SERVICING THE INDIVIDUAL PARTS

D

18

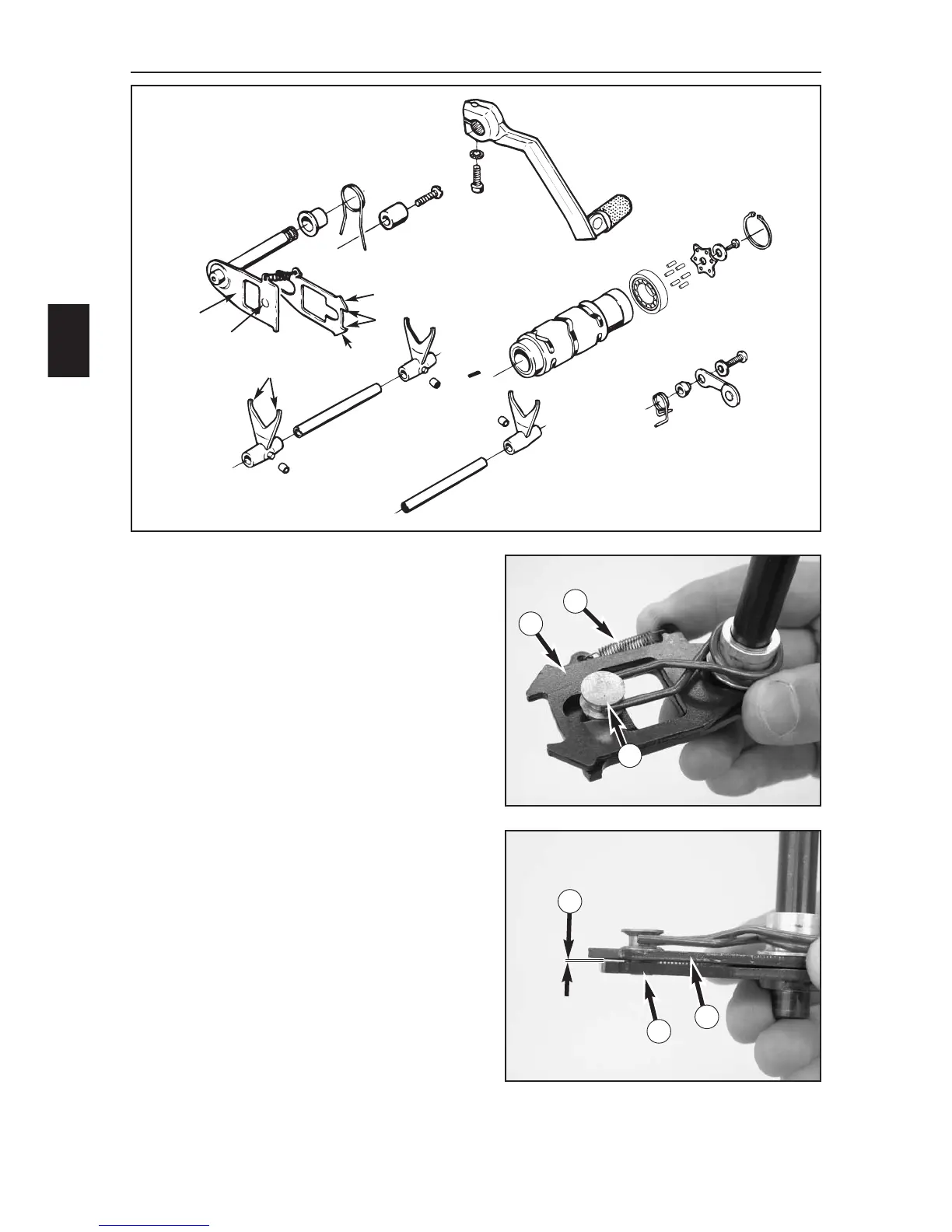

SHIFT MECHANISM

– Disassemble the shift shaft and clean the individual

parts.

– Check the shift forks (1) at the blade (A) for wear. They

are 3.9 mm thick when new; the wear limit is 3.6 mm.

– Check the shift grooves on the shift drum (2) for wear.

– Check whether the shift drum is properly seated in the

grooved ball bearing (3).

– Check the grooved ball bearing (3) for smooth

operation.

– Check the shift rollers (4) for pressure marks or cracks.

– Check the shift rails (5) for runout on a flat surface.

Also check for scores or seizing marks. Make sure the

shift forks run smoothly on the shift rails.

–

Check the shift rail (6) for wear at the points of contact (B).

– Check the return surface (C) on the shift rail for wear

(replace if excessively grooved)

– Check the guide bolt (D) for a tight fit and wear.

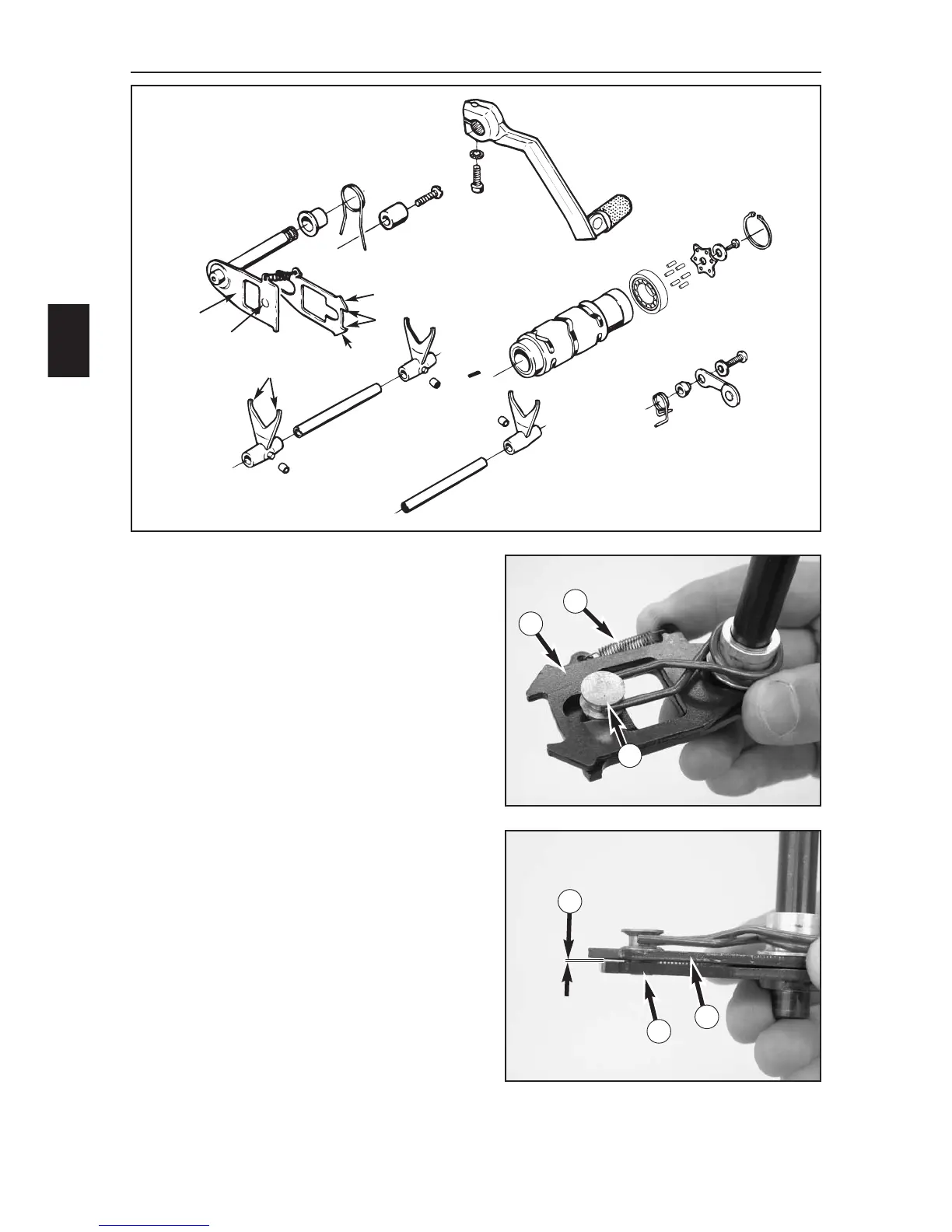

– Mount the shift rail (6) on the shift quadrant (7) and

attach the spring (8).

–Slide the bushing (9) and the return spring (10) with

the offset facing the shift quadrant, attach the return

spring to the guide bolt.

– Check the clearance (E) between the shift rail (6) and

shift quadrant (7). It should lie between 0.40 and 0.80

mm.

1

1

1

2

3

5

4

4

4

6

7

9

10

D

B

C

C

5

A

6

D

8

E

6

7

Loading...

Loading...