PSP8620311

Rev. E

44

!

WARNING

!

WARNING

8 — Maintenance

Service Requirements

The Versa-Tech

®

Recloser has been designed for

a minimum mechanical life of 30,000 operations

(Versa-Tech I) and 10,000 operations (Versa-

Tech LT). No routine maintenance is required

(other than occasional firmware upgrade and

battery replacement).

Battery Replacement

The batteries are made of a very stable lithium

chemistry, which is designed with a low self

discharge with a shelf life of 10 years. Hubbell

Power Systems is recommending that users

replace the batteries on a maximum 8 year cycle

(for Versa-Tech I Reclosers with FW 3.xx and

Versa-Tech LT Reclosers).

Note for Versa-Tech I Reclosers with

FW 4.xx only: Versa-Tech I FW 4.xx

was developed for SCADA compatibility.

It does not incorporate low power

optimization since it requires more

diagnostics and data collection. In cases

of lightly loaded lines, battery power is

utilized to perform these functions

resulting in decreased battery life.

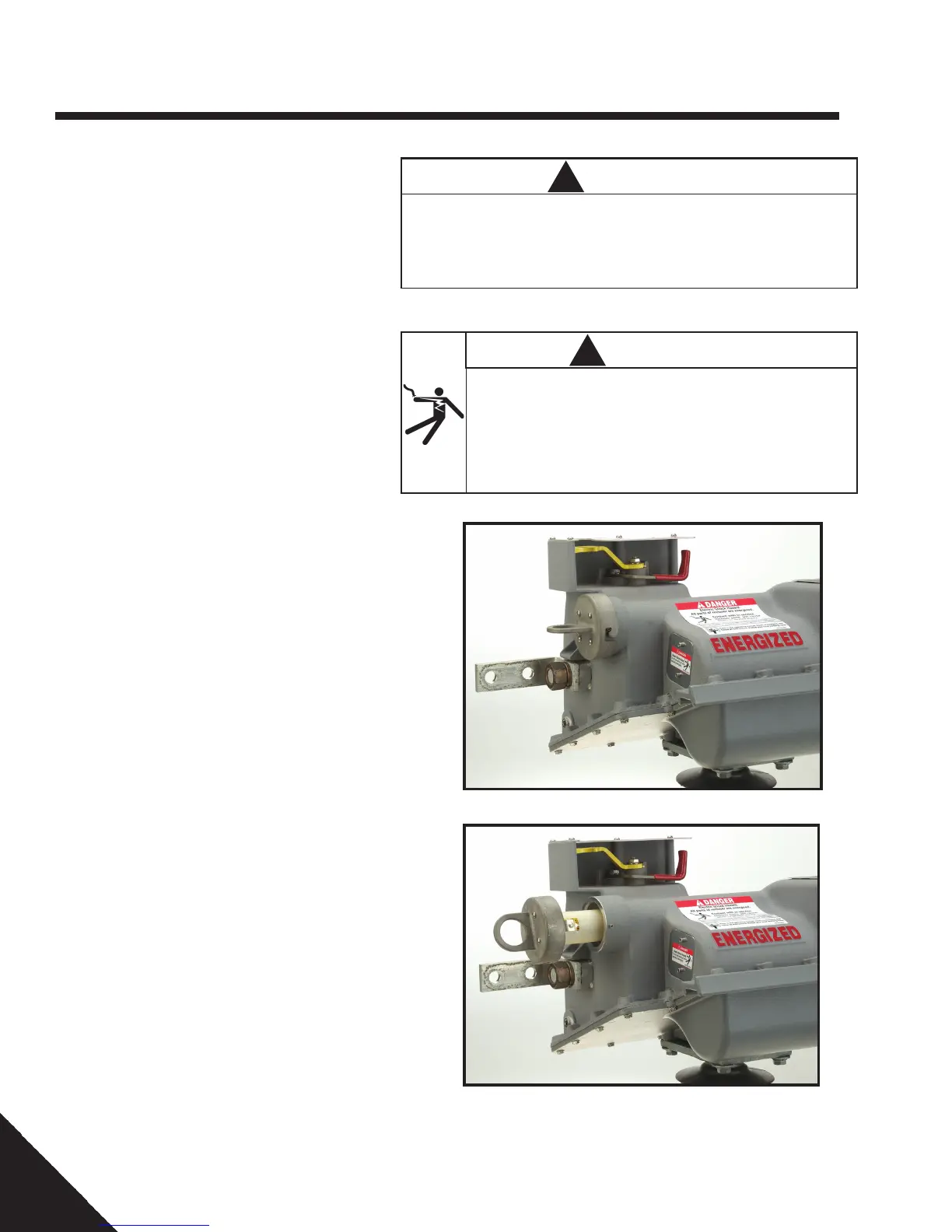

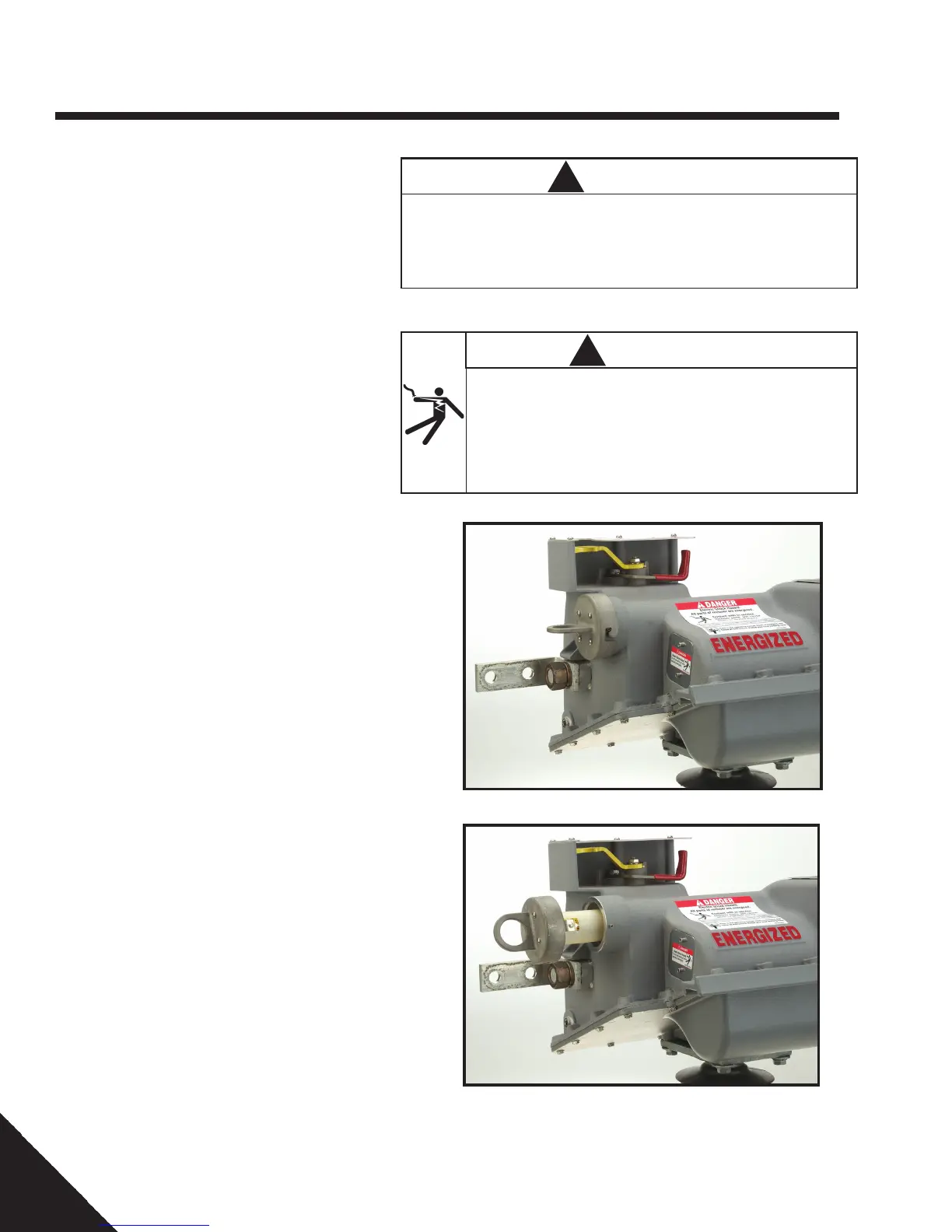

Figures 8-1 and 8-2 show the battery bayonet

and placement in the recloser. The battery

bayonet was designed to be replaced using a hot

stick while the recloser is in service. The battery

bayonet utilizes a twist lock design. It is easily

removed by pushing in slightly and turning.

The date of manufacture of the battery bayonet

is stamped on its end casting. The date format is

"XXXX" where the first two numbers represent

the month and the second two numbers

represent the year.

Figure 8-1 Battery bayonet in the recloser

Figure 8-2 Battery bayonet partially

removed from recloser

Fire, explosion, leakage and severe burn hazard.

Do not recharge or disassemble batteries. Batteries should not be exposed to

temperatures above 212 degrees F. Do not incinerate batteries or expose them to water.

Do not short (+) and (-) terminals of batteries. When discarding batteries, insulate the (+)

and (-) terminals with insulating tape.

High voltage electric contact hazard.

Can cause severe injury or death.

The recloser housing and the battery bayonet are energized when the re-

closer is in service. Follow all of your utility's recommended safety practices

for working with energized apparatus of this voltage class. Use appropriate

length grip-all clamp stick or appropriately rated rubber gloves and personal

protective equipment.

Battery Disposal

Litihium batteries are neither specifically listed nor

exempted from the Federal Environmental Protection

Agency (EPA) hazardous waste regulations as

promulgated by the Resource Conservation and

Recovery Act (RCRA). The only metal of possible

concern in a lithium battery is lithium that is not a listed

or characteristic toxic hazardous waste. Waste lithium

batteries can be considered a reactive hazardous

waste if there is a significant amount of unreacted, or

unconsumed lithium remaining in the spent battery.

The key to disposing of a lithium battery as a non-

hazardous waste is to guarantee that it is fully or

mostly discharged. Once it is discharged it can be

disposed of as non-hazardous waste.

Loading...

Loading...