Mat No.: 669756 / Revised: 05.04.2018 E

17

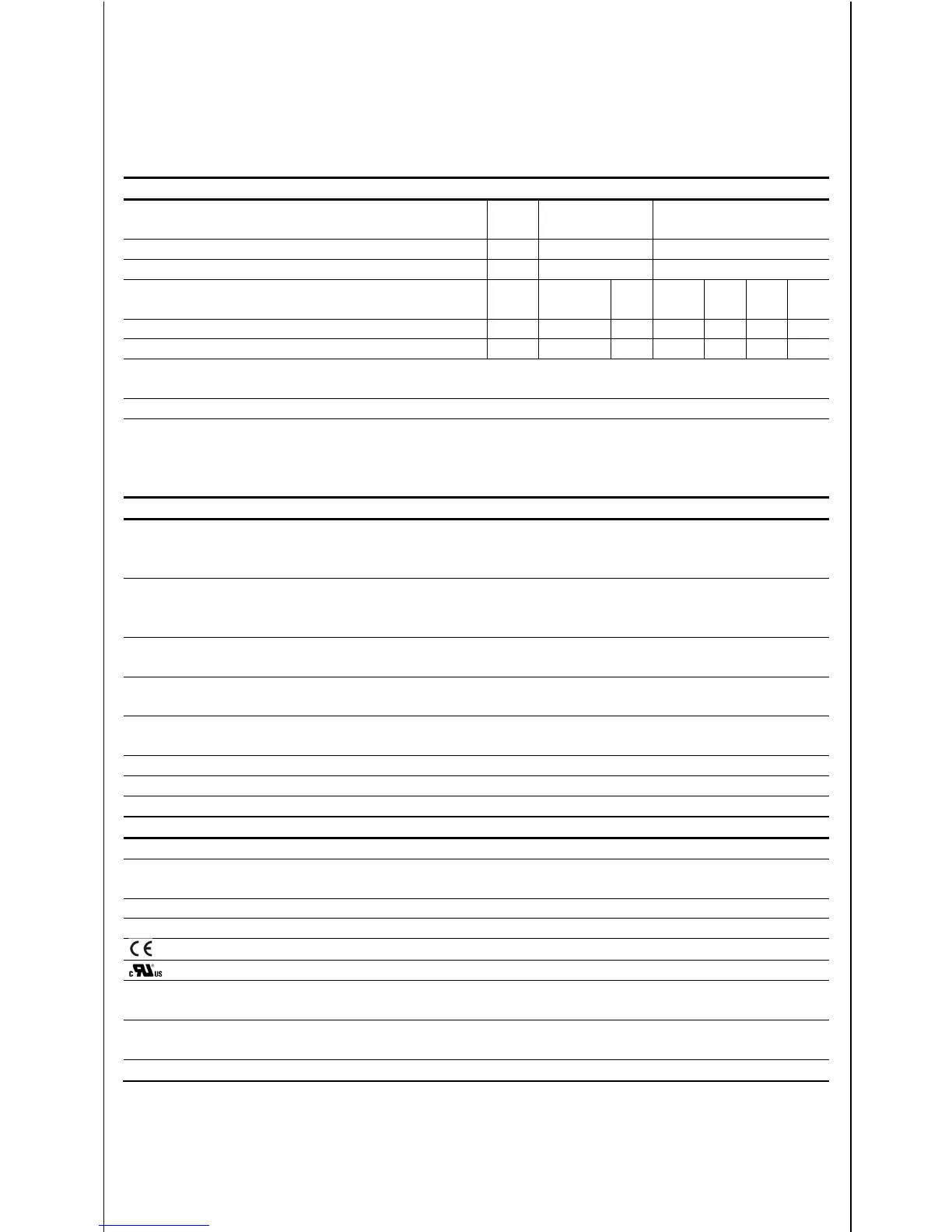

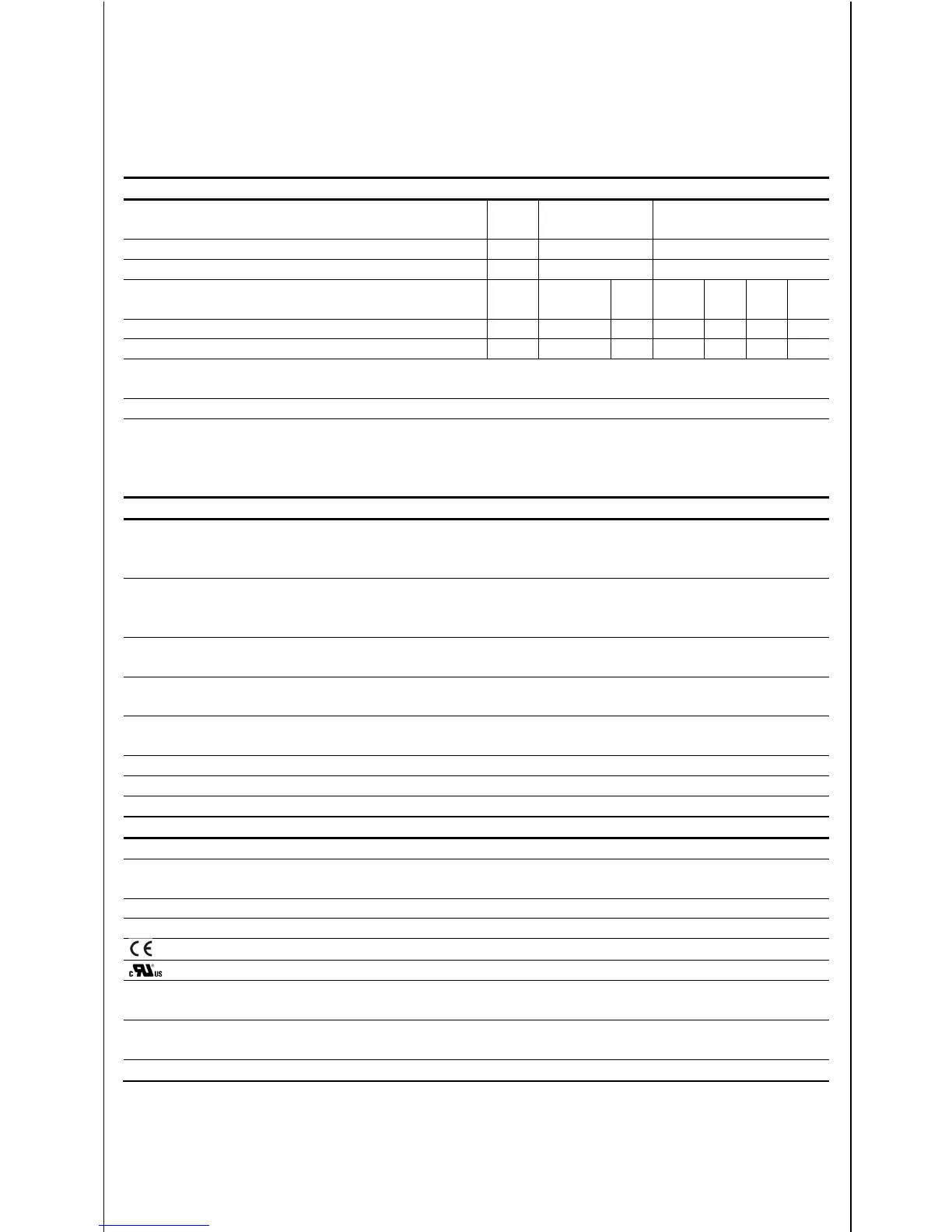

11 Technical specifications

11.1 EDS 3000 WITH CERAMIC SENSOR CELL;

ABSOLUTE AND RELATIVE PRESSURE UP TO 16 BAR

Input data

Measuring ranges for

ceramic sensor at absolute pressure

bar 1 2.5

Overload pressures bar 3 8

Burst pressure bar 5 12

Measuring ranges for

ceramic sensor at relative pressure

bar -1 .. 1 1 2,5 6 10 16

Overload ranges bar 3 3 8 18 30 48

Burst pressure bar 5 5 12 30 50 80

Mechanical connection G1/4 A ISO1179-2, male (DIN 3852)

Port DIN 3852-G1/4

Tightening torque, recommended 20 Nm

Parts in contact with fluid Mech. connection: Stainless steel

Sensor cell: Ceramic

Seal: FPM / EPDM

(according to ordering details)

Output data

Switching outputs 1 or 2 PNP transistor outputs

Switching current: max. 1.2 A per output

Switching cycles: > 100 million

Analogue output, permitted load resistance Selectable:

0 .. 10 V; Load resistance min. 1 kΩ

4 .. 20 mA; Load resistance max. 500 Ω

Accuracy acc. to DIN 16086,

Terminal based

≤ ± 0.5 % FS typ.

≤ ± 1 % FS max.

Temperature compensation, zero point ≤ ± 0.015 % FS / °C typ.

≤ ± 0.025 % FS / °C max.

Temperature compensation, span ≤ ± 0.015 % FS / °C typ.

≤ ± 0.025 % FS / °C max.

Repeatability ≤ ± 0.25 % FS max.

Reaction time < 10 ms

Long-term drift ≤ ± 0.3 % FS typ./ year

Environmental conditions

Compensated temperature range -10 .. + 70 °C

Operating temperature range -25 .. + 80 °C

(-25 .. 60 °C acc.to. UL-Spez.)

Storage temperature range -40 .. + 80 °C

Fluid temperature range -25 .. + 80 °C

mark

EN 61000-6-1, 2, 3, 4

-mark

Loading...

Loading...