OM-944 Page 22

SECTION 5 – MAINTENANCE &TROUBLESHOOTING

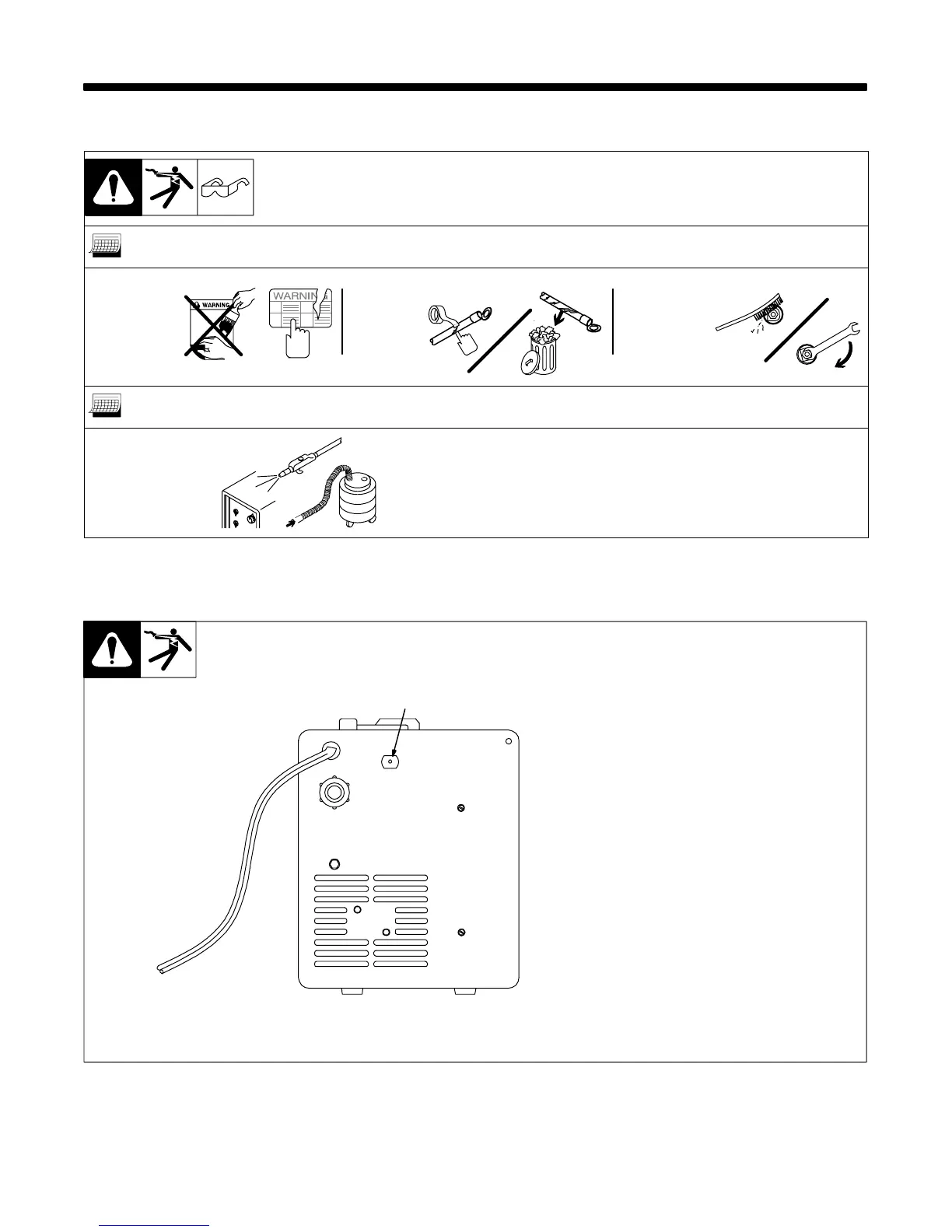

5-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months

Replace

unreadable

labels.

Repair or

replace

cracked

weld cable.

Clean and

tighten weld

terminals.

6 Months

Blow out or

vacuum inside.

During heavy

service, clean

monthly.

Or

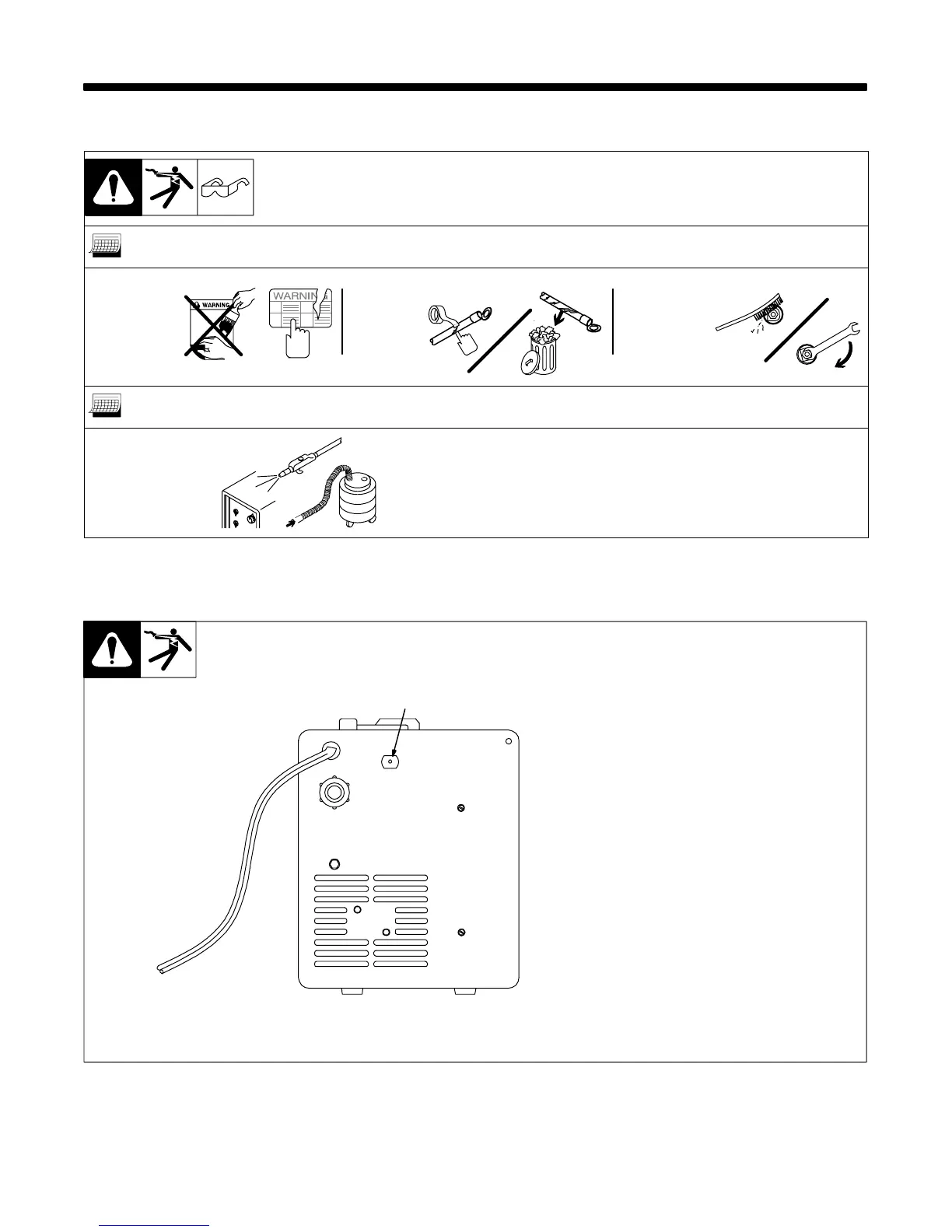

5-2. Overload Protection

802 441

1 Circuit Breaker CB1

CB1 protects unit from overload. If

CB1 opens, unit shuts down.

Reset breaker.

1

5-3. Drive Motor Protection

Drive motor protection circuit protects drive motor from overload. If drive motor becomes inoperative, release gun

trigger and wait until protection circuit resets allowing drive motor to feed wire again.

Loading...

Loading...