ModelSS28A

Straightness Measurements (

Along

A Hori

zo

ntal Axis)

Misalignment Between Machine Travel

and

the

Laser

Measurement

Axis

(Slope)

Description

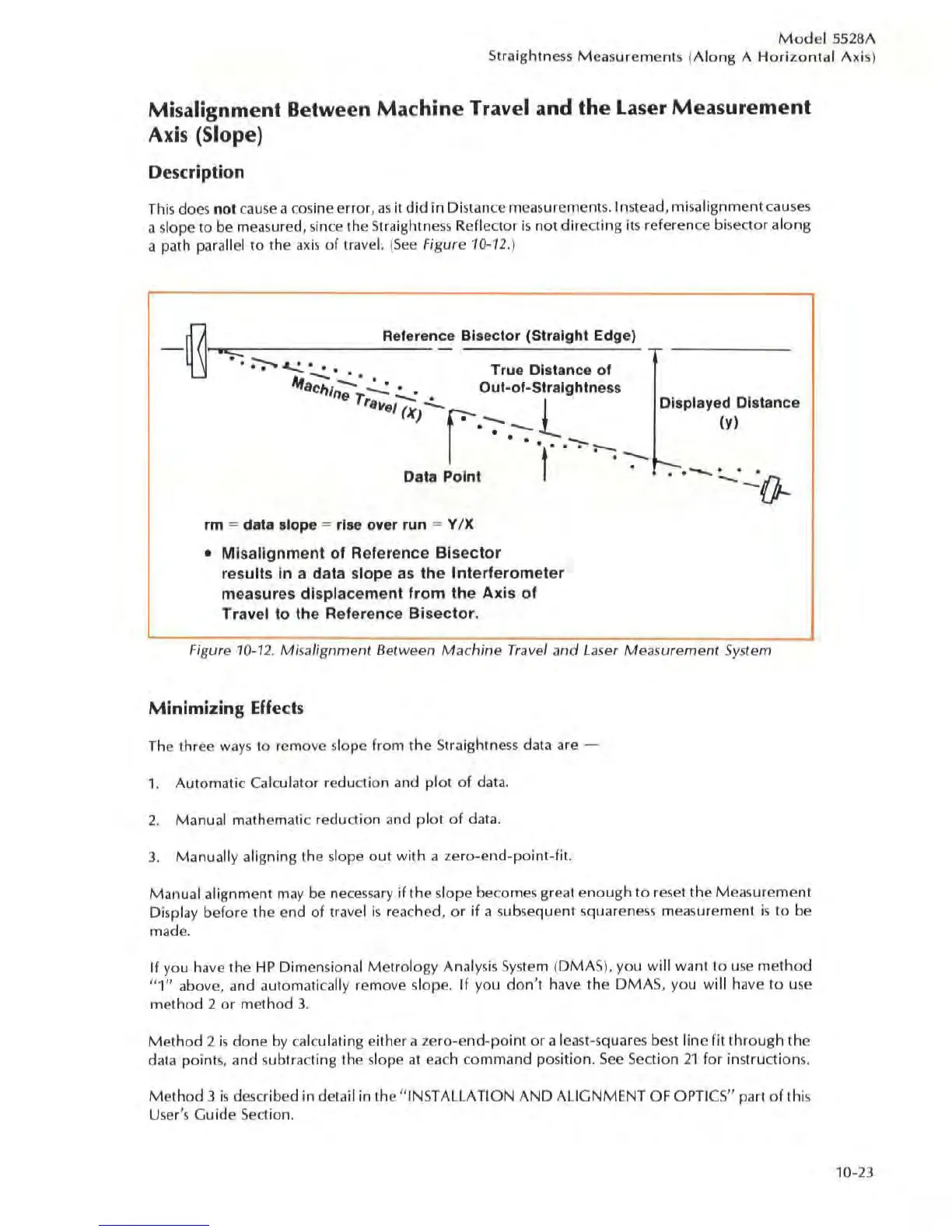

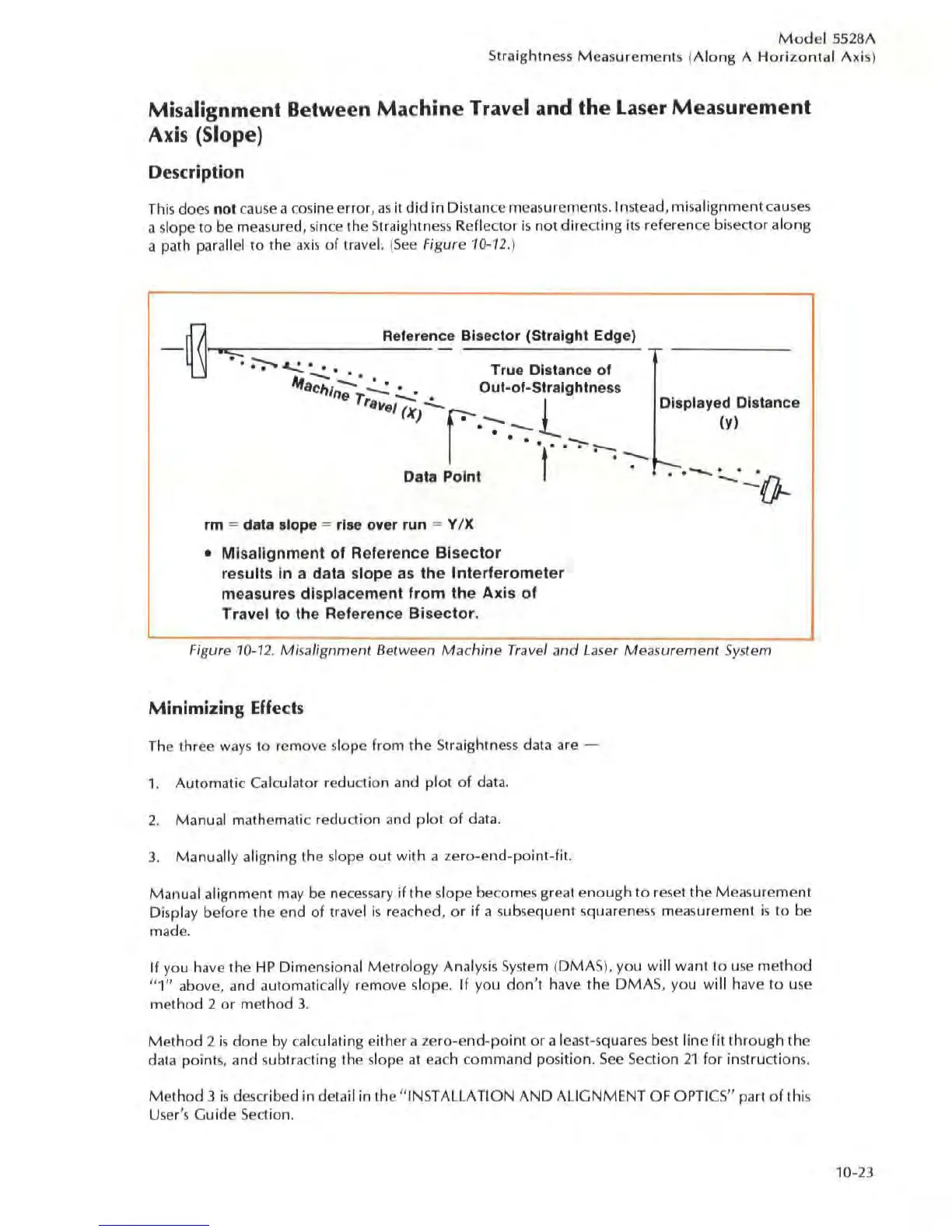

This does not c

au

se

a

cos

ine error,

as

it

did

in Distance measurement

s.

Instead, misalignment causes

a slope to be measured, since the

Straig

htne

ss

Refleoor

is

not

direc

ting Its reference

biseoor

al

ong

a path parallel

to

The

axis

of

travel.

(See

Figure 10-12.)

O

Reference Bisector (Straight Edge)

--

I-~·,,~----

------~~=

..

~

~

..

• - -..:.. • • True Distance of

4t

aC1

I/n";'

T":"':

~

• Out-of-Straightness

ro,./ (Xi -

r.

-:-

.-;

J:-.

-,..

>--

Data Point t

'.

-:-

rm

= data slope = rise over run

""

Y IX

• Misa

lignment

of

Re

ference

Bisector

results

in

a data slope as

the

Interferometer

measures

displacement

from

the

Axis

of

Travel

to

the

Reference

Bisector.

Displayed Distance

(y)

.

--

---

.

...:.!(}-.

Figure

10-12.

Misalignment Between

Machine

Travel

and

La

se

r Measurement System

Minimizing Effects

The thr

ee

ways

to remove slope from the

St

raightness data are -

1. Automatic Calculator reduction and pi

al

of

data.

2.

Manual mathematic reduction and pl

ot of

data.

3.

Manually aligning the slope out with a zero-end-point-fi!.

Manual alignment

may

be ne

cessa

ry

if the slope beco

mes

great

enough

to reset the Meas

urement

Display before the end

of

travel is reached, or

if

a

su

b

se

quent squareness measurement is to be

made.

If you have the

HP

Dimensional

Metrology

Analysis

System

(DMAS), you will want to u

se

method

"1"

above, and automatically remove slope.

If

yO

ll

don',

have the

DMA

S,

you wi

ll

have to use

method

2

or

method

3.

Method

2

is

done

by

calcu l

at

ing either a

zero-end-point

or

a least-squar

es

best line fit through the

data points, and subtra

ct

ing the slope al each comma

nd

position.

See

Section

21

for

instructions.

Me

thod 3 is described in detail in the "INSTALLATION

AND

ALIGNMENT OF OPTICS" part

of

this

User's Guide Section.

10-23

Loading...

Loading...