CHAPTER 12: DESCRIPTION OF PARAMETER SETTINGS

179 63-4528—04

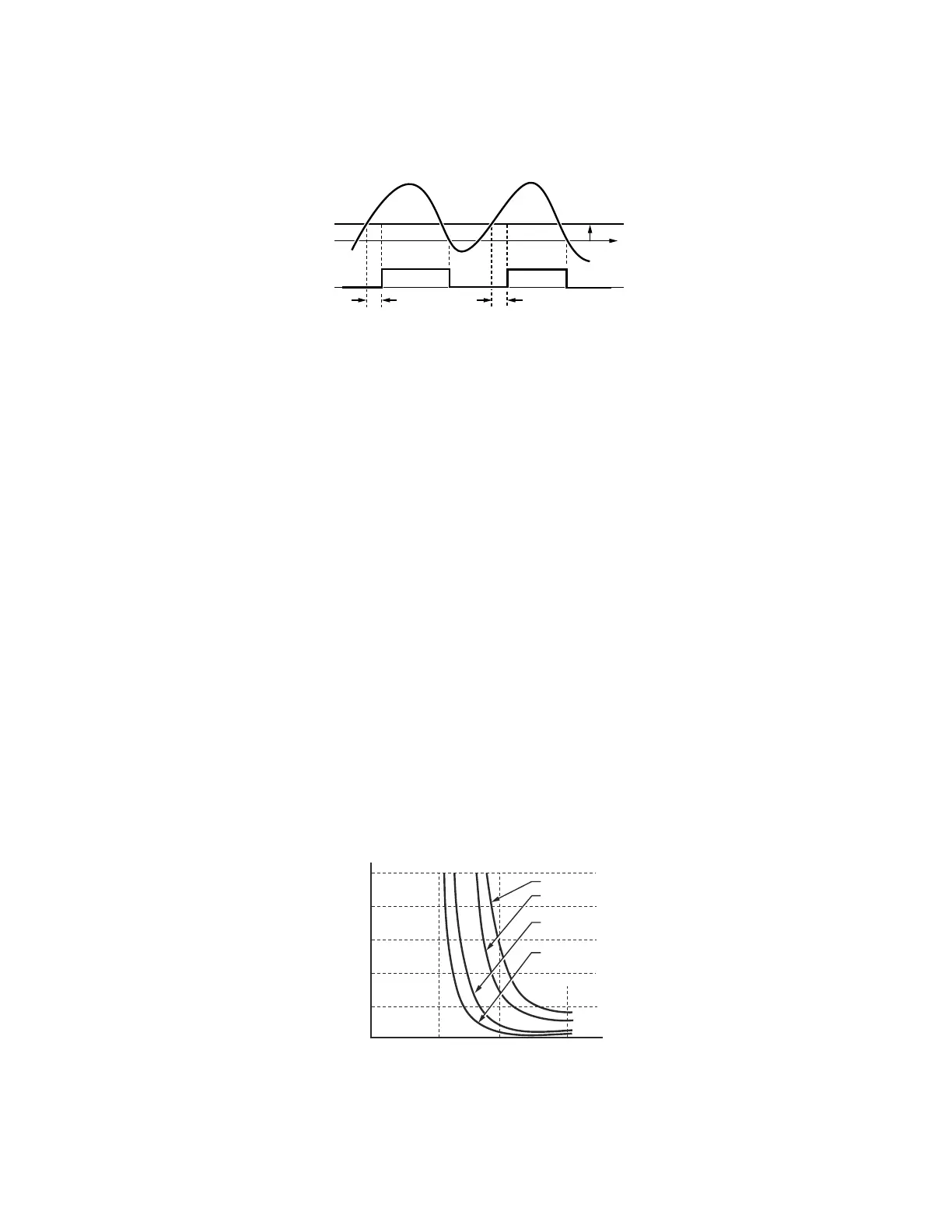

• Over torque detection is determine by the following method: if the output current exceeds the over-torque detection level

(Pr.06-06, factory setting: 150%) and also exceeds Pr.06-07 Over-Torque Detection Time, the fault code “ot1/ot2” will appear.

If a Multi-Functional Output Terminal is to over-torque detection (setting 7 or 8), the output is on. Please refer to Pr.02-13~02-

14 for details.

• This parameter sets the max. current output of the drive.

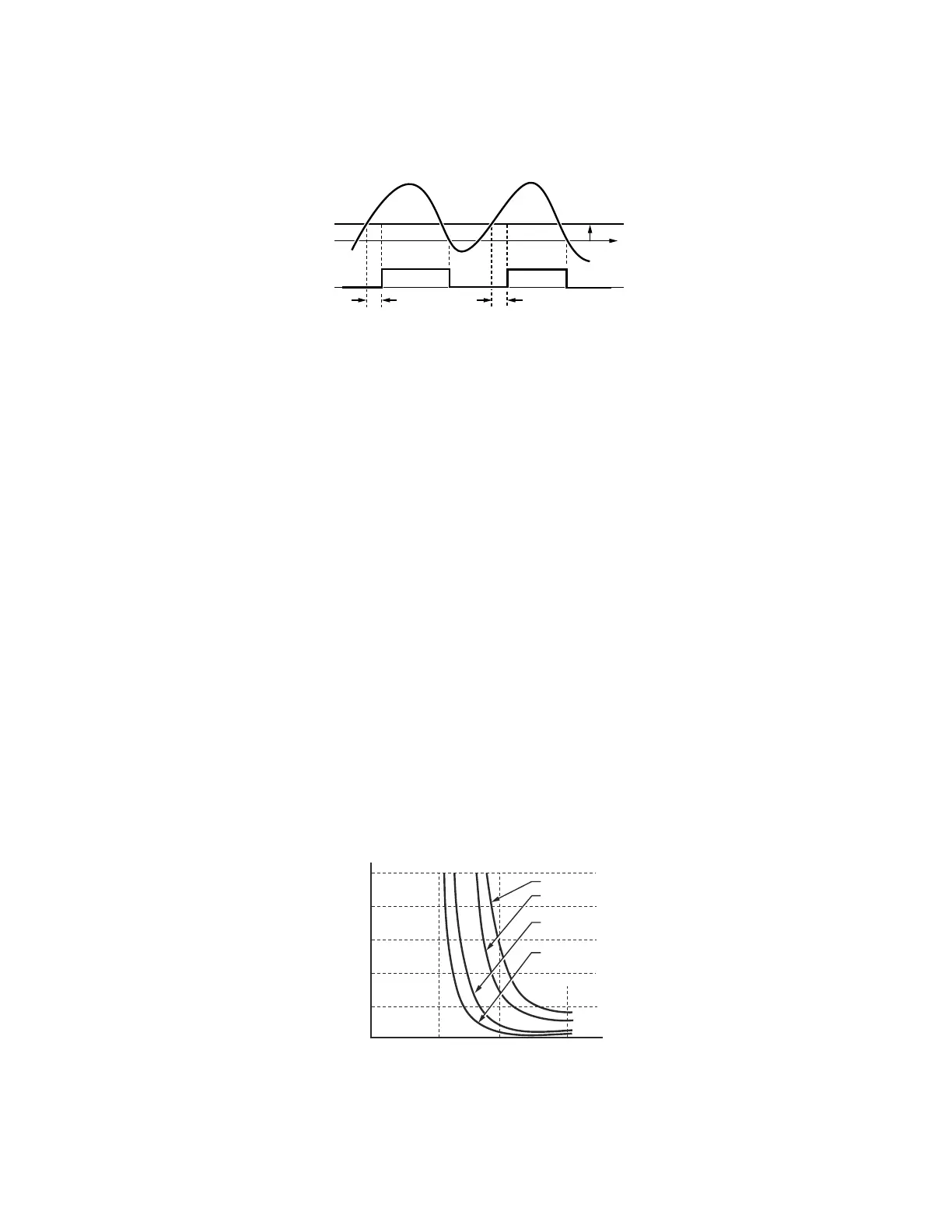

• It is used to prevent self-cooled motor overheats under low speed. User can use electronic thermal relay to limit driver’s output

power.

• The parameter is set by the 150% of motor rated current and the setting of Pr.06-13 and Pr.06-28 to prevent the motor

damaged from overheating. When it reaches the setting, it will display “EoL1/EoL2” and the motor will be in free running.

a

06 - 11 Maximum Current Limit

Factory Setting: 150

Settings 0~200%, 100% drive’s rated current

a

06 - 11 Electronic Thermal Relay Selection (Motor 1)

Factory Setting: 2

Settings 0: Inverter motor

1: Standard motor

2: Disable

a

06 - 13 Electronic Thermal Characteristic for Motor 1

Factory Setting: 60.0

Settings 30.0~600.0 seconds

M33674

PR.06- 06,

PR.06- 09

5%

CURRENT

PR.06- 07, 06-10

M33675

0

1

2

3

4

5

OPERATION

TIME (MIN.)

LOAD

FACTOR (%)

60 Hz OR MORE

50 Hz

10 Hz

5 Hz

20 40 60 80 100 120 140 160 180 200

Loading...

Loading...