5 Installation and commissioning

44

HSD S.p.A. © - h0104k01a.fm291119

5.8.4 RS-485 configuration

Access the dip-switches of the electronic device tab, as explained on page 35.

The servo motor communication protocol can be selected using dip-switch DSW1.

Only change the configuration of the dip-switches when the board is not powered up.

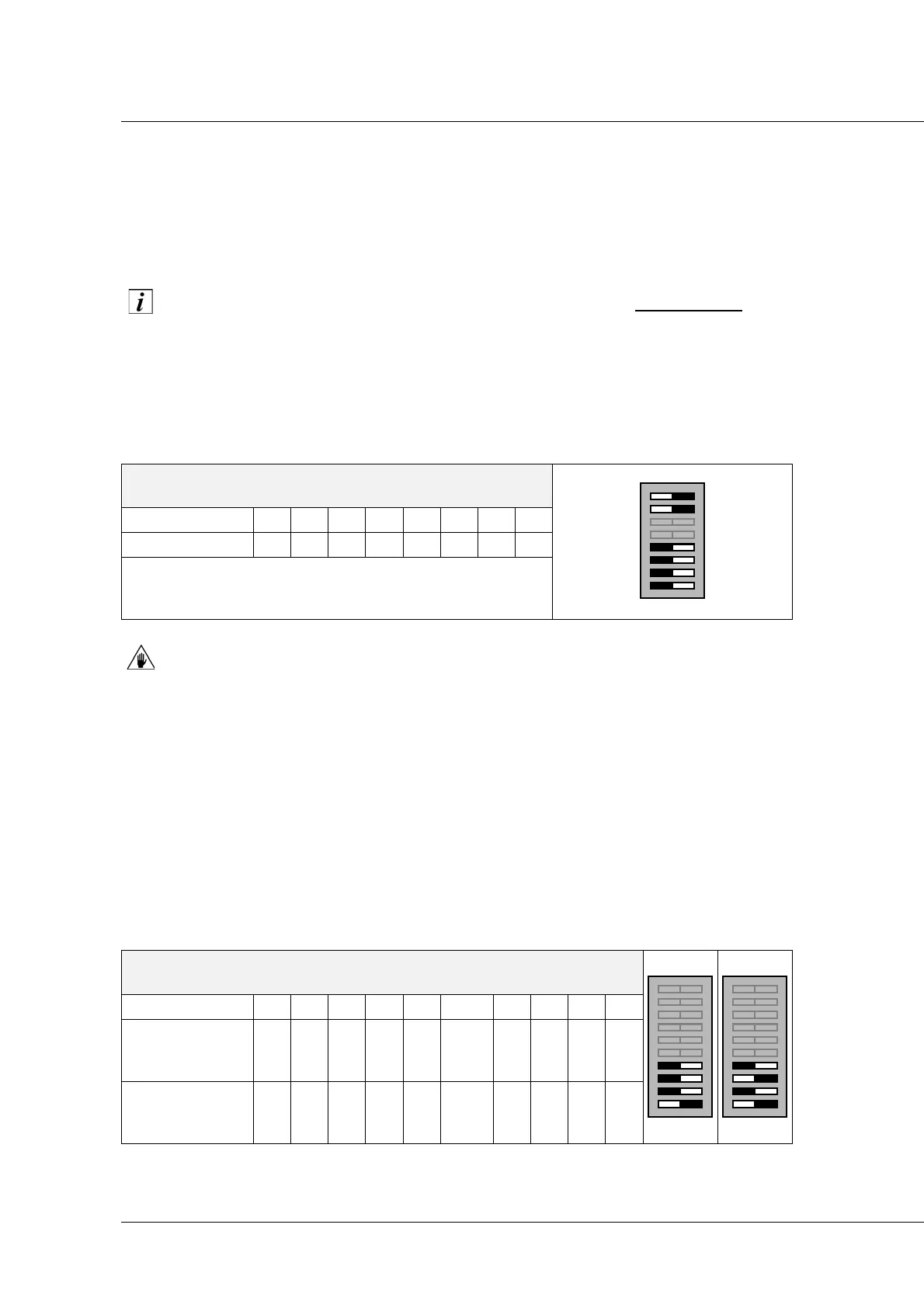

Dip-switch DSW1

To set the RS-485 protocol on the servo-motor, configure the DSW1 switches as shown below.

Switches 3 and 4 are used to terminate the line, which is necessary to avoid signal flip phenomena

on the line.

If switches 3 and 4 are set differently (for example 3 ON and 4 OFF), the module may

not work correctly.

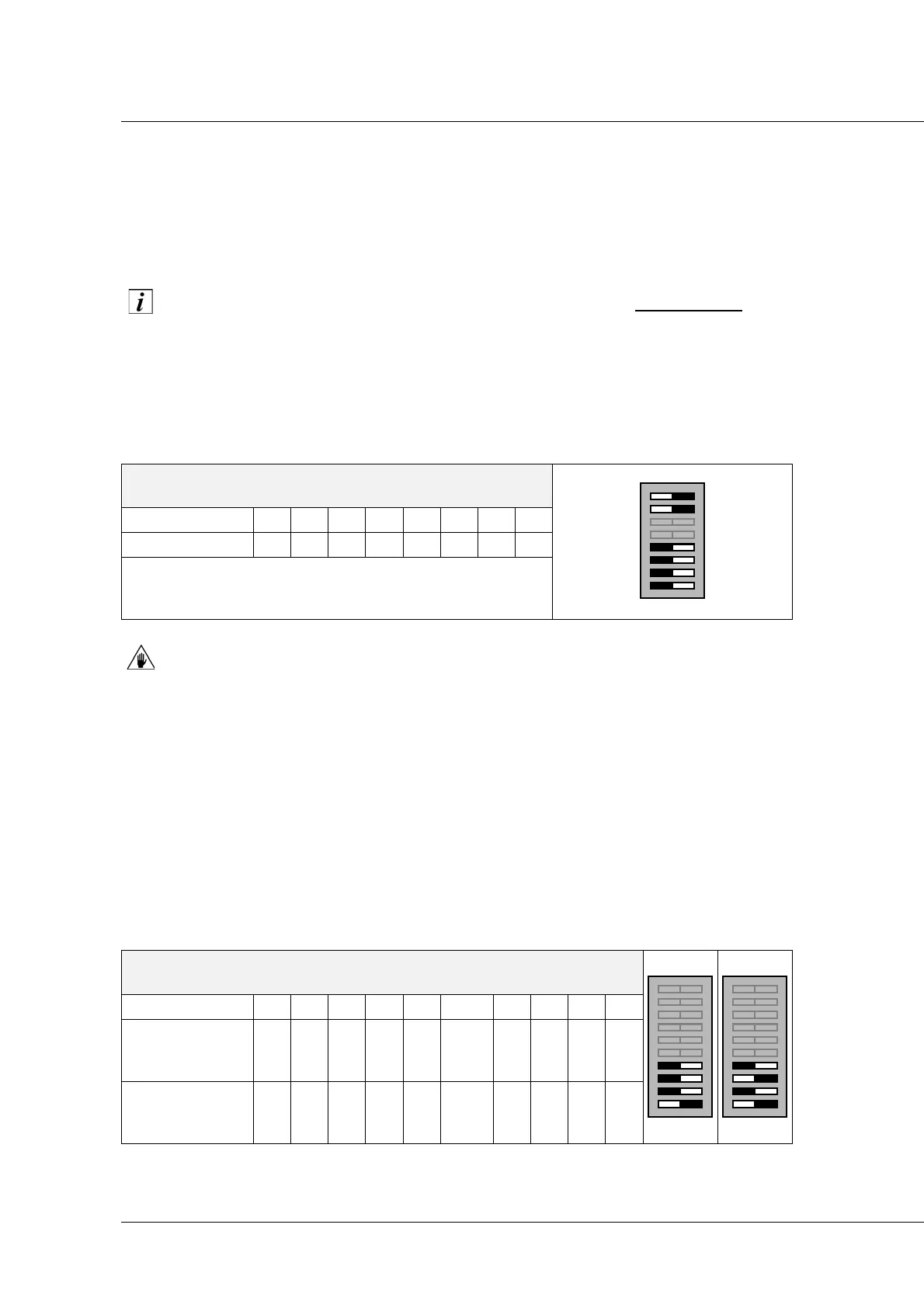

Dip-switch DSW2

The five addressing switches (A0-A4) are used to set the address on the servo-motor Fieldbus. To

set the servo-motor address, enable the switches in such a way that the binary number

corresponds to the required address. Bear in mind that the least important address bit is A0, and

the most important is A4.

Switch 6 is used to set the communication speed which, in the case of the RS-485 protocol, can be

set at 38400 bit/s (ON) or 9600 bit/s (OFF).

Switches 7, 8, 9 and 10 are used to select the servo-motor operating mode and its compatibility

with previous versions, in the event of a replacement.

To do this, refer also to paragraph 5.8.1 “Configuration following a replacement”.

DSW1

Switch 12345678

Position On On T T Off Off Off Off

T = Fieldbus line termination:

set Off if the Fieldbus continue,

set On at the Bus termination.

DSW2

Switch 12345 6 78910

SM 137 D

standard

mode

A0 A1 A2 A3 A4

bit-

rate*

*

Rapid setting of transmission protocol RS-485: ON = 38400 bit/s, OFF = 9600 bit/s.

Off Off Off On

Mode

compatible with

SM 137 C

A0 A1 A2 A3 A4

bit-

rate*

Off On Off On

Loading...

Loading...