16

PMEN0654 rev.0 - 12/2023

5

FLARED PIPES

REFRIGERANT PIPING AND REFRIGERANT CHARGE

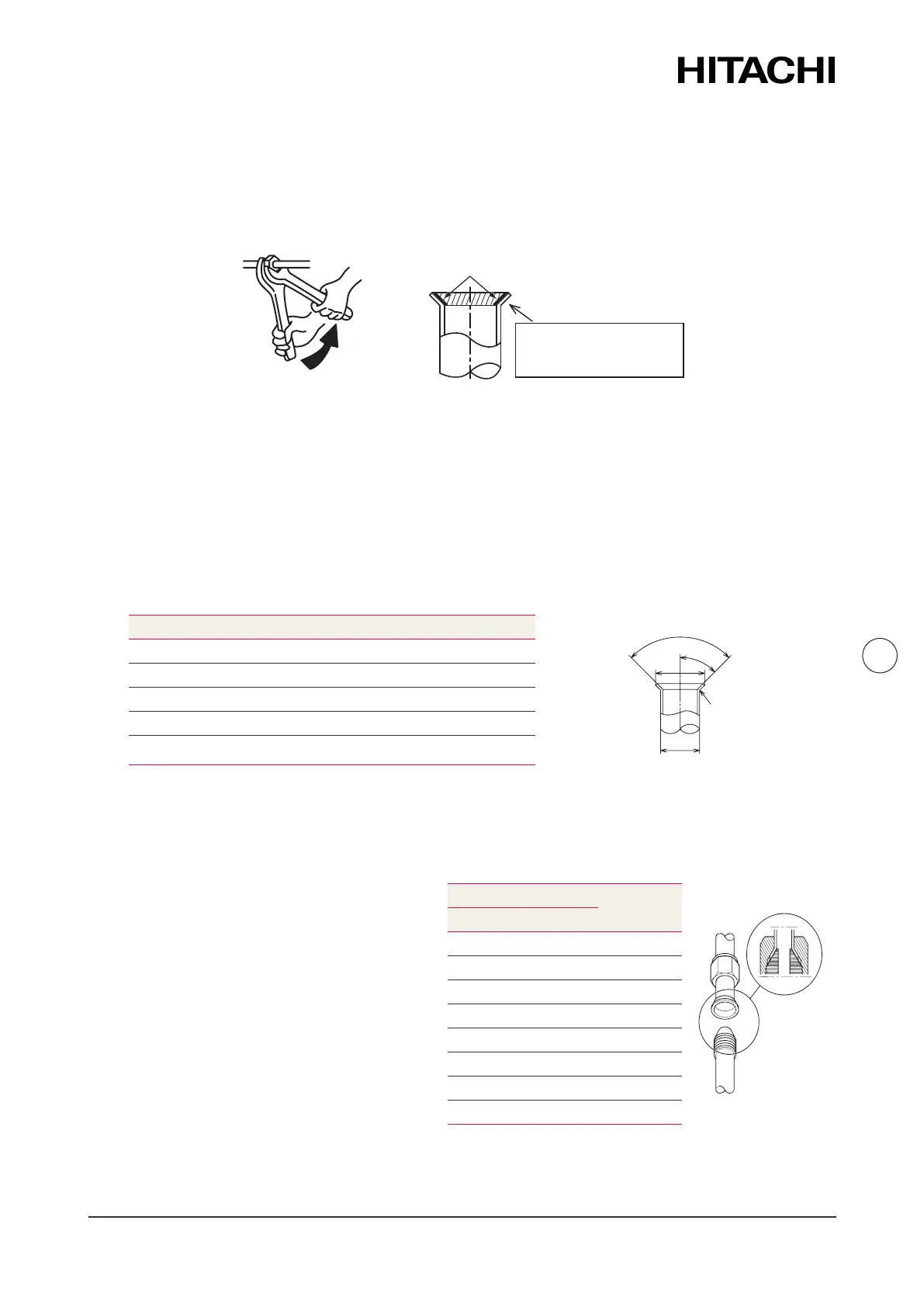

Before ghtening the are nut, apply the refrigerant oil (eld-supplied) of the same type and brand

that the compressor installed in the outdoor unit is using in thin layer over the aring part. Do not

apply the oil on other porons. Tighten the are nut for the liquid pipe to the specied torque with

two spanners. Then, ghten the are nut for the gas pipe in the same way. Aer ghtening work,

check that there is no refrigerant leakage.

Do not apply the refrigerant

oil to the outside of the

aring part.

Apply refrigerant oil

! CAUTION

For units with air panel be careful that the refrigerant oil does not contact the air panel because it

may cause a crack.

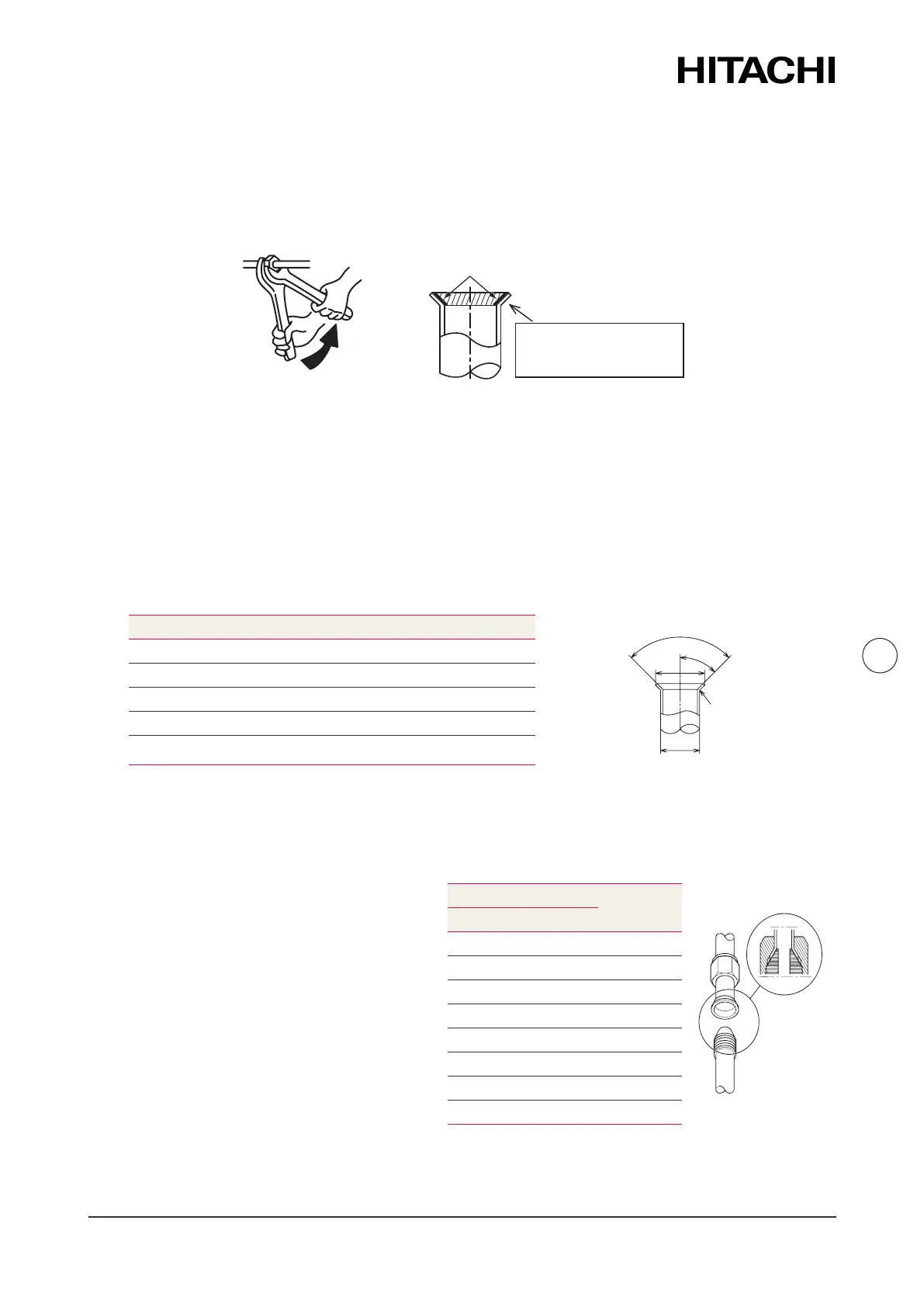

5.3.2 Dimensions of ared pipe

Perform the widening operaons in accordance with the measurements shown below.

Diameters (mm)

A

+0

-0.4

(mm)

Ø6.35 9.1

Ø9.52 13.2

Ø12.7 16.6

Ø15.88 19.7

Ø19.05 –

(1)

0.4-0.8R

45º ± 2º

øA

ø

d

90º±2

(1)

Not possible to perform the widening using pipe. In this case, use a connection with are tting.

5.3.3 Flared connecon mounng

Apply a thin layer of oil to the cone opening

for refrigeraon systems. Line up the end of

the ared pipe to face the ng to which it is

to be threaded.

Gently rest the female cone on the male cone

and check that the measurement is correct.

Keep the connecon lined up with one hand

and gently thread on the are nut with the

other.

Tighten the connecon to the corresponding

ghtening torque indicated in the table.

Nominal diameter

Tightening

torque

Ø6.35 1/4 20 N·m

Ø12.7 1/2 60 N·m

Ø19.05 3/4 100 N·m

Ø25.4 1 –

Loading...

Loading...