OM-947 Page 18

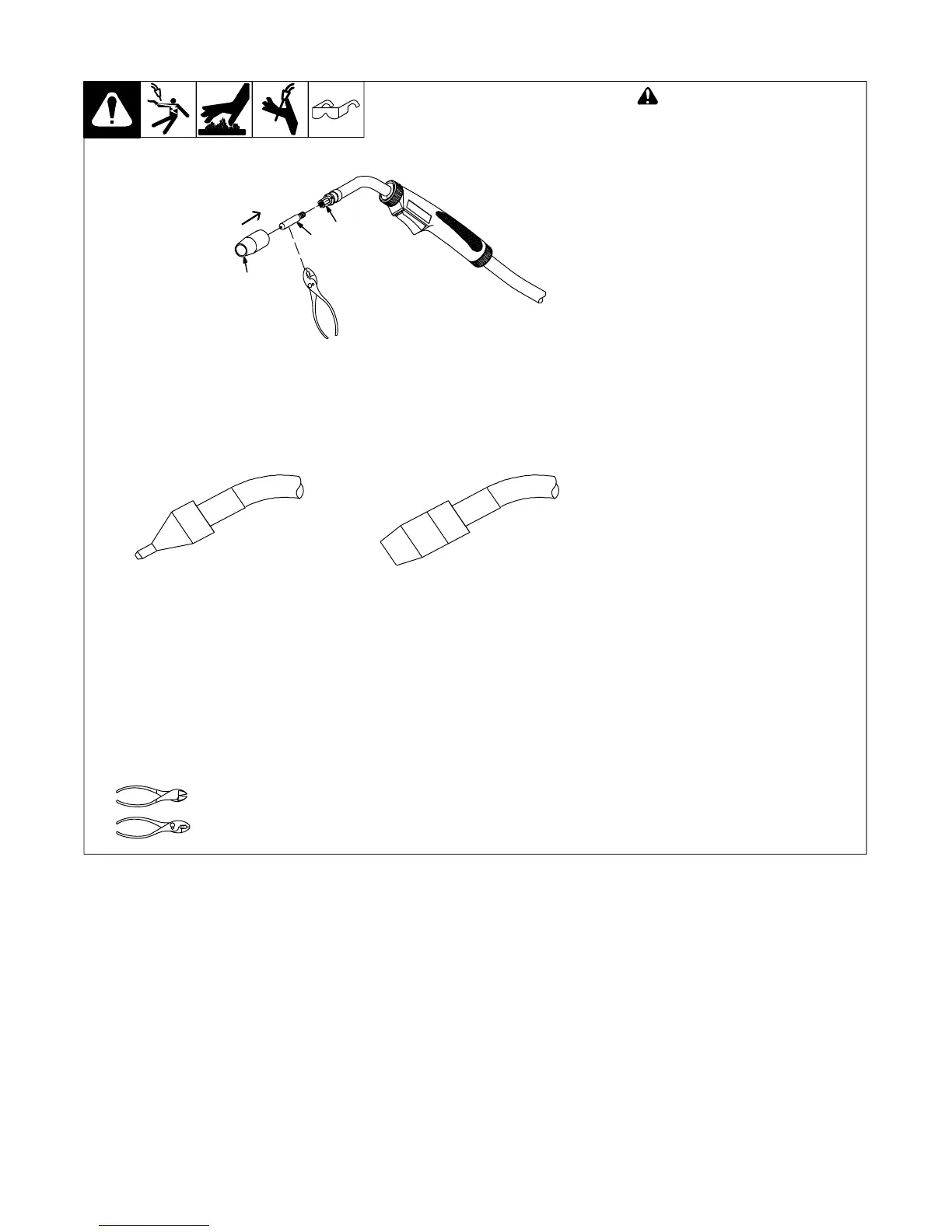

5-8. Installing Contact Tip And Nozzle

Tools Needed:

Ref. 804 241-A

! Turn off welding power source.

1 Nozzle

Remove nozzle.

2 Contact Tip

3 Tip Adapter

Thread welding wire through gun (see

Section 5-9).

Slide contact tip over wire and tighten

tip into tip adapter.

Install nozzle.

1

2

3

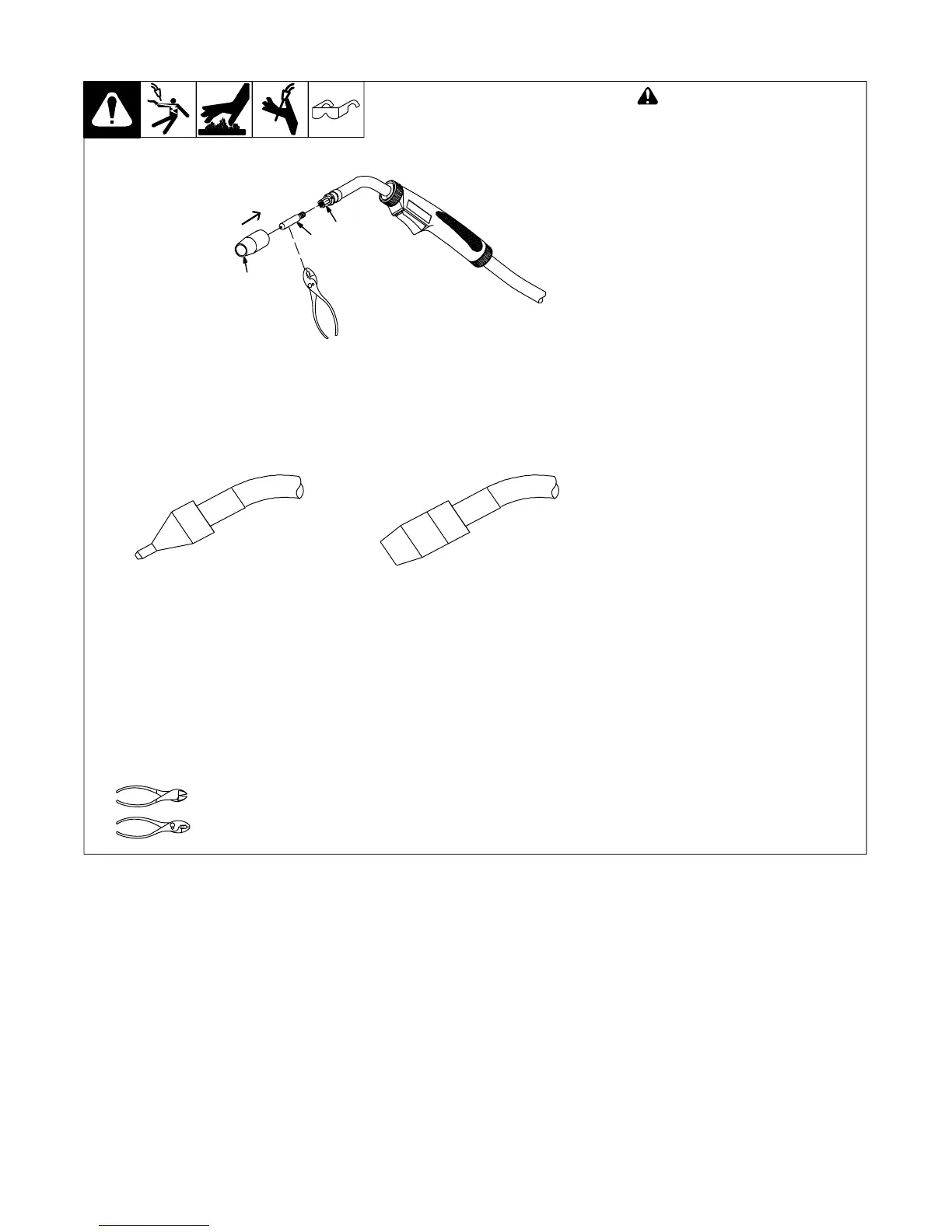

Flux Nozzle MIG Nozzle

Use with flux cored wire only.

Narrow design allows access in

tight spaces and provides better

visibility of puddle during welding.

Use with solid or flux cored wire.

Push nozzle over contact tip and

adapter until it is seated onto

adapter. Contact tip will be

exposed approximately 7/16 in.

(11.3 mm) when installed properly.

Push nozzle over contact tip and

adapter until it is seated onto

adapter. End of contact tip will be

flush with end of nozzle when

installed properly.

Loading...

Loading...