22

PMEN0654 rev.0 - 12/2023

5

SUSPENSIONOFREFRIGERANTPIPING

REFRIGERANT PIPING AND REFRIGERANT CHARGE

NOTE

• Do not use insulaon material that contains NH

3

because it can damage cooper pipe material

and can be a source of future leakage.

• Where polyethylene foam insulaon is used, a 10 mm thick layer should be used for the liquid

pipe and between 15 and 20 mm for the gas pipe.

• Insulate the liquid piping completely to avoid a decrease of performance; if not, it will cause

sweang on the surface of the pipe.

• Install the insulaon aer the pipe surface temperature has dropped to the same temperature

as that of the room, otherwise the insulaon may melt.

• Where the er has supplied his own branches, these should be appropriately insulated to avoid

decreases in capacity in line with to environmental condions and dew on the surface of the

piping due to low pressure.

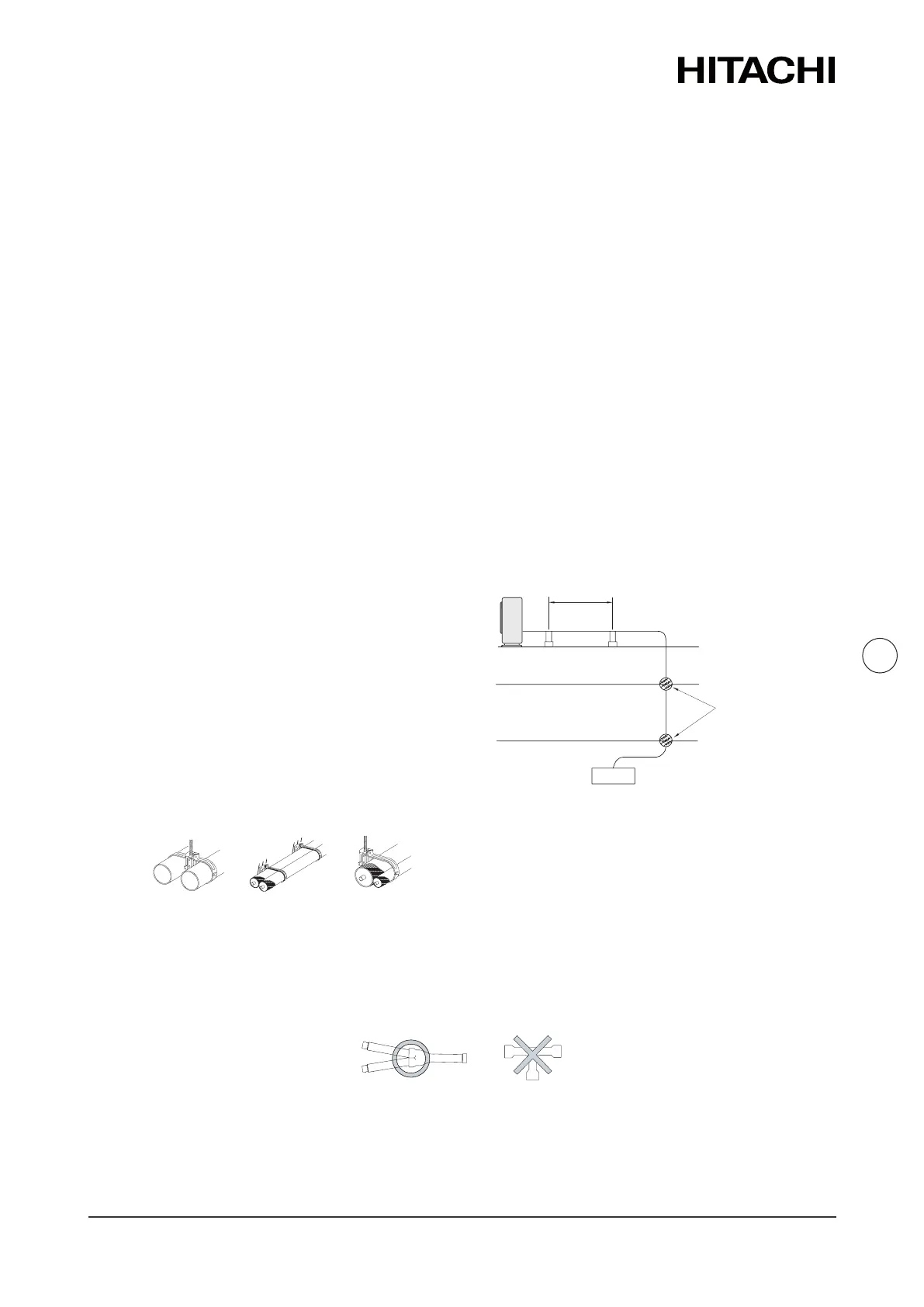

5.6 Suspension of Refrigerant Piping

Suspend the refrigerant piping at certain points and

prevent the refrigerant piping from touching the

weak part of the building such as wall, ceiling, etc…

(If touched, abnormal sound may occur due to the

vibraon of the piping. Pay special aenon in case

of short piping length).

Do not x the refrigerant piping directly with the

metal ngs. (The refrigerant piping may expand

and contract).

Some examples for suspension method are shown

below.

For suspending

heavies

For piping along

the wall

For instant

installaon work

1 ~ 15m

Indoor unit

Points where the

refrigerant pipes

pass through the

dierent structural

parts of the building.

(Fire-Proof secon

treatment)

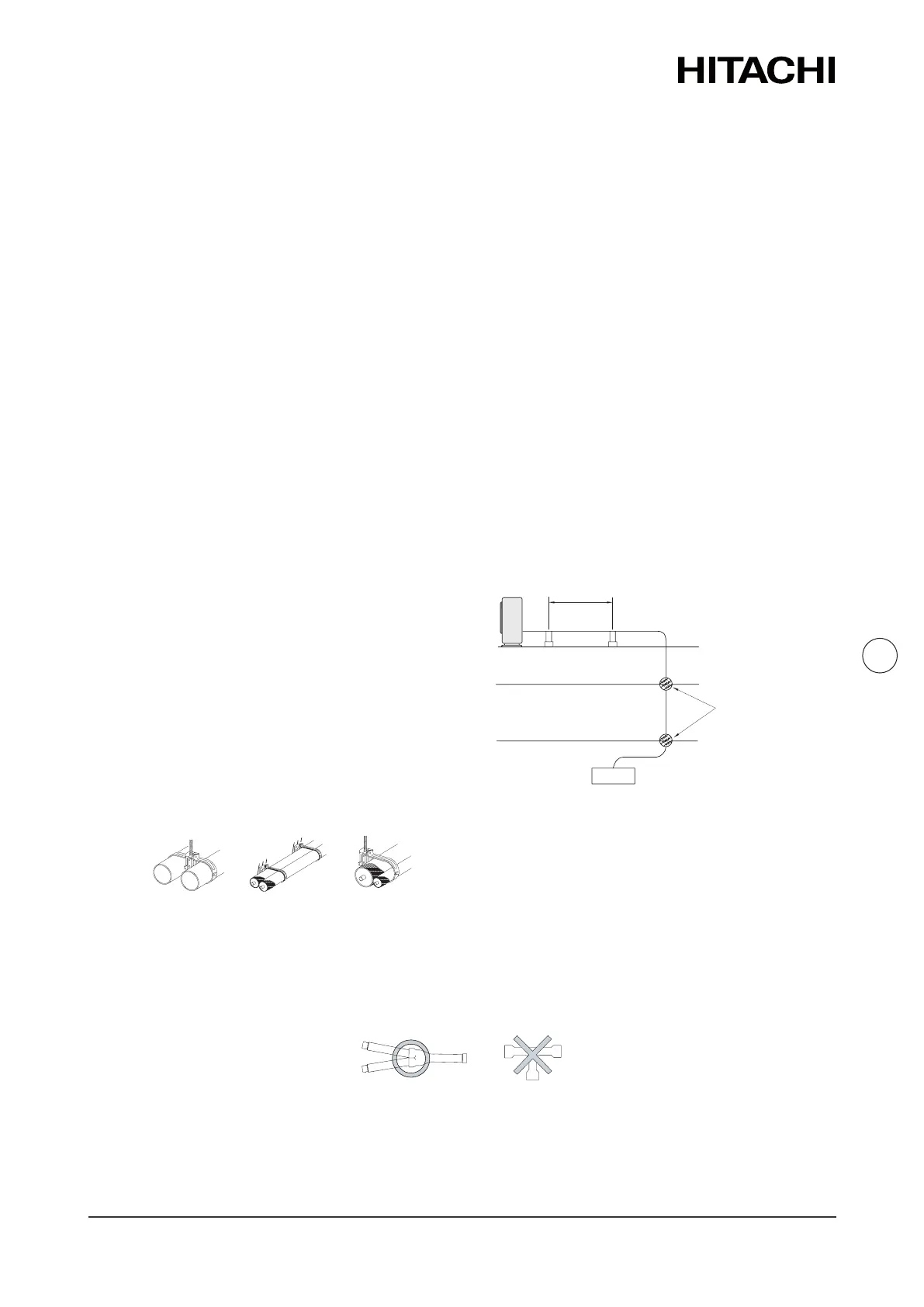

5.7 Line branch and header branch installaon

Install the distributor supplied by Hitachi on request.

A tee can not be installed instead of a branch pipe.

Fix the branch pipe horizontally to the pillar, wall or ceiling. Piping must not be xed rigidly to the

wall as thermal expansion and contracon can cause pipe fracture.

Loading...

Loading...