49 50

Learn more. Visit hunterindustries.com/golf

TABLE OF CONTENTS I SOLENOID & PILOT VALVE ASSEMBLY REMOVAL

SOLENOID & PILOT VALVE ASSEMBLY REMOVAL I TABLE OF CONTENTS

SOLENOID & PILOT VALVE ASSEMBLY REMOVAL

In order to work on the Solenoid or the Pilot Valve, it is rst necessary to remove the connected

Solenoid and Pilot Valve assembly from the ange compartment. Prior to removal, take note of

the orientation of the ttings and tubing that are attached to the Pilot Valve. This will help with

nal assembly later.

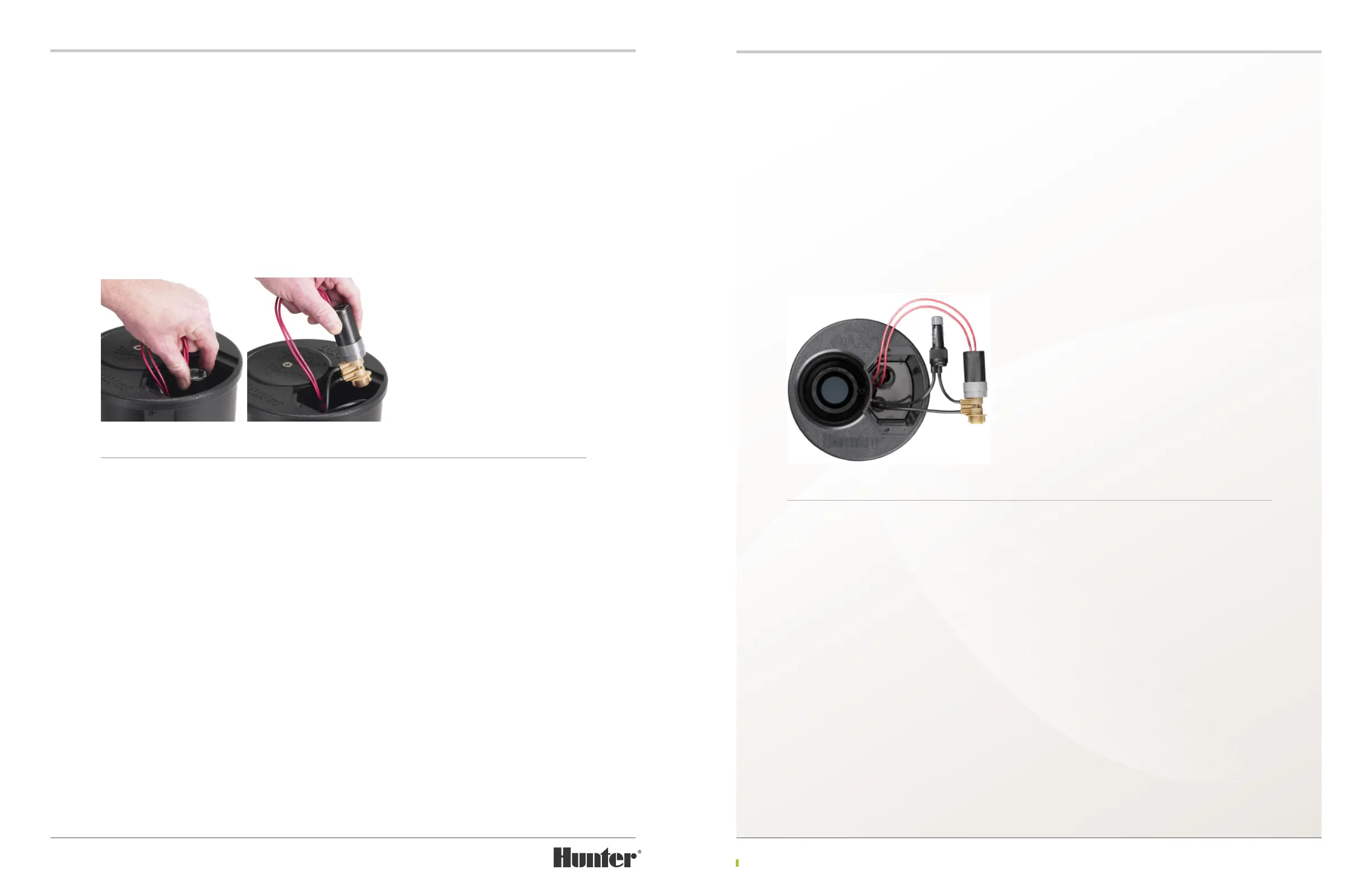

To remove the Solenoid and Pilot Valve from the ange compartment, grab the Solenoid and

wiggle it back and forth while liing upwards (FIGURE 130). Pull the Solenoid and Pilot Valve

assembly up and on top of the rotor’s ange (FIGURE 131).

SOLENOID SERVICING AND REPLACEMENT

Preventing Sprinkler Activation –

See the warning above regarding rotor activation when Solenoid is loosened or removed.

There are three ways to prevent activation of the rotor when the Solenoid is removed from the

Pilot Valve:

The best and most eective way is to shut down the main line or the sub-main line water

supply to the rotor that is being serviced. Be aware that residual pressure may reside in the

system piping even aer that valve has been closed. To purge residual pressure, activate a rotor or

quick-coupler near to the rotor being serviced or, move the selector to the manual On position.

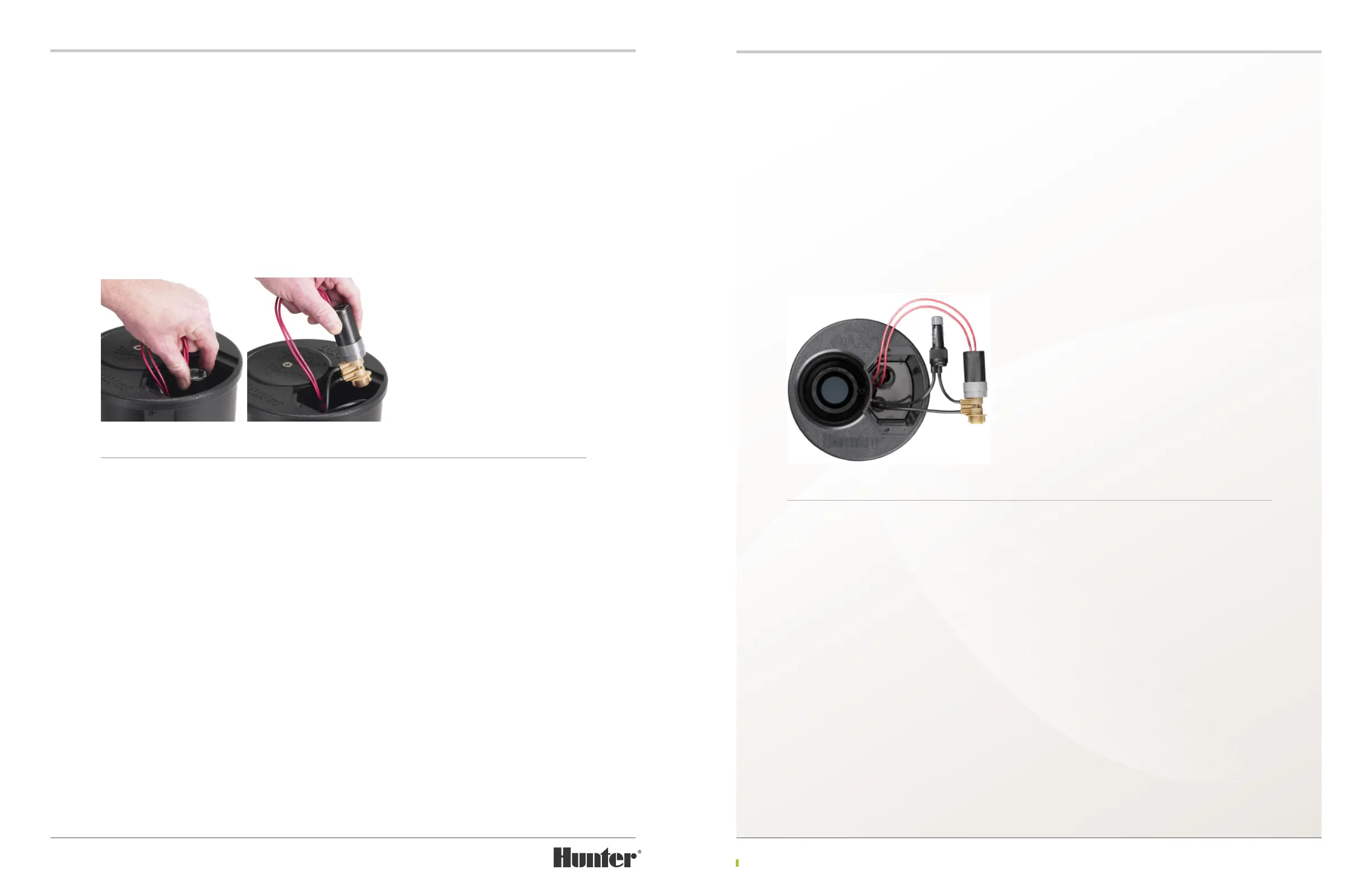

A tubing clamp or locking forceps tool can be used to pinch the supply tube going into the Pilot

Valve. The pressurized supply tube runs from the inlet area of the rotor and up into the ange

compartment, then is directly connected to the bottom tting on the Pilot Valve (FIGURE 132).

Caution – care needs to be taken and an appropriate tool used to avoid damaging the tubing as it

is clamped closed. A leaking supply tube will cause the rotor to weep water while deactivated.

A ¼” tubing retainer can be used to pinch the

supply tube going into the Pilot Valve. Note that

the tubing used within the TTS rotor’s ange

compartment is ⅛” tubing, NOT ¼” tubing. To

do so, bend the supply tubing together and slide

the tube retainer over the bent end to hold the

tubing closed. The pressurized supply tube

runs from the inlet area of the rotor and up

into the ange compartment, then is directly

connected to the bottom tting on the Pilot

Valve (FIGURE 132).

Caution – care needs to be taken so as to avoid damaging the tubing as it is bent closed. This

procedure is not recommended in cold weather conditions. A leaking supply tube will cause the

rotor to weep water while deactivated.

Separate the Solenoid from the Pilot Valve -

Remove the Solenoid from Pilot Valve with

counter-clockwise turns. Pull to separate the

Solenoid from the Pilot Valve (FIGURE 133). The

gray plastic part at the base of the Solenoid

is called the Detent Ring. When the Solenoid

is attached to the Pilot Valve, the Detent Ring

interacts with the Pilot Valve to create the Auto

position’s detent (the stopping point when

moving the Selector Cap to the Auto position).

Under normal operating conditions, the Detent

Ring will not need replacement. If the solenoid

needs to be replaced, it will also be necessary

to replace the detent ring.

Solenoid Servicing – The Plunger assembly

and the rubberized Seat-Seal are serviceable on

Hunter Solenoids. To replace a worn or damaged

rubberized Seat-Seal, simply pull the old one

o and press the new one into position on the

Solenoid’s Plunger. Since a worn or damaged

rubberized Seat-Seal can cause the rotor to

weep water when the rotor is deactivated, it is

highly recommended that the rubberized Seat-

Seal be replaced whenever servicing the Plunger

assembly.

FIGURE 130 FIGURE 131

FIGURE 132

Loading...

Loading...