21

PMEN0654 rev.0 - 12/2023

5

REFRIGERANTPIPEINSULATION

REFRIGERANT PIPING AND REFRIGERANT CHARGE

CAUTION

• Do not braze on refrigerant pipes without a dry nitrogen gas injecon system. Otherwise, a layer

of rust will form that may become detached when the refrigeraon system is started, causing

lter or compressor blockages.

• NEVER USE oxygen, acetylene or uorocarbonated gas to replace nitrogen gas: this will cause an

explosion or will generate toxic gas.

Keep the nitrogen gas pressure within the indicated values. A rise in the pipe could cause an

explosion.

5.5 Refrigerant pipe insulaon

The refrigerant pipes must be ed with a suitable insulaon system that prevents the increase in

temperature of the refrigerant and the subsequent loss of energy and the condensaon of water

along the enre pipe.

Refrigerant pipes must always be separately insulated, using closed cell insulaon foam designed

especially for refrigeraon. This insulaon foam, supplied by the installer, can be obtained in

dierent formats. The most common is in the form of sheets and rolls of tubes of dierent

diameters.

Furthermore, all connecons between the dierent secons of insulaon tubes must be reinforced

with adhesive tape of the same characteriscs.

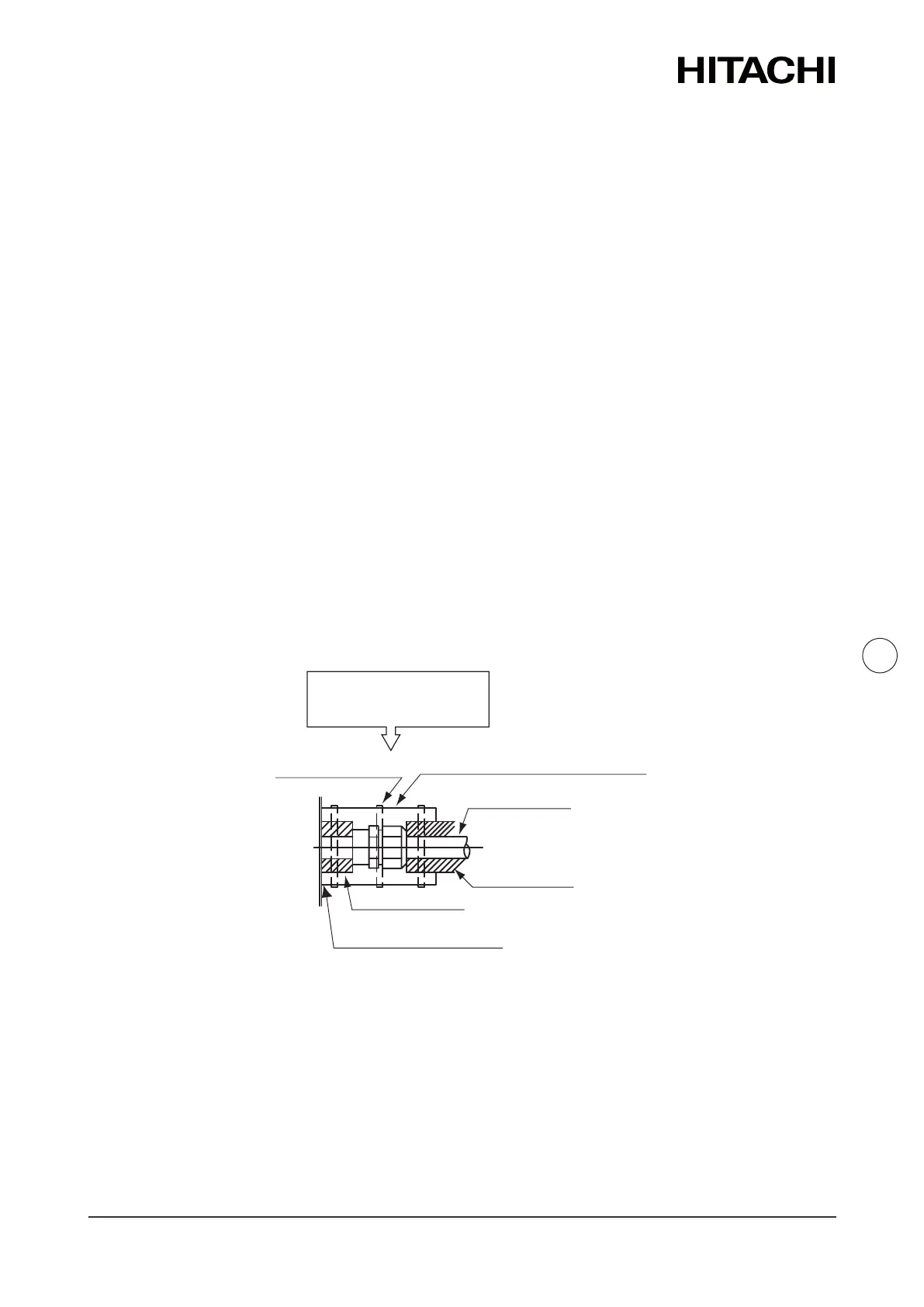

Fasten securely cord clamps and

the vinyl tape in order to prevent

the pipe from dew condensaon

Fix the vinyl tape posion at the vercal part

(Insulaon for refrigerant pipe (eld-supplied))

Refrigerant pipe

(eld-supplied)

Fasten 3 places of the

pipe by cord clamps

(eld-supplied)

Insulaon for refrigerant pipe

(eld-supplied)

Insulaon material

(factory-supplied)

Check no clearance between the indoor

unit and the insulaon

Unit side

! CAUTION

• On compleng the installaon of the refrigerant pipes, insulate the unions and are-nuts at

the piping connecon part completely, insulate them appropriately using suitable insulang

material and seal the open space between the holes made and the pipe.

• For units with air panel: If coang the oponal air panel with a forming agent (recommended

Gupoex) aer installaon, make sure that the forming agent does not contact it. Otherwise, it

could cause a breakage of the panel, resulng in the panel falling. If the forming agent contacts

the air panel, completely wipe it o.

Loading...

Loading...