OPERATION

HySpeed HT2000LHF Instruction Manual 4-27

Shield Arc Approx.

Material

Plasma Gas Flow Rate %

Gas (Air) Torch-to-work Initial Torch Voltage Motion

Thickness Preflow Cutflow Pressure Distance Piercing Height Setting Travel Speed Delay Time

(inches) (mm) (Air %) (Air %) (psi) (inches) (mm) (inches) (mm) (volts) (ipm) (mm/min.) (sec)

Shield Arc Approx.

Material

Plasma Gas Flow Rate %

Gas (Air) Torch-to-work Initial Torch Voltage Motion

Thickness Preflow Cutflow Pressure Distance Piercing Height Setting Travel Speed Delay Time

(inches) (mm) (Air %) (Air %) (psi) (inches) (mm) (inches) (mm) (volts) (ipm) (mm/min.) (sec)

1/8 3 48 39 60 3/32 2.5 3/16 5 135 110 2800

3/16 5 (55.3 (44.9 (270 1/8 3 1/4 6 140 90 2290 0.5

1/4 6 SCFH) SCFH) SCFH) 1/8 3 1/4 6 145 70 1780 0.5

3/8 10 1/8 3 1/4 6 145 50 1270 0.5

1/2 12 1/8 3 150 40 1010

5/8 15 .157 4 155 30 760

3/4 20 3/16 5 160 25 635

Aluminum

100 amps • Air Plasma / Air Shield

This gas combination gives good cut speed, low dross levels and is very economical.

Notes: Set plasma gas inlet pressure to 90 psi (6.2 bar)

Set shield gas inlet pressure to 90 psi (6.2 bar)

Production cutting above 3/8" (10 mm) not recommended

Above Water

1/8 3 48 39 70 5/64 2 5/32 4 135 100 2650

3/16 5 (55.3 (44.9 (280 1/8 3 1/4 6 140 80 2050 0.5

1/4 6 SCFH) SCFH) SCFH) 1/8 3 1/4 6 145 60 1510 0.5

3/8 10 1/8 3 1/4 6 150 40 1000 0.5

1/2 12 1/8 3 155 30 750

3" Under Water

020448

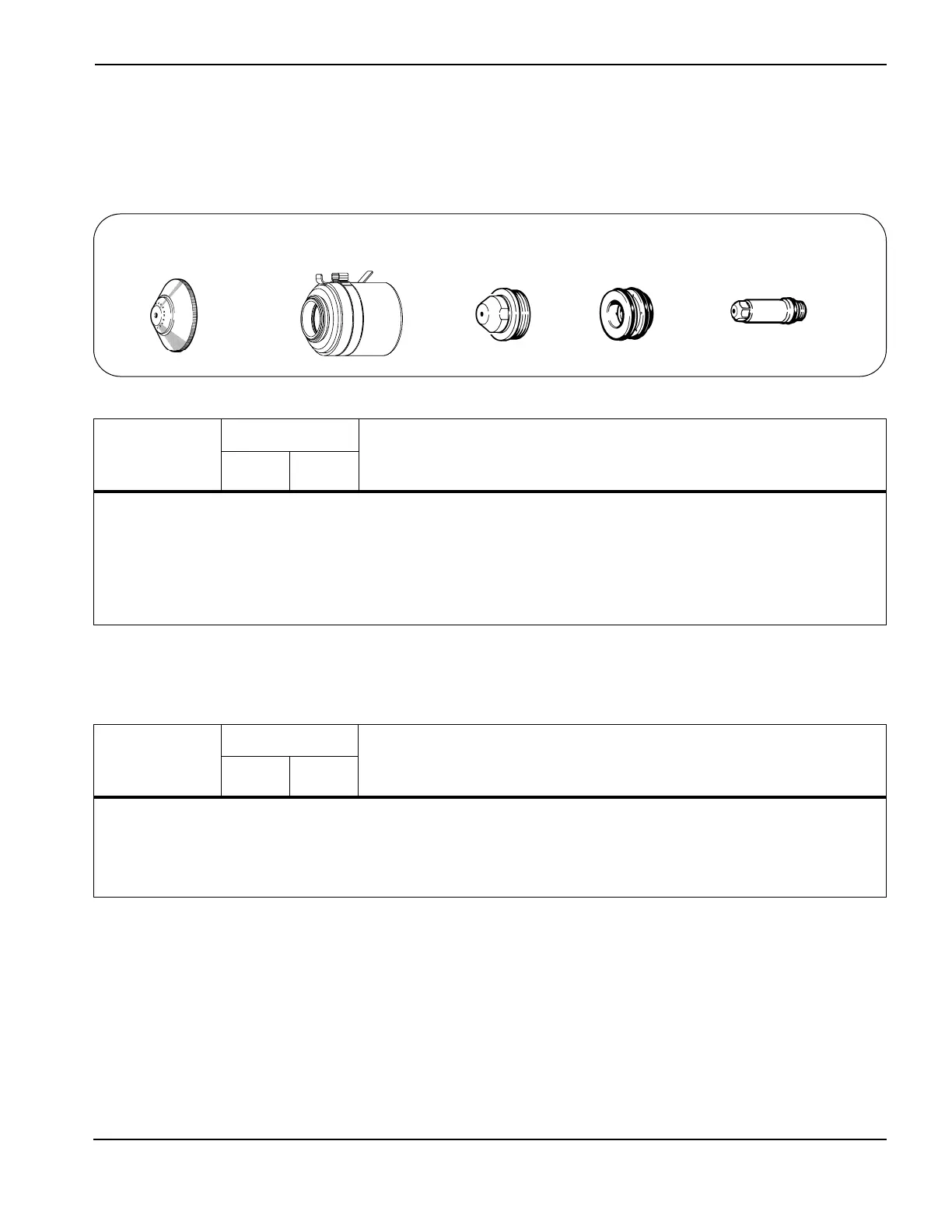

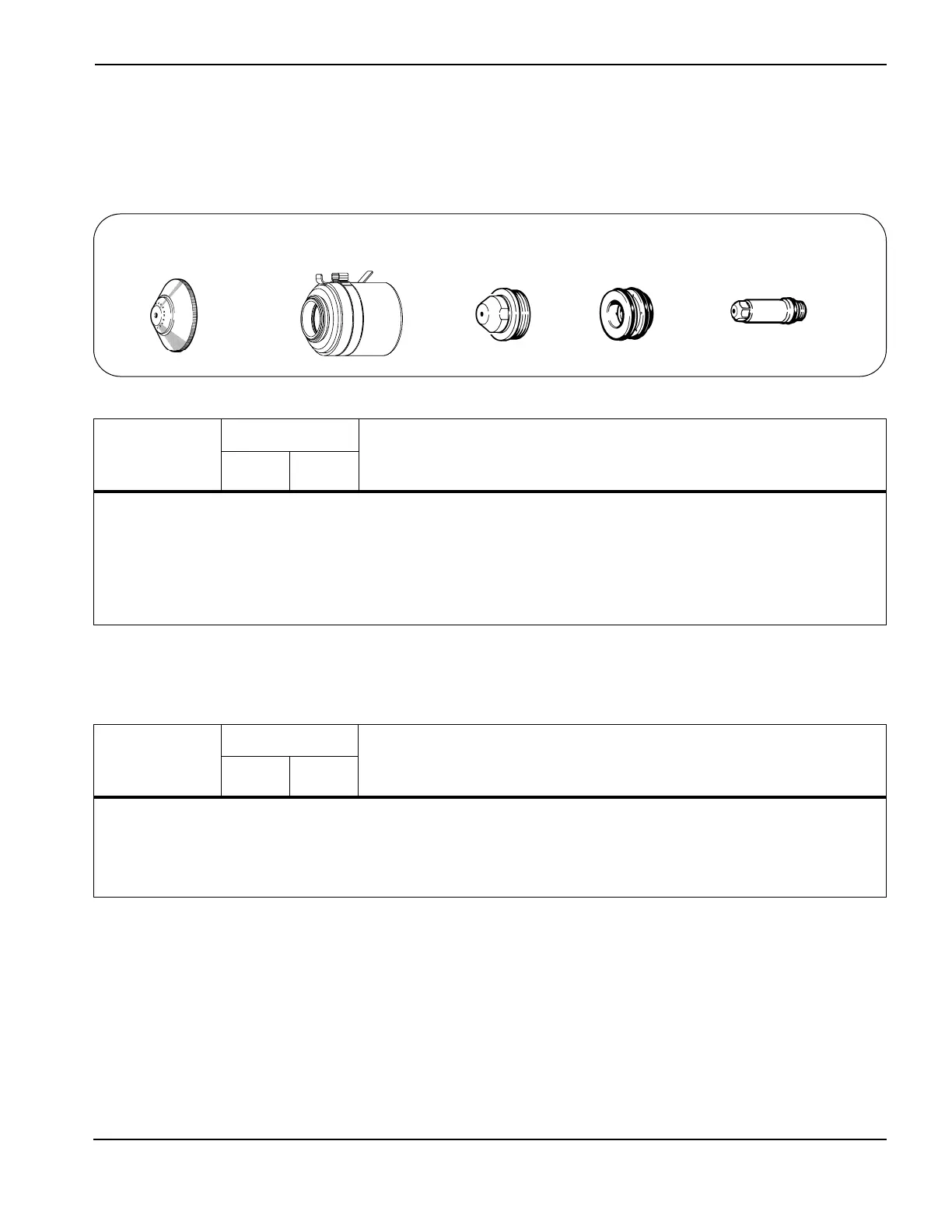

Shield

120837

Retaining cap

020611

Nozzle

020607

Swirl ring

120547

Electrode

7

Loading...

Loading...