rev.0 - 12/2023

5

FLARED PIPES

REFRIGERANT PIPING AND REFRIGERANT CHARGE

Therefore, all work carried out on the copper pipes for refrigerant must follow the three principles

described below:

Principle Cause of the fault Possible fault Prevenve measure

Absence of

humidity

Water inltraon due to

insucient protecon on the

ends of the pipes.

Condensaon on the inside of

the pipes.

Insucient vacuum.

Ice on the inside of the pipe,

on the expansion valve (water

obstrucon)

+

Absorpon of oil humidity and

oxidaon

↓

Filter clogging, insulaon and

compressor fault

Seal the ends of the pipes.

Protect and insulate the ends of

the pipes.

↓

Wash

↓

Vacuum dry (*)

Cleaning

Dust or other elements

entering the ends of the pipes.

Film of rust formed during

brazing without nitrogen

injecon.

Insucient nitrogen wash aer

brazing.

Expansion valve, Capillary tube

and lter clogging, Oil oxidaon

↓

Compressor fault, insucient

cooling or heang

Fit caps to the ends of the pipes.

Protect and insulate the ends of

the pipes.

↓

Wash

Absence of

leaks

Brazing fault.

Flaring fault and insucient

torque.

Insucient torque on

compressor connectors.

Lack of refrigerant, Drop in

performance, Compressor fault,

Oil oxidaon

↓

Compressor overheang

Carry out basic brazing →

Flaring → Connecon work

carefully

↓

Airght test

↓

Preserving of vacuum

(*) One gram of water becomes approximately 1000 l of steam at 1 Torr. (1 Torr = 1 mmHg = 133.32 Pa). Therefore, a

long me must be spent on vacuum work using a small pump.

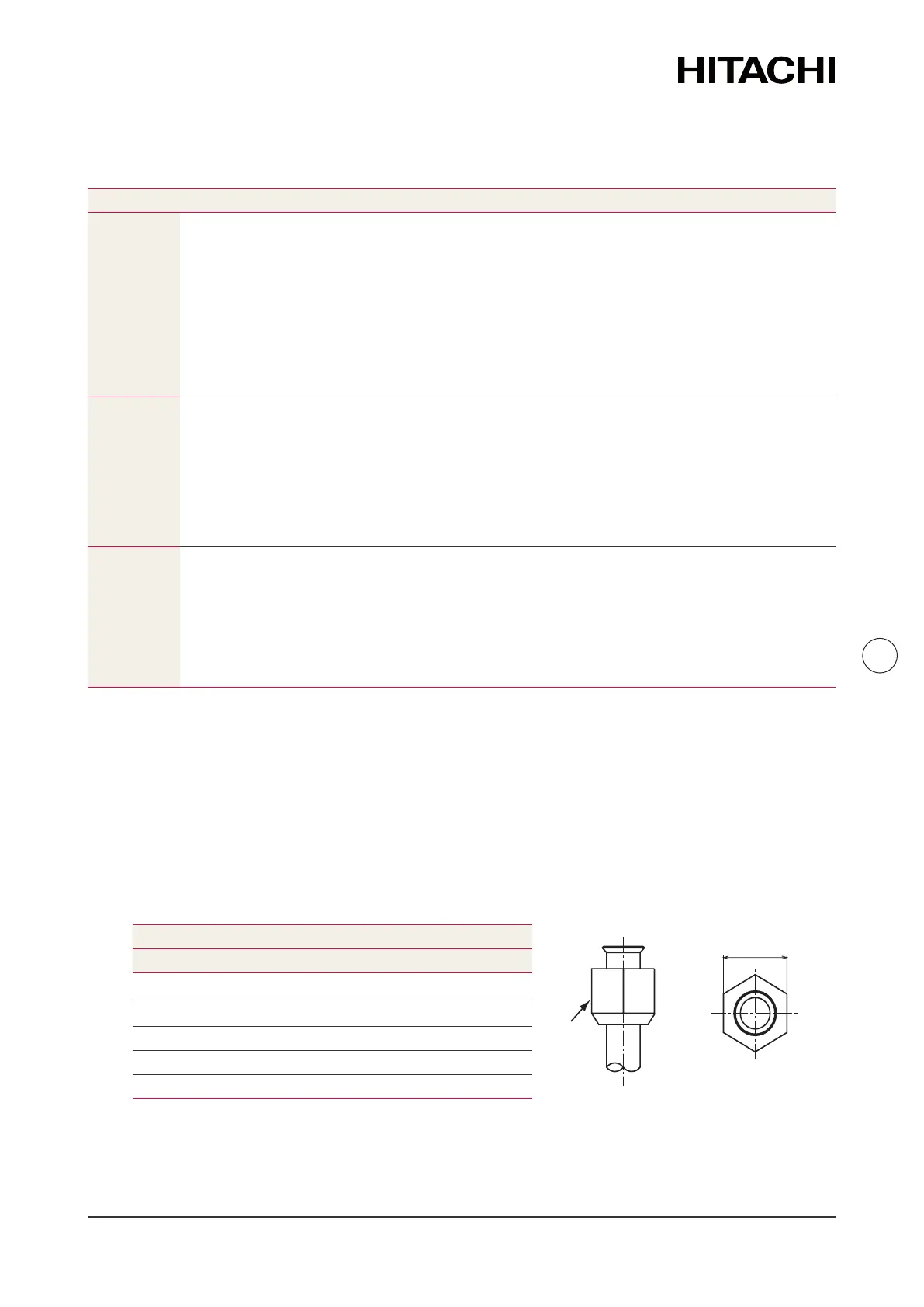

5.3 Flared pipes

5.3.1 Selecon of the connecon with are ng

If it is not possible to perform the widening operaon, use a connecon with are ng.

Distance between sides -B- of the nut -A-

Diameters (mm) -B- (mm)

Ø6.35 17

Ø9.52 22

Ø12.7 26

Ø19.05 36

Check that there are no scratches, adhered grinding swarf, deformaon or surface unevenness at

the aring part.

Loading...

Loading...