Chapter 3 Operation

POWER CON

PCON-CB/LC

80

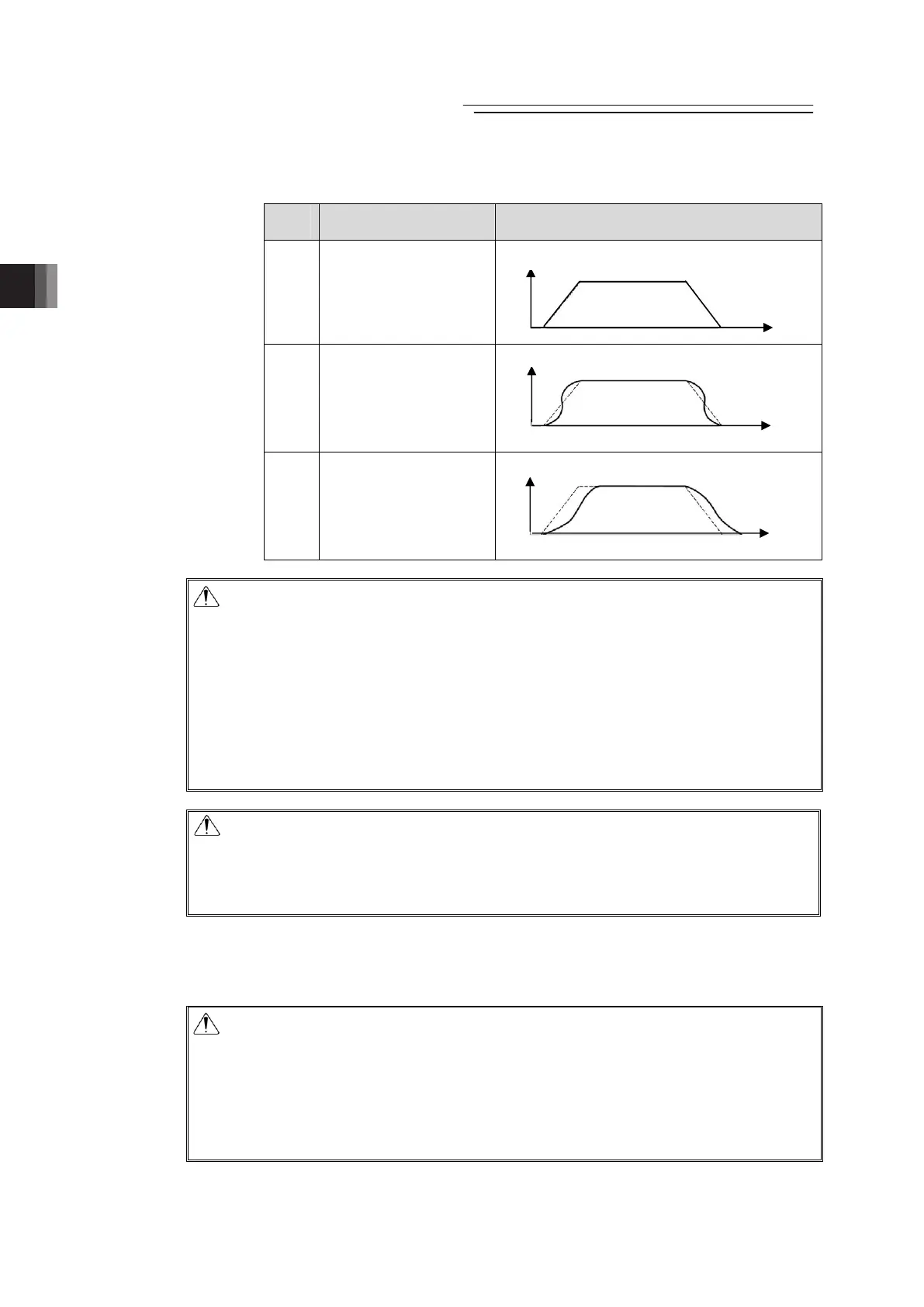

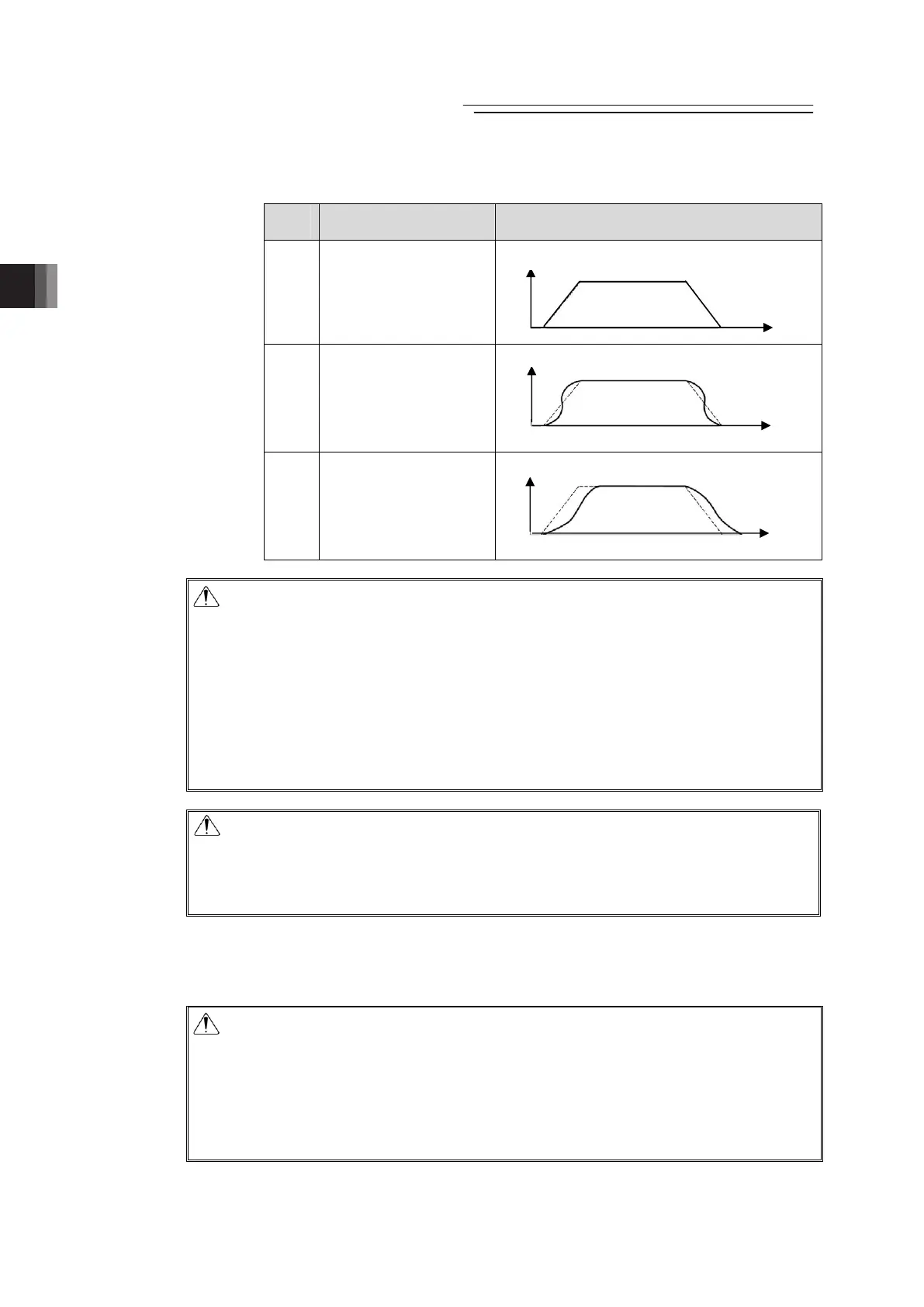

11) Acceleration / deceleration mode ······Select a proper acceleration/deceleration pattern

depending on the load.

Set

Value

Acceleration/

Deceleration Pattern

Operation

0 Trapezoid

1 S-motion

(Refer to Caution at

S-shaped Motion)

Set the S-motion rate with parameter No.56.

2 First-Order

Lag Filter

Set the delay time constant with parameter No.55.

Caution at S-shaped Motion:

1) Since it requires a speed change during the operation, even if having the position

command or direct command that S-shaped motion is set while the actuator is moving,

S-shaped motion control cannot be performed and will be the trapezoid control.

Make sure to make a command while the actuator is stopped.

2) S-shaped motion control is invalid in the index mode of the rotary actuator. It will be the

trapezoid control even if S-shaped acceleration/deceleration control is indicated.

3) Do not use S-shaped acceleration/deceleration control if the setting of the acceleration

time or the deceleration time exceeds 2 seconds. It will not provide the right operation.

4) Do not pause on the move during acceleration or deceleration. It will change the speed

(acceleration) and may cause a danger.

Caution on First-Order Lag Filter :

Even if the position command or direct value command is conducted with first-order lag

filter being set while the actuator is operated in order to have a speed change during an

operation, it will not make first-order lag filter control, but will make trapezoid control.

Make sure to issue the command while the actuator is stopped.

12) Incremental ··········· Set to 1 for pitch feed (relative movement = incremental feed).

The value set for the position in 1) indicates the pitch feed distance.

With the value set to 0, positioning is defined to the position in 1)

based on the absolute coordinate system.

Caution: In the pitch feed, do not perform a command with a pitch smaller than the

minimum encoder resolution (lead/encoder pulse number) or that less than

positioning accuracy repeatability.

There would be no deviation to occur even with the command because it is

an operation command to the same position as the positioning complete

condition, but the positioning control cannot be performed properly.

When solenoid valve mode 2 is selected, set this to 0. Setting this to 1 causes

the position data error to occur.

Time

Velocity

Time

Velocity

Time

Velocity

Loading...

Loading...