HyPrecision Predictive waterjet pump Operator Manual 810120 113

5 – Preventive maintenance

Preventive maintenance

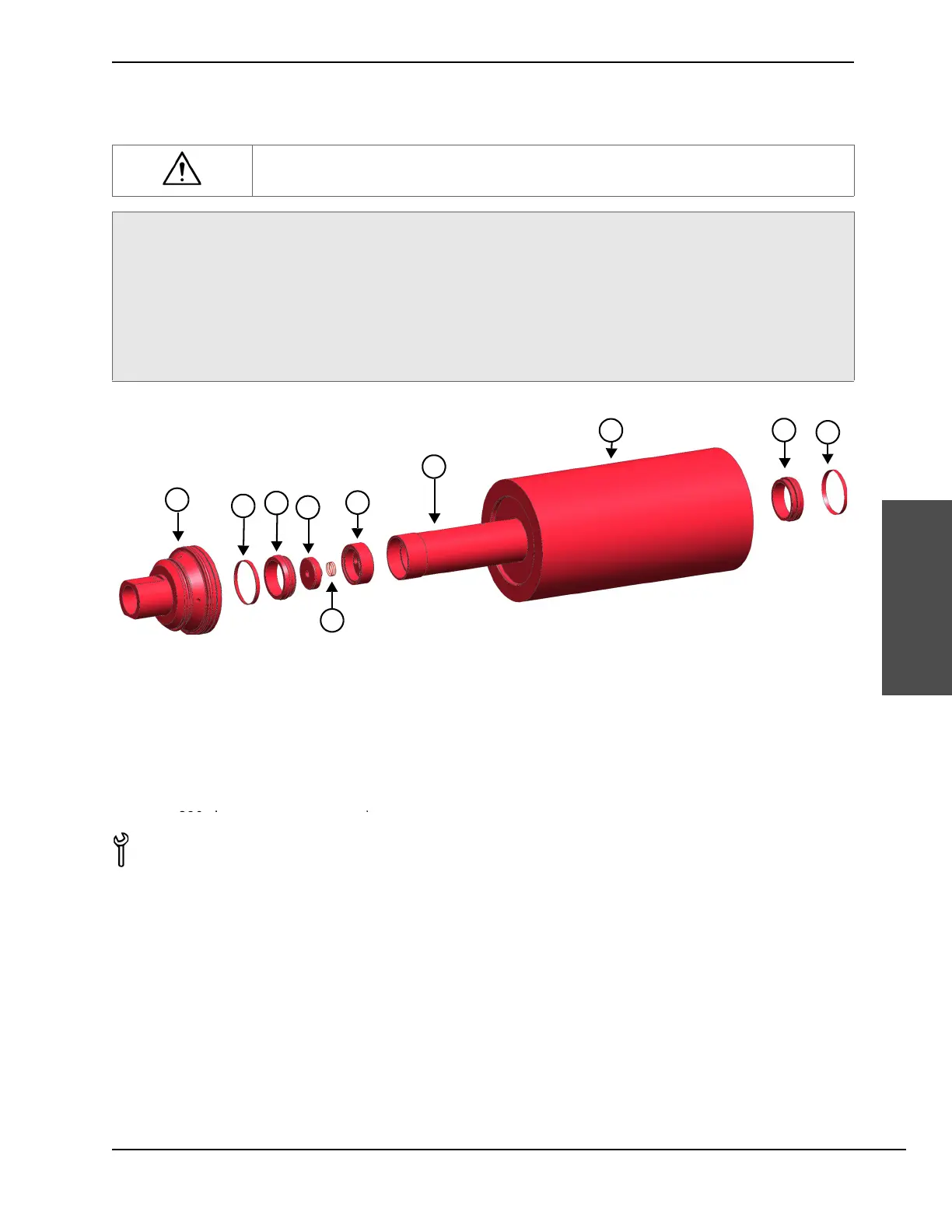

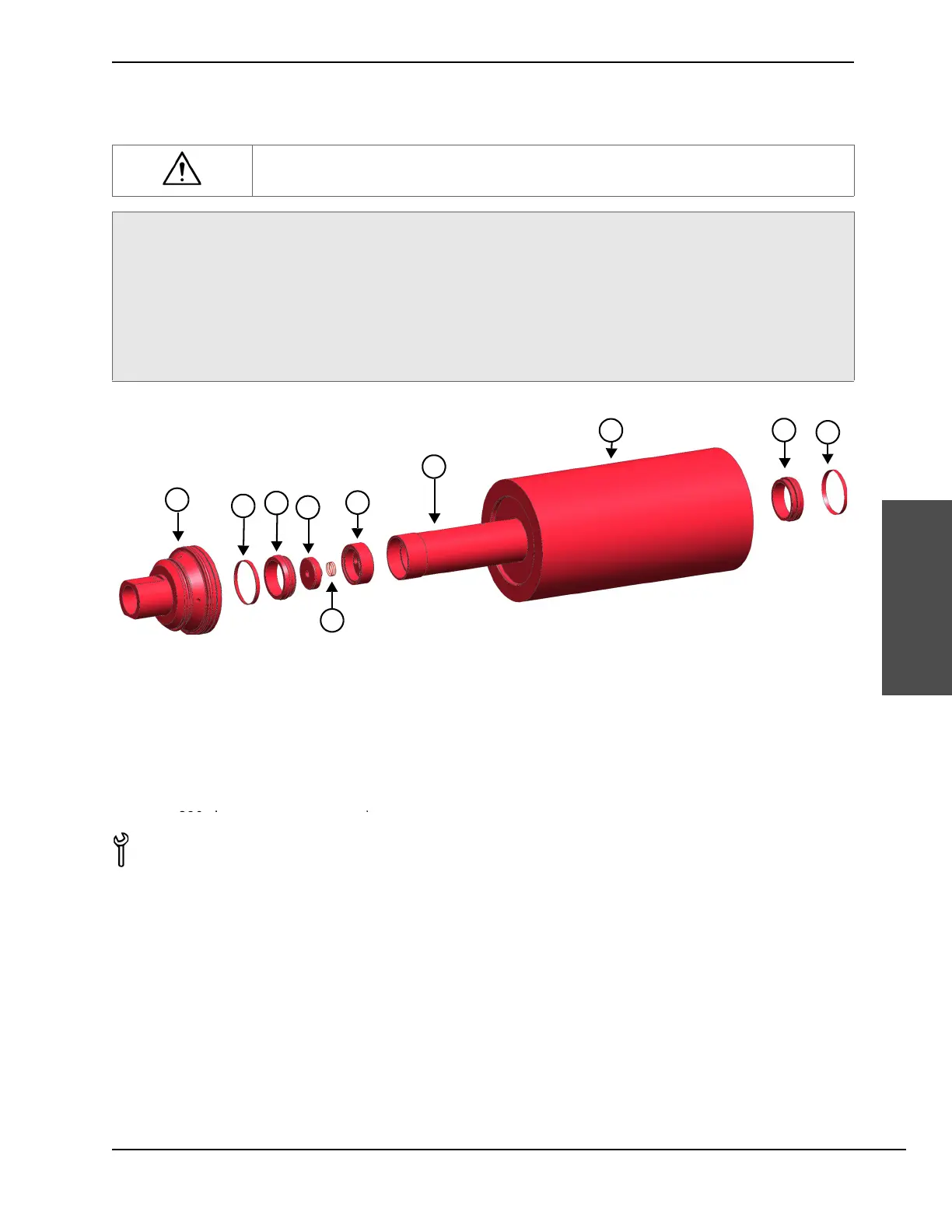

Install the high-pressure hoops, the high-pressure water seals, the high-pressure cylinders, and the

check valves

Parts, tools, and materials

Do not put grease or lubricant on the check valve face or in the cylinder bore. These components

are designed for dry contact.

Repair the high-pressure cylinders and the check valves every 500 hours.

Repair the high-pressure hoops and the high-pressure water seals every 500 hours.

Replace the check valves every 2,000 hours.

Replace the high-pressure cylinders:

• every 3,000 hours

• if the cylinder is chipped or cracked

Install a new plunger bearing when replacing the high-pressure cylinder.

1

1-11523 Check valve assembly

2

1-11018 High-pressure hoop

3

1-11024 High-pressure water seal

4

1-14792 Low-pressure poppet

or

1-11526 Low-pressure poppet

390 L i

6

1-11520 Low-pressure poppet basket

7

1-11521 Spacer tube

8

1-11522 High-pressure cylinder

1-17437 HyPrecision premium high-pressure seal

repair kit

1-15565 HyPrecision poppet repair kit

(for HyPrecision P-15/P-30/P-50 pumps)

or

1-15568 HyPrecision poppet repair kit

(for HyPrecision P-50S/P-60S/P-75S pumps)

1-11523 Check valve assembly

1-11520 Low-pressure poppet basket

1-11521 Spacer tube

1-11522 High-pressure cylinder

High-pressure antiseize lubricant such as Blue

Goop or PURE Goop

Seal installation tools (refer to page 72)

Rubber mallet

Loading...

Loading...