1900 SRM 964 Special Precautions

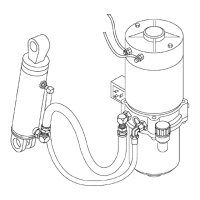

Legend for Figure 3

1. SOCKET-HEAD S

CREW

2. LOCKWASHER

3. MOUNTING BRACKET

4. LOCKWASHER

5. CAPSCREW

6. LOCKWASHER

7. CAPSCREW

8. LIFT PUMP AND MOTOR ASSEMBLY

9. ADAPTER

10. FITTING

11. TUBE ASSEMBLY

12. ADAPTER

13. ELBOW FITTING

14. HOSE ASSEMBLY

15. ELBOW FITTING

16. LIFT CYLINDER ASSEMBLY

CLEAN

Adhere to the following precautionary steps to en-

sure that the hydraulic system remains clean.

1. Clean the reservoir and pump area to prevent

contaminants from entering the hydraulic sys-

tem.

2. Clean (flush) the entire system when a failure is

encountered to make sure all paint, metal chips,

welding shot, and debris are removed.

3. Filter each change of oil to prevent the introduc-

tion of contaminants into the system.

4. Provide continuous protection from airborne con-

tamination by keeping the breather cap clean

and serviceable.

SOUND LEVEL

Hydraulic system noise may be caused by both im-

properly selected oil and loose or damaged system

components.

• Cavitation - Can be caused by high fluid viscos-

ity, cold fluid temperatures, or a restriction in the

inlet screen or inlet tubing. At startup, low temper-

atures can cause pump noises due to cavitation.

• Aerated Hydraulic Oil - Results in system noise

that is similar to cavitation. Aerated oil is caused

by the ingestion of air through the joints of the in-

let lines and high-velocity discharge lines. Aera-

tion can also be caused by oil discharging above the

fluid level in the hydraulic reservoir. Aerated hy-

draulic oil occurs when air does not have sufficient

time to escape from the fluid while in the reservoir

before recycling through the system.

Special Precautions

WARNING

The capaci

tor in the transistor controller can

hold an ele

ctrical charge after the battery is

disconnec

ted. To prevent an electrical shock

and person

al injury, discharge the capacitor

before ins

pecting or repairing any component

in the dri

ve unit compartment. Wear safety

glasses.

Make certain that the battery has

been disc

onnected.

CAUTION

To avoid controller damage, always disconnect

the battery, discharge the capacitor, and never

put power to the controller while any power

wires are disconnected. Never short any con-

troller terminal or motor terminal to the bat-

tery. Make sure to use proper procedure when

servicing the controller.

1. Verify that the key switch is in the OFF position

and the battery connector is completely discon-

nected.

2. Discharge the capacitors in the controllers by

connecting a 200-ohm, 2-watt resistor across

the controller’s B+ and B

terminals. DO NOT

short across the motor controller terminals

withascrewdriverorjumperwire. Removethe

200-ohm, 2-watt resistor before reconnecting the

battery. See Figure 4 or Figure 5.

5

Loading...

Loading...