OM-947 Page 32

SECTION 9 − WIRE WELDING GUIDELINES

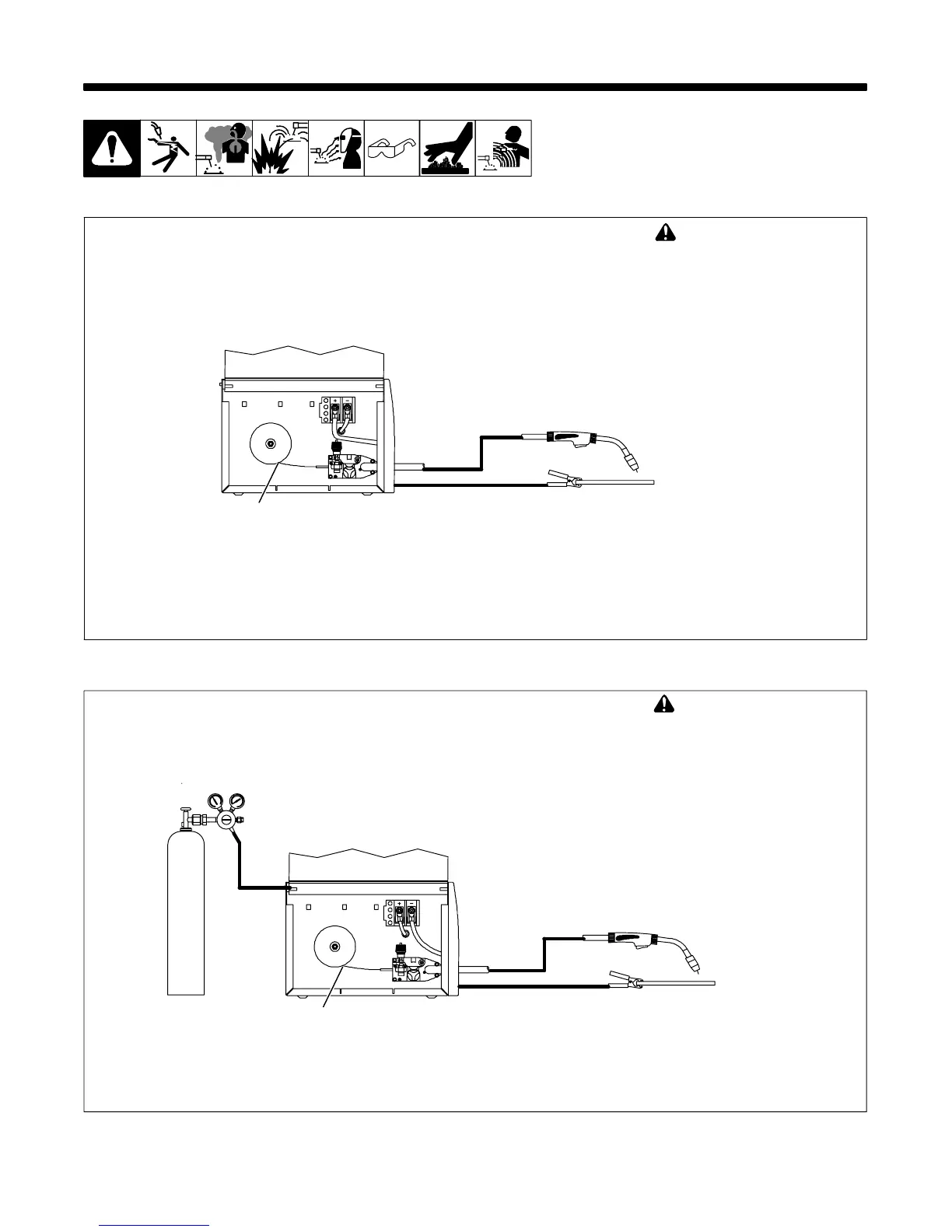

9-1. Typical FCAW Process Connections

! Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

Wire Feeder/

Power Source

fcaw 1/2003 / Ref. 803 444-A

Self-Shielding Flux

Core Wire

Workpiece

Gun

Work Clamp

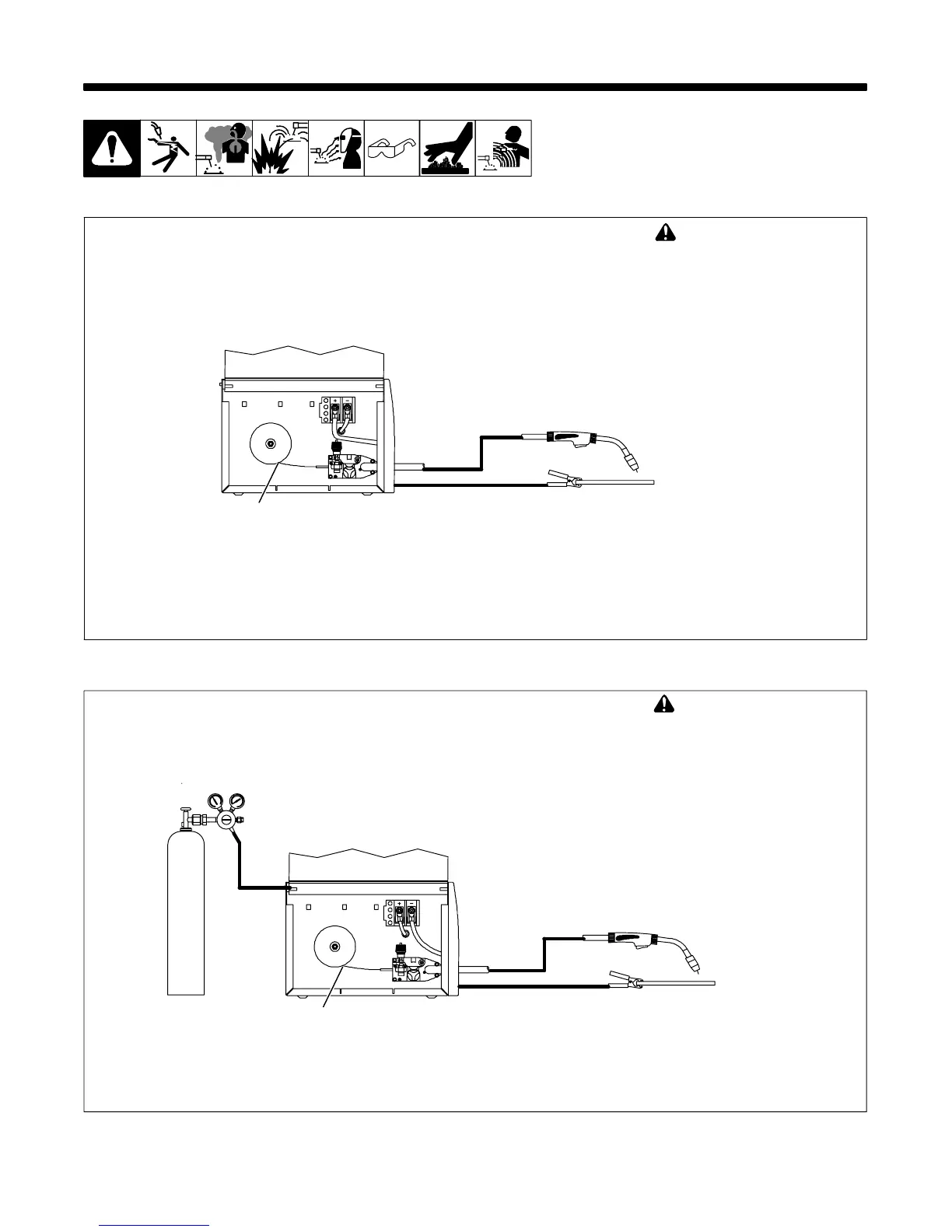

9-2. Typical MIG Process Connections

! Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

Wire Feeder/

Power Source

Regulator/

Flowmeter

Gas Hose

Shielding

Gas

light mig 5/967 / Ref. 803 444-A

Solid Wire

Workpiece

Gun

Work Clamp

Loading...

Loading...