CHAPTER 12: DESCRIPTION OF PARAMETER SETTINGS

63-4528—04 202

NOTE: For example, in textile machinery, you will hope that all the machines can be decelerated to stop to prevent bro-

ken stitching when power loss. In this case, the host controller will send a message to the VFD to use dEb func-

tion with deceleration time via EF.

• Pr.07-14 to Pr.07-17 is for heavy load to prevent OV or OC occurs.

• This parameter is used for the fan control.

• Setting 0: Fan will be ON as the drive’s power is turned ON.

• Setting 1: 1 minute after VFD stops, fan will be OFF

• Setting 2: VFD runs and fan will be ON. VFD stops and fan will be OFF.

• Setting 3: Fan run according to IGBT and capacitance temperature. Fan will be ON when preliminary capacitance temperature

is higher than 60

o

C. Fan will be OFF, when capacitance temperature is lower than 40

o

C.

• Setting 4: Fan is always OFF

a

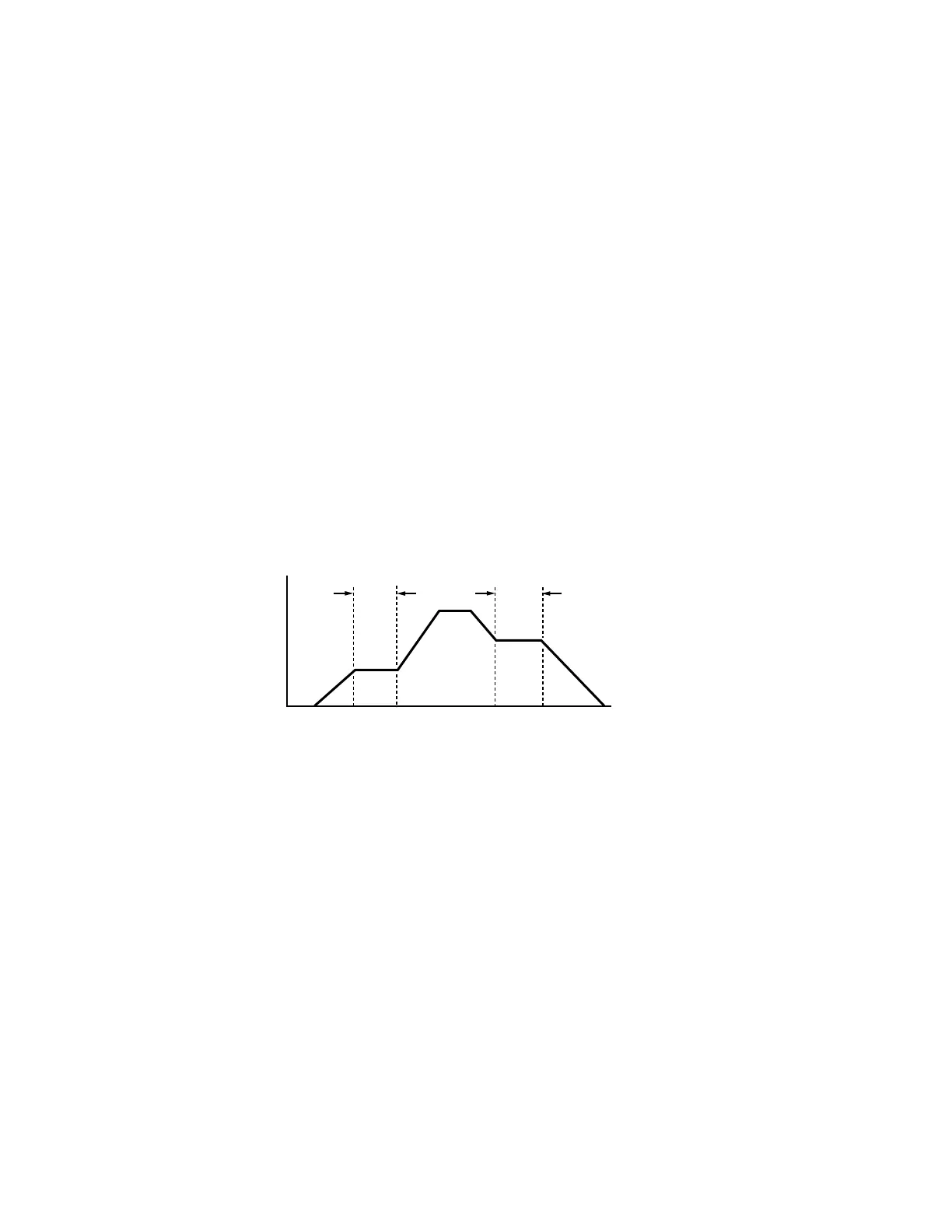

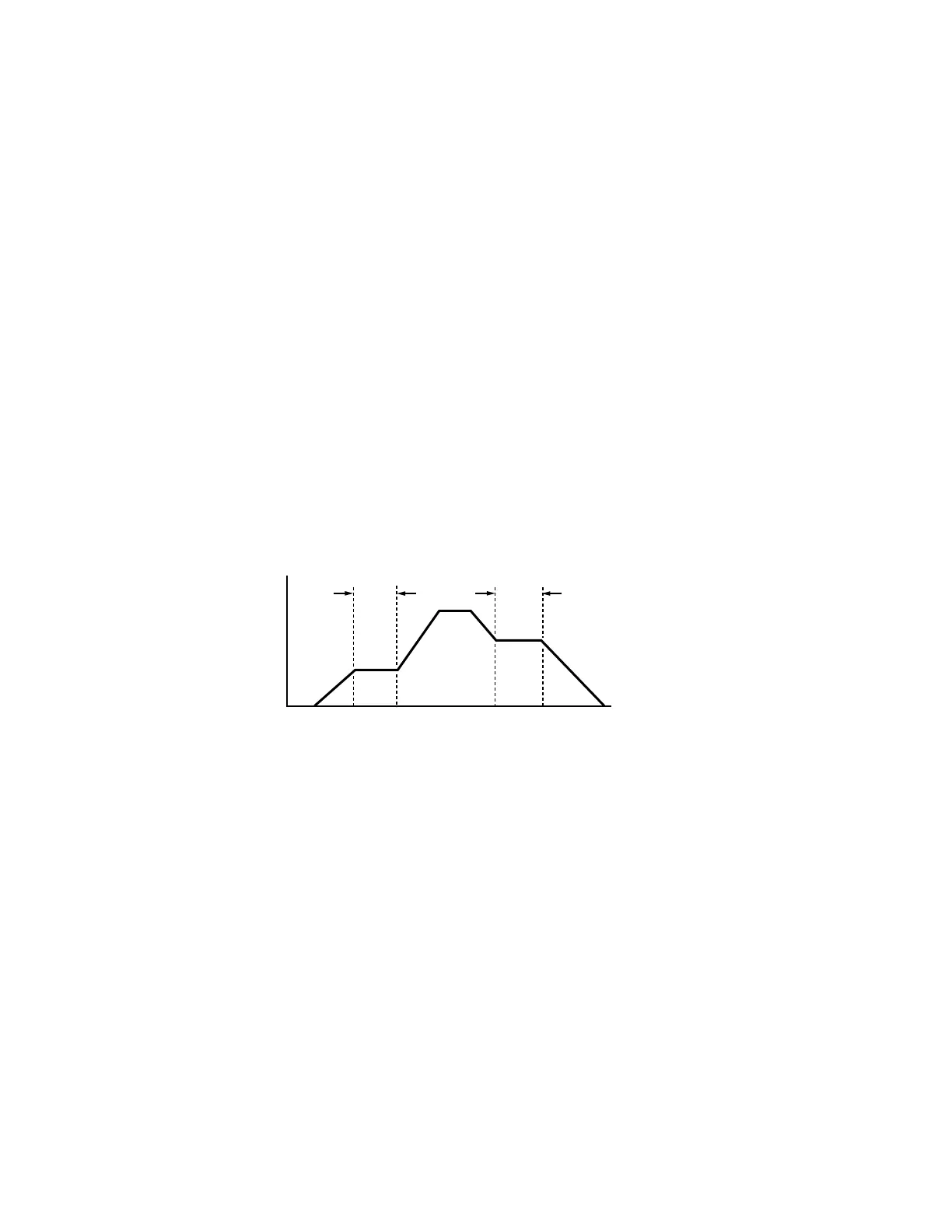

07 - 14 Dwell Time at Accel.

Factory Setting: 0.00

Settings 0.00~600.00 seconds

a

07 - 15 Dwell Frequency at Accel

Factory Setting: 0.00

Settings 0.00~600.00 seconds

a

07 - 16 Dwell Frequency at Accel.

Factory Setting: 0.00

Settings 0.00~600.00Hz

a

07 - 17 Dwell Frequency at Decel.

Factory Setting: 0.00

Settings 0.00~600.00 Hz

a

07 - 18 Fan Cooling Control

Factory Setting: 0

Settings 0: Fan always ON

1: 1 minute after the VFD stops, fan will be OFF

2: When the VFD runs, the fan is ON. When the VFD stops, the fan is OFF

3: Fan turns ON when preliminary heat sink temperature (around 60

o

C) is attained.

4: Fan always OFF

M33687

FREQUENCY

TIME

DWELL AT ACCEL./DECEL.

07-15

DWELL FREQ.

AT ACCEL.

07-14

DWELL

TIME AT

ACCEL.

07-16

DWELL

TIME AT

DECEL.

07-17

DWELL FREQ.

AT DECEL.

Loading...

Loading...