Electronic Overspeed Switch EGS 40

EGS40_MANUAL-en_R6(2018-11-07)ID74528.docx

6.2 Installation tasks

6.2.1 Device execution for flange design (B5) or foot design (B35)

1. Use a play-free coupling.

2. Ensure precise catered attachment, particularly with foot design B35 (double coupling HKD5 is

recommended).

3. Fix device in place via flange or foot.

4. Make the connections in the terminal box ( Appendix, Connection diagrams).

6.2.2 Assembly instruction no. 54690 for coupling type HK….5

1. Select coupling bore with G7 fit (tolerance field is above the zero line).

2. Push the coupling onto the shaft with easy movement. Finishes ream the associated bore if

necessary.

3. Secure the hub against axial offset with M4 radial set screw (with tip). The set screw presses

on the feather key so that the shaft is not damaged.

Consider the permissible compliance:

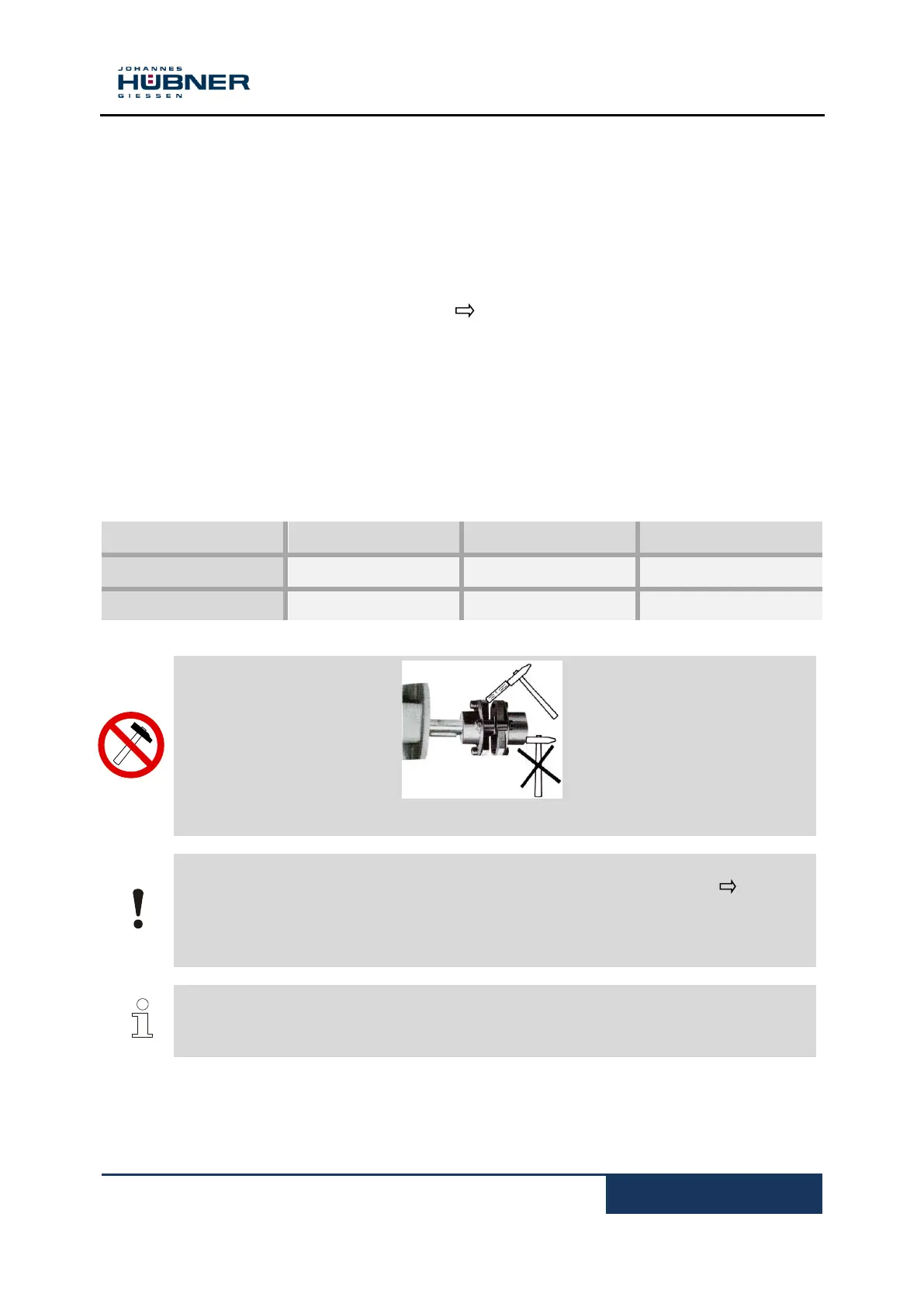

CAUTION!

Danger of damage or breakage if the coupling is not improperly handled ( Fig. 1).

No hard impacts on coupling and shaft

Do not deform the coupling

Do not exceed compliance as specified

Precisely align coupled machines

NOTE

The more precise the attachment,

the longer the service life of the coupling and bearing encoder

and the lower the degree of influence on encoder signal quality (harmonics)

Additional instructions on couplings are provided in the current Hubner Giessen catalog "Torsion-

resistant stiff couplings for encoders".

Loading...

Loading...