MAINTENANCE WORK ON CHASSIS AND ENGINE

- 53 -

ENGLISH

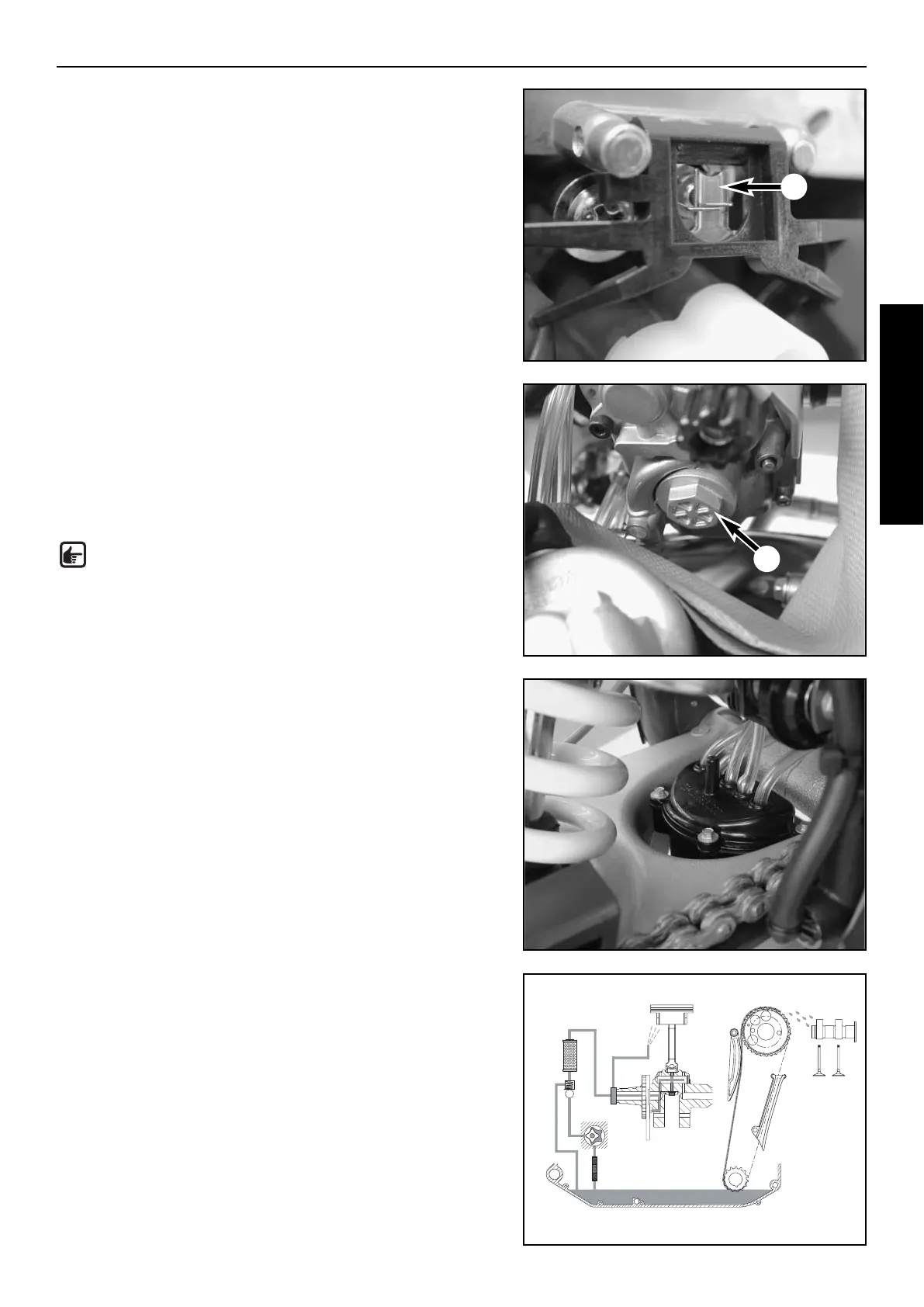

CHECKING THE FLOAT LEVEL (FLOAT HEIGHT) *

For this purpose, dismount the carburetor and remove the float chamber.

Hold the carburetor in a slanted position such that the float will abut the

float needle valve but not compress it.

In this position, the edge of the float should be parallel with the float cham-

ber sealing surface (see illustration).

If the float height does not correspond to the desired value, check the

float needle valve and, if necessary, replace it.

If the float needle valve is o.k., you can adjust the float height by bending

the float lever (1).

Mount the float chamber, install the carburetor, and adjust the idle speed.

DRAINING THE FLOAT CHAMBER OF THE CARBURETOR *

Following every wet cleaning procedure, the float chamber of the carbu-

retor should be drained in order to remove any water that may have pene-

trated into it. Water in the float chamber causes engine malfunction.

Perform this task on a cold engine. Close the fuel tap, and place a cloth

underneath the carburetor, which is able to absorb any escaping fuel.

Unscrew the plug (2), and clean it with compressed air. Then, mount the

plug together with its gasket, open the fuel tap, and check the float cham-

ber for any leaks.

NOTE: Fuel is easily flammable and toxic. When handling

fuel, be sure to exercise the utmost caution. Never perform

any work on the fuel system near open flames or burning

cigarettes.

Always allow the engine to cool off first. Immediately clean

up any fuel which may have been spilled. Materials satura-

ted with fuel are also easily flammable. In case you ingested

fuel or fuel splashed into your eyes, consult a doctor

immediately.

Dispose of the fuel properly.

INTERCEPTING TANK FOR THE CARBURETOR VENTILATION:

To prevent fuel from running out after a fall, mount the intercepting tank

(included) for racing purposes. Screw the intercepting tank (1) to the bot-

tom of the frame crossrail using the clamp and HH collar screws.

A drain plug is located on the bottom to drain the tank.

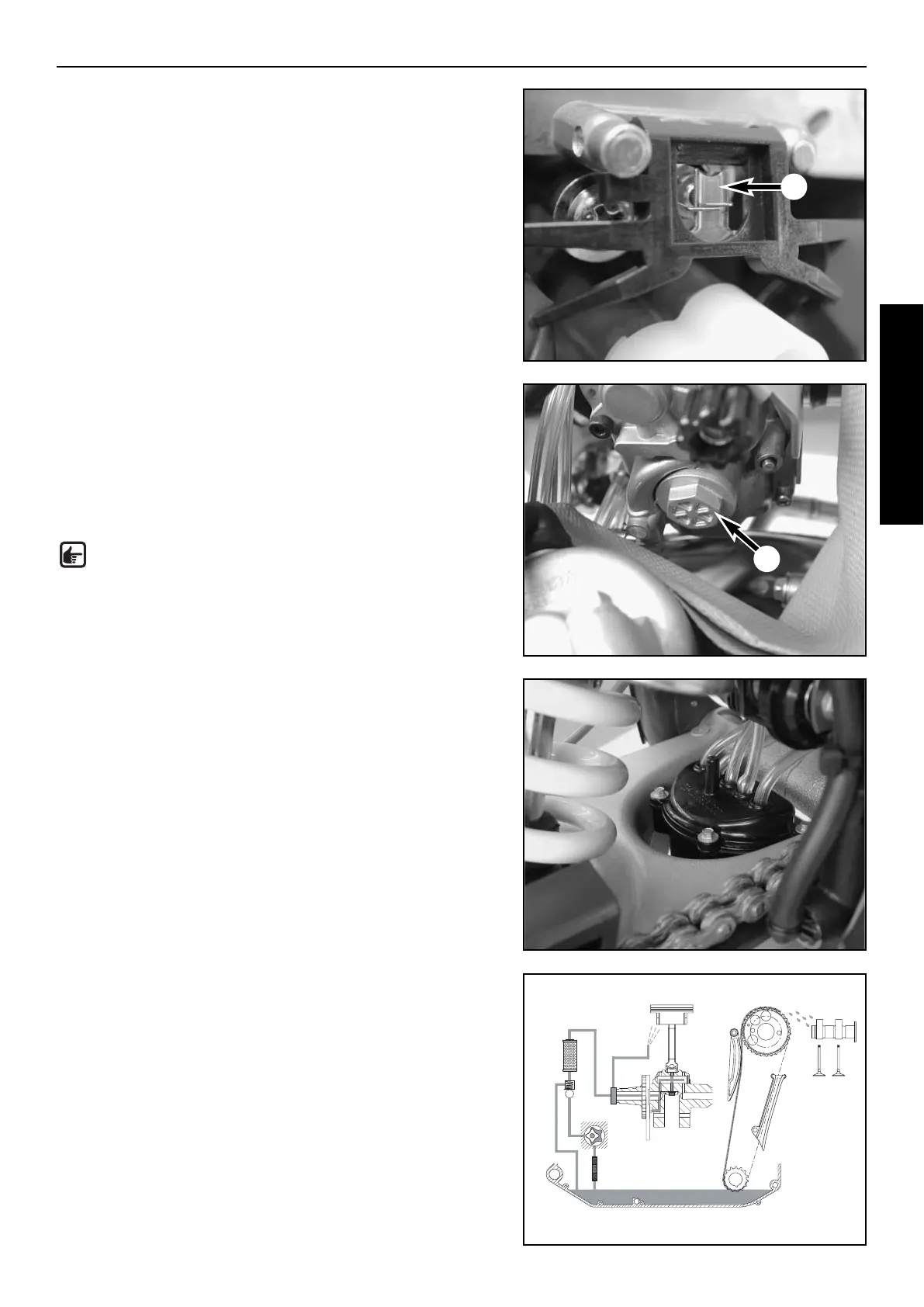

OIL CIRCUIT

The oil pump (4) draws the engine oil from the oil sump through the oil

screen (5) and pumps it past the pressure relief valve (6) to the oil filter

(7). It continues to the crankshaft (8), partly branching off through a hole

to lubricate and cool the piston (9) and the piston pin bearing. Once

through the crankshaft, the engine oil is pumped to the conrod bearing

(10) and branches off again to the bearings in the balance weight (11).

The camshaft (12) is lubricated by the engine oil which is transported to

the cylinder head by the timing chain (13).

On the downward movement of the piston, engine oil is pressed from the

crankcase through the diaphragm valve (not depicted) to the transmis-

sion and shift mechanism.

1

2

12

11

10

4

5

6

7

8

9

13

Loading...

Loading...