76 HyPrecision Predictive waterjet pump Operator Manual 810120

5 – Preventive maintenance

Preventive maintenance

General

Examine and clean the equipment

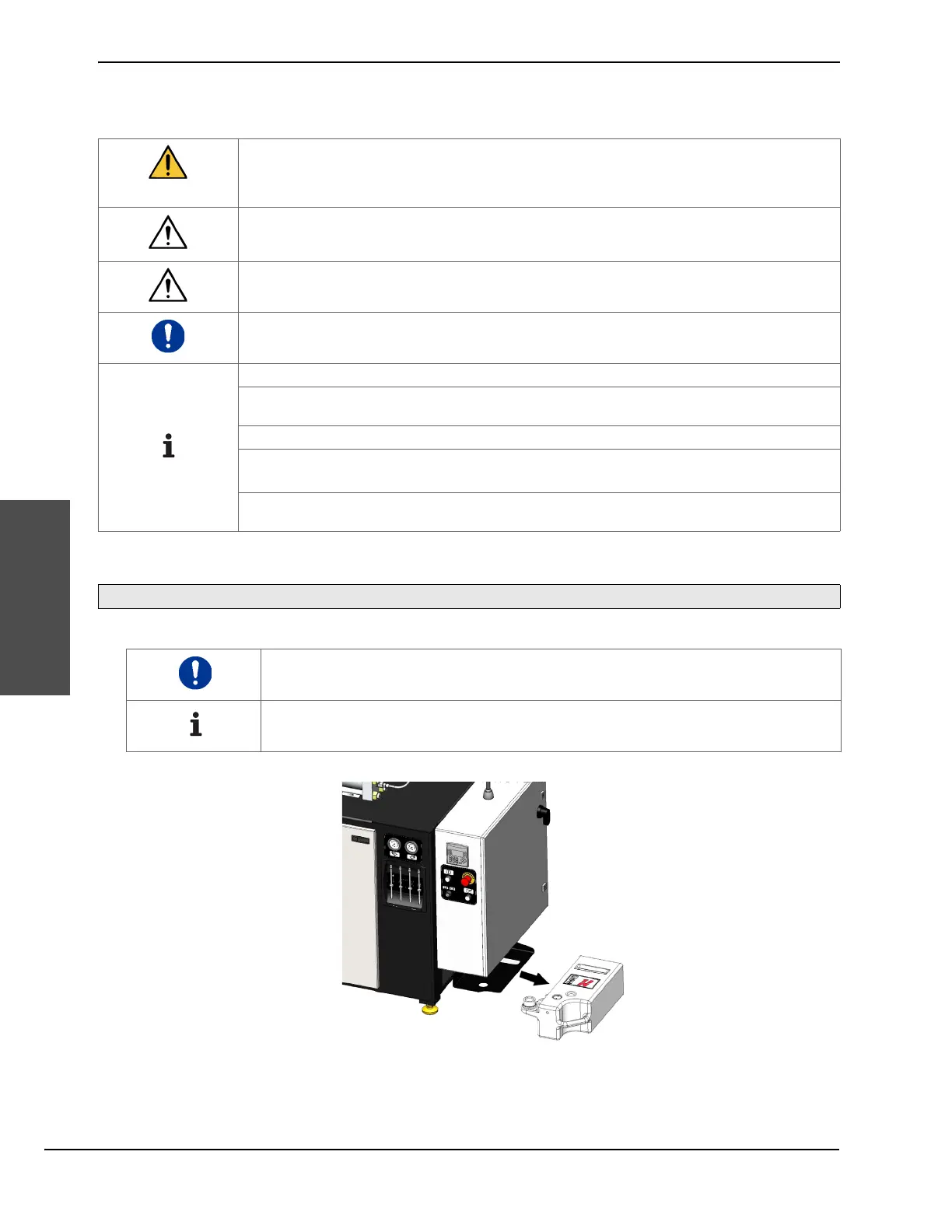

1. Check the dirty water container.

Empty the container, if necessary

WARNING

Repair or replace parts identified in the preventive maintenance schedule or if the parts show

deterioration, corrosion, or damage.

Hydraulic, water, and electrical connections can become loose during shipping and normal

operation. We recommend examining all connections at installation and during regular

maintenance.

Identify the source of a leak and correct the problem. Refer to Leaks on page 163.

A leak can cause damage to the water fittings.

When replacing wiring, use only the same size, type, and color as the original wiring.

Coordinate maintenance and repairs with facility and safety staff.

Keep the work area clean and dry. Clean fluid spills immediately. Use catch basins under areas

where water or hydraulic fluid can spill during maintenance or repair procedures.

Keep spare parts and repair kits available.

Some referenced parts are included in kits. Refer to the

Parts lists section, which starts on

page 137

for information.

Keep the work area clean and dry. Clean fluid spills immediately. Use catch basins under areas

where water or hydraulic fluid can spill during maintenance or repair procedures.

Do this every work shift.

Refer to local regulations regarding waste water.

Environmental rules can apply to disposal.

Water in the container could have oil in it.

Loading...

Loading...