1900 SRM 964 Relief Valve Adjustment

Relief Valve Adjustment

RELIEF VALVE PRESSURE CHECK

WARNING

DO NOT make rep

airs or adjustments unless

you have been

properly trained and authorized

to do so. Impr

oper repairs and adjustments

can create da

ngerous operating conditions.

DO NOT operat

e a lift truck that needs re-

pair. Report

the problem to your supervisor

immediatel

y. If repairs are necessary, turn the

key switch t

o the OFF position, attach a DO

NOT OPERATE

tagtothecontrolhandle,and

disconnect

the battery.

Always wear

the proper protective equipment

including e

ye protection and petroleum resis-

tant glove

s when servicing hydraulic compo-

nents. Tho

roughly wash oil from exposed ar-

eas of skin

as soon as possible.

Completel

y lower forks to relieve hydraulic

pressure b

efore disassembling any part of the

lift pump

or disconnecting any hoses.

The hydra

ulic oil is hot at normal operating

temperat

ures. Be careful when draining the

oil.

Never che

ck for leaks by putting hands on

hydrauli

c lines or components under pressure.

Hydrauli

c oil under pressure can be injected

into the

skin.

CAUTION

DO NOT OVERFILL RESERVOIR. Oil will leak

from the breather/filler cap during operation if

reservoir is over filled.

NOTE: Check the hydraulic oil level in the reservoir

when oil is at room temperature. Remove breather

cap and add recommended hydraulic oil to proper

level, as required. See Hydraulic Reservoir, Table 1.

1. Operate lift truck until hydraulic oil reaches op-

erating temperature [43 to 49

C(110to120F)].

2. Lower the forks completely to relieve pressure

from hydraulic circuit.

3. Turn the key switch to the OFF position and dis-

connect the battery.

4. Block load wheels to prevent lift truck from

moving. Refer to the section Periodic Mainte-

nance 8000 SRM 919, Periodic Maintenance

8000 SRM 1032, Periodic Maintenance 8000

SRM 1368, or Periodic Maintenance 8000

SRM 1298 - How to Put A Lift Truck on Blocks.

5. Remove the drive unit compartment covers. See

Drive Unit Compartment Covers.

6. Discharge the capacitor. See Special Precau-

tions.

7. Clean any buildup of dirt from around the lift

pump and motor assembly.

CAUTION

Protect the hydraulic system from dirt and

contaminants when servicing the hydraulic

system.

8. Disconnect the hydraulic hose at the pump.

9. Install a tee fitting and a pressure gauge of at

least 24.8 MPa (3600 psi).

10. Verify the oil is at an operating temperature of

43 to 49

C(110to120F).

11. Raise the forks completely and continue to hold

the lift button. Read the pressure gauge while

the pump is in relief. See Table 2 for correct pres-

sures.

NOTE: Thepumpwillstopafterashortperiodof

time. Release the lower button then press and hold

again to continue.

12. If the relief pressure is incorrect refer to Adjust

Relief Valve Pressure.

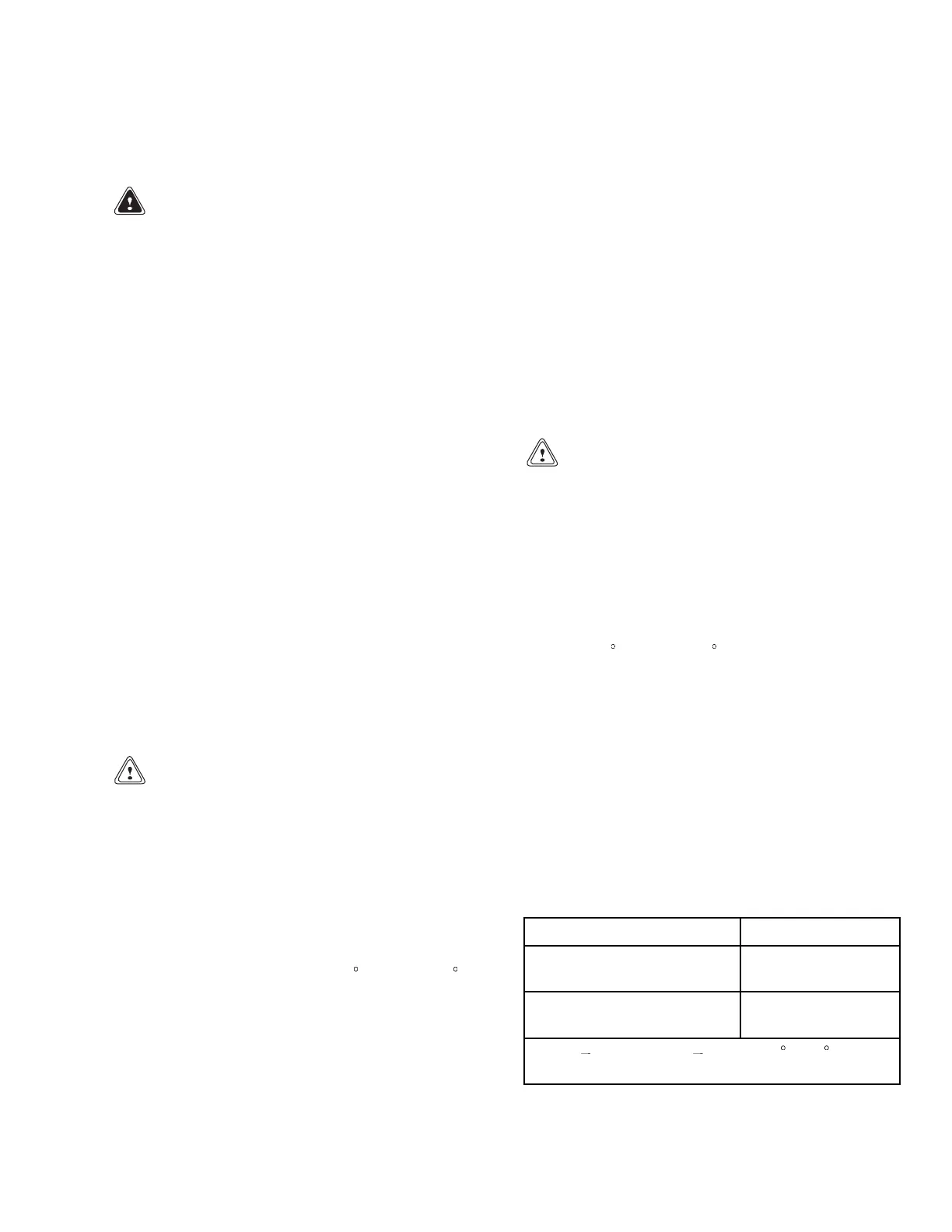

Table 2. Relief Valve Settings

Model Relief S

etting*

B60Z, B60Z

AC

, C60Z,

C60Z

AC

,andW60Z

18.96 MPa

(2750 psi)

B80Z, B80Z

AC

, C80Z,

C80Z

AC

, W65Z, and W80Z

24.2 MPa

(3500 psi)

*+0.6 0.0 MPa (+87 0psi)@21C(70F)

Oil Temperature

23

Loading...

Loading...