51 52

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I PILOT VALVE REPLACEMENT

SOLENOID & PILOT VALVE ASSEMBLY REMOVAL I TABLE OF CONTENTS

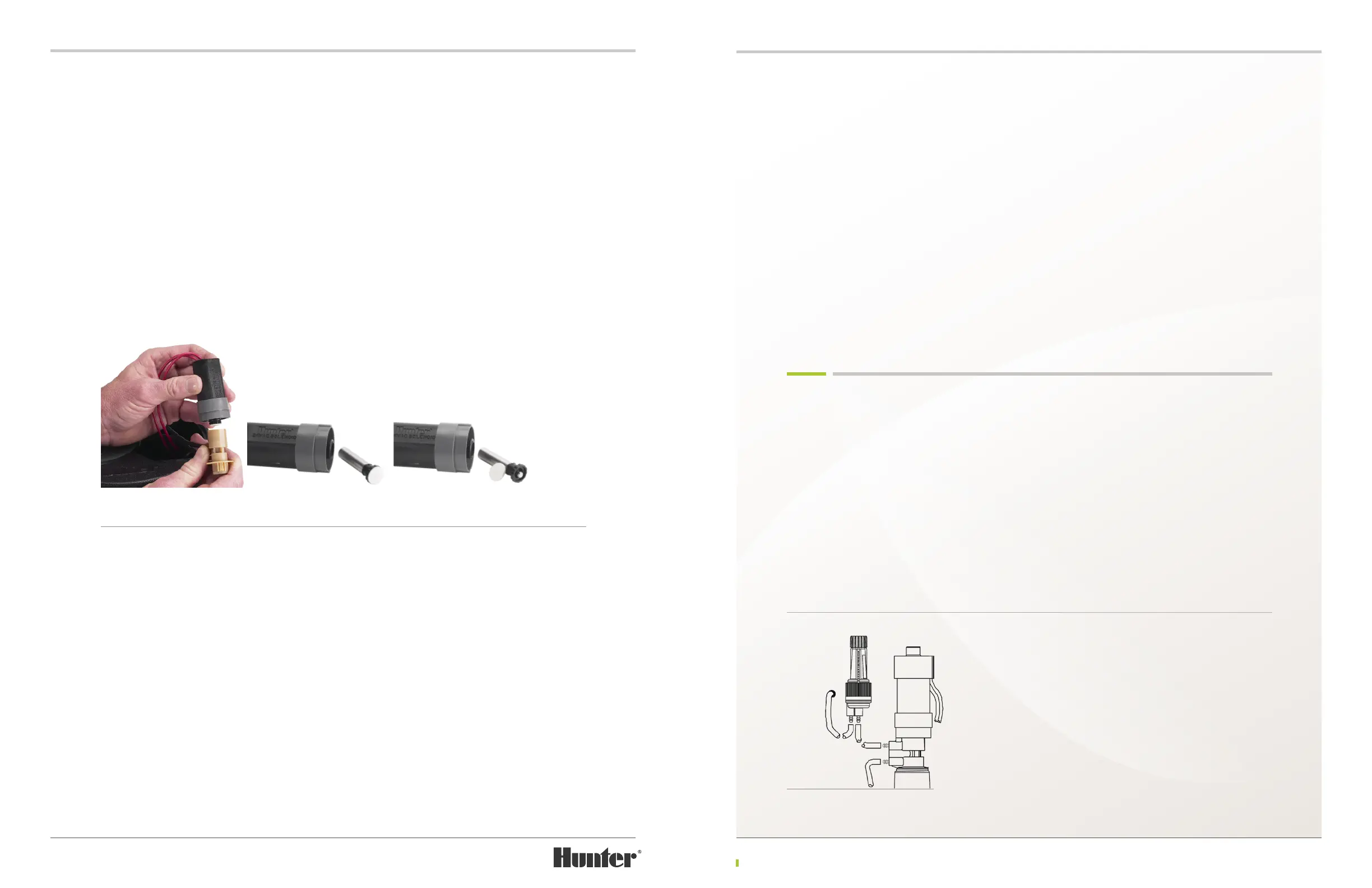

The plunger assembly is retained within the Solenoid with a secure snap-t feature. To remove the

plunger assembly, rst notice there is a black knurled ring just below the solenoid’s rubberized

seat-seal. Just below the black knurled ring is a black O-Ring. The plunger assembly can be removed

by forcing the thumb-nail under the black knurled ring and pulling to separate the plunger

assembly from the solenoid (FIGURE 134). Alternatively, a small at bladed screwdriver can be

inserted below the black knurled ring and twisted to release the plunger assembly. Use care not to

damage the black O-Ring. If the plunger assembly does not stay assembled when removed from

the solenoid, it is necessary to replace the Plunger assembly.

Rinse the plunger assembly and solenoid with clean water to remove any contaminating debris. If

damage or worn, replace black O-Ring and/or rubberized seat-seal (FIGURE 135). Insert plunger

assembly into the solenoid and then press to engage the snap-t feature. Finally, press on the

seat-seal to cycle the plunger assembly. If plunger does not cycle up and down freely, repeat

cleaning procedure and/or replace the plunger assembly.

Solenoid Replacement – It is not necessary to dig around the rotor to replace in-ground solenoid

wire splice connections if there is condence in both the quality of the splices and the type of

connector used. It is absolutely not necessary to dig around the rotor to replace the solenoid wire

splice connections if the original connecting splices were completed within the rotor’s ange

compartment.

In-ground with questionable wire splice connections – dig around the rotor to access the solenoid

splice connections. Remove the connectors. If possible, run controller wires into the rotor’s ange

compartment and splice wires to solenoid’s wires using appropriate grease-lled connectors.

If not possible, feed replacement solenoid’s wiring through hole at the bottom of the ange

compartment. Splice controller wires with solenoid’s wires using appropriate grease-lled

connectors. Choose either of the Hunter DC solenoid’s lead wires when making each splice as

there is no specic polarity required.

IMPORTANT – the TTS rotor’s top service capabilities require that there is sucient slack in the

Solenoid’s wiring leads within the ange compartment. To estimate required wiring slack, bring

Solenoid to the top of the rotor’s ange. During back-ll of soil around rotor, do not let the

Solenoid be pulled into the ange compartment.

In-ground good quality wire splice connections –

Hold the defective solenoid in one hand and

cut the defective Solenoid’s two lead wires at

a point close to the defective solenoid. Splice

the lead wires from the defective solenoid to

the new solenoid’s lead wires using appropriate

grease-lled connectors. If needed, the new

Solenoid’s lead wires can be shortened to

minimize excess wiring within the ange

compartment.

Flange compartment wire splice connections –

If original wire splice connections were made

within the ange compartment, simply disconnect

splices and re-splice controller wiring to the

new Solenoid’s wiring leads. Conrm that

appropriate grease-lled type connectors are in

use. If not, discard and replace with appropriate

connectors. If needed, the new Solenoid’s lead

wires can be shortened to minimize excess

wiring within the ange compartment.

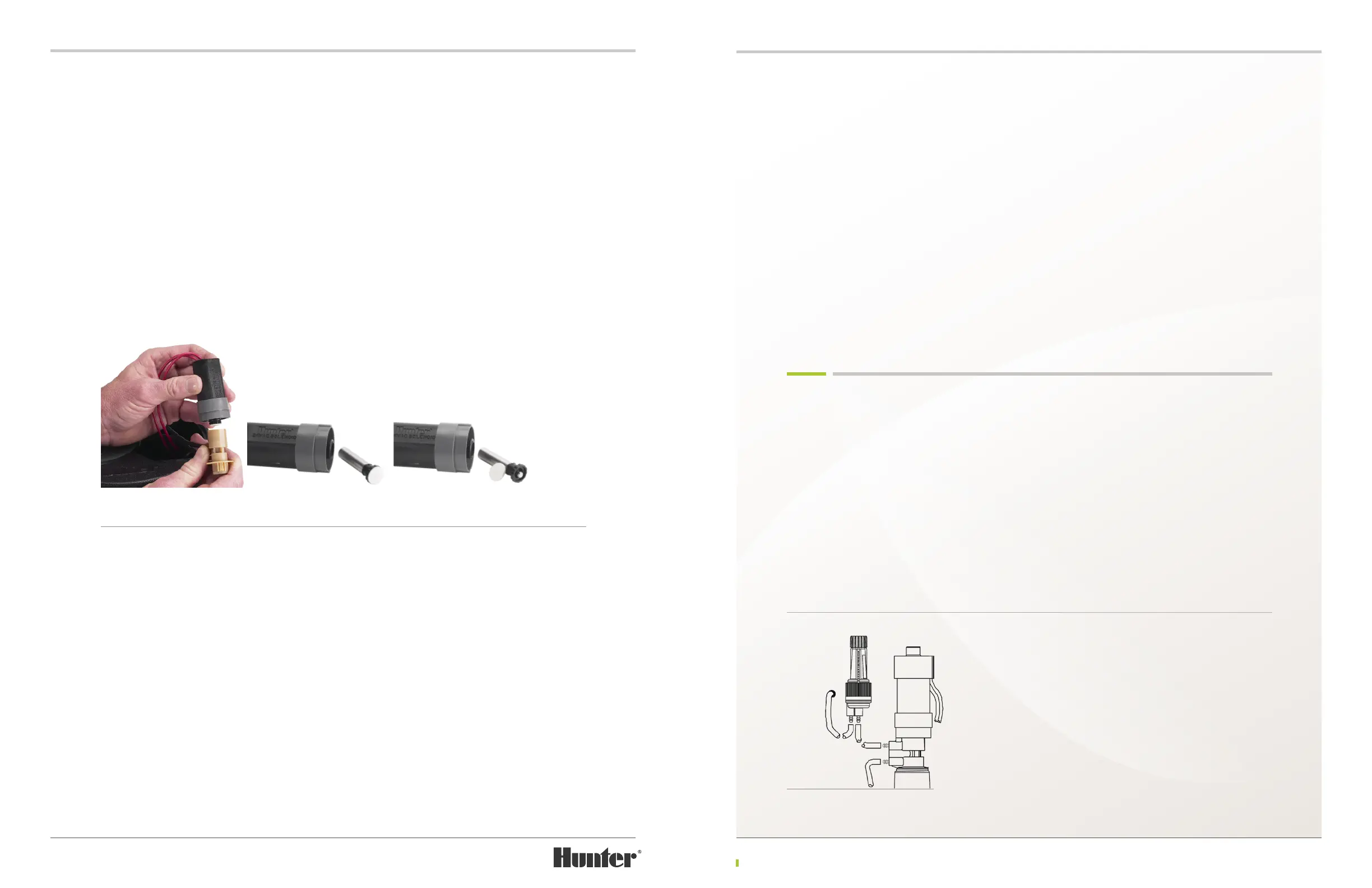

PILOT VALVE REPLACEMENT

See the warning above regarding rotor activation

when Solenoid is loosened or Pilot Valve tubing

is disconnected. There are no serviceable parts

within the TTS rotor’s Pilot Valve assembly. If

the lter inside the Pilot Valve becomes

obstructed, the water ow through the Pilot

Valve can be reduced. A substantial reduction in

water ow through the Pilot Valve will prevent

the rotor’s Inlet Valve from opening fully.

Notice the two tubes attached to the Pilot

Valve’s ttings (FIGURE 136). The lower tting is

the inlet and the upper tting is the outlet. The

lower tube is the pressurized supply tube that

comes from the rotor’s Inlet Valve at the bottom

of the rotor. The upper tube goes from the Pilot

Valve to the inlet of the pressure regulator. To

replace the Pilot Valve, use side-cutters or blade

to make clean cuts at points just before the

ttings on the Pilot Valve. Trim & remove the

remaining tube from ttings.

FIGURE 133 FIGURE 134 FIGURE 135

FIGURE 136

Loading...

Loading...