19 MAN-071

13 - CHOICE OF THE BEST SPROCKET RATIO

The life of an engine depends upon many factors but most of all upon the speed at

which the engine is operated. If an engine is normally operated at speeds higher than

what recommended by the manufacturer, the wears and stress of the various

components (con-rods, roller cages, bearings etc.) will be such as to drastically reduce

the life of the engine itself. It is therefore extremely important that the user respects the

operating limits imposed by the manufacturer.

The operating limit for the NORSWIFT engine is 12.500 RPM.

ATTENTION:

Never exceed the above limit. No obligation of IAME exists in case the above limit is

exceed.

In case the user wishes to optimize on the track the sprocket ratio in order to achieve the

best possible performance, without abusing the engine, follow the under shown

recommendations.

The engines are supplied with a 11 teeth sprocket (pitch: 7.775mm), and you can also

use 10 teeth sprocket.

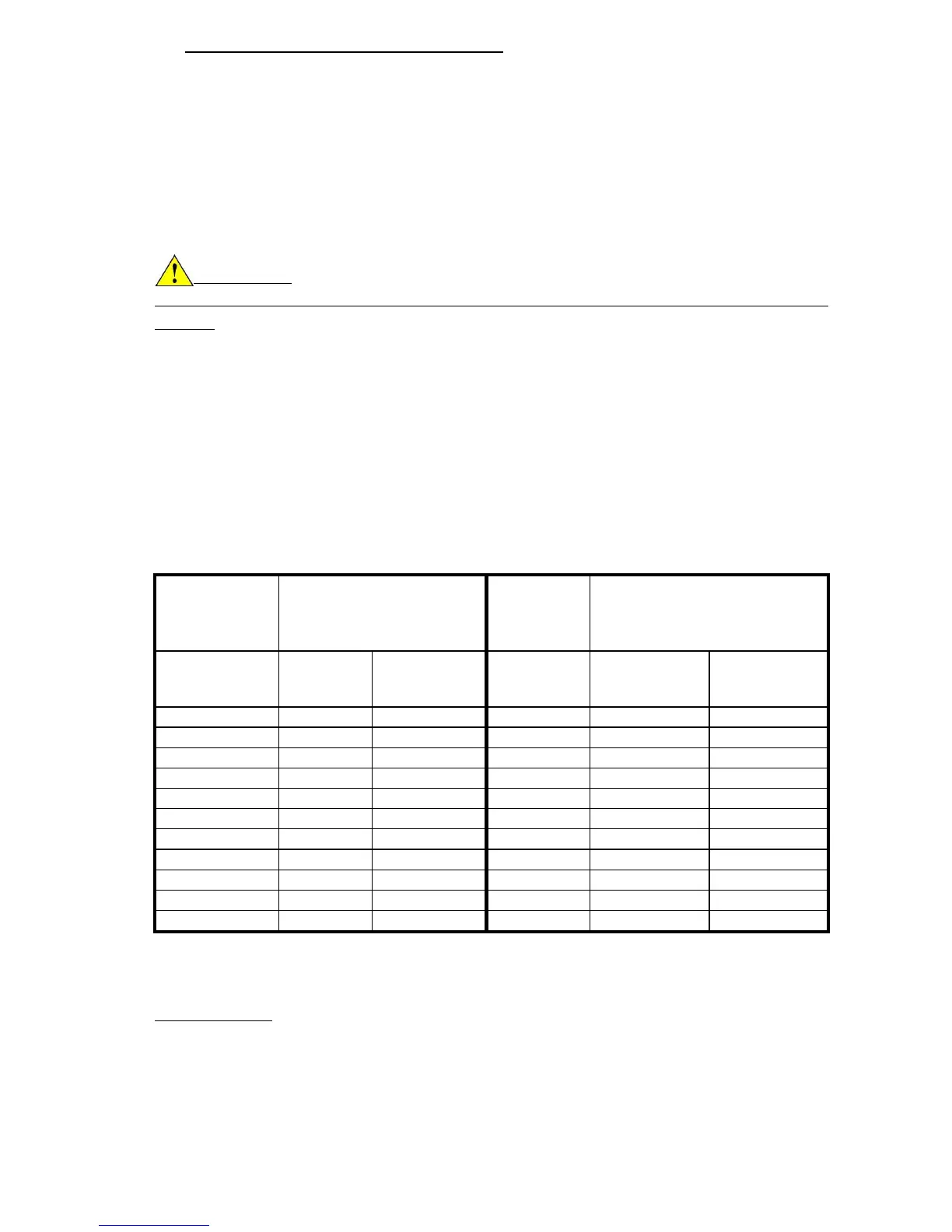

Table 1 shows the various ratios between the sprocket on the axle and the engine

sprocket given the different axle sprockets.

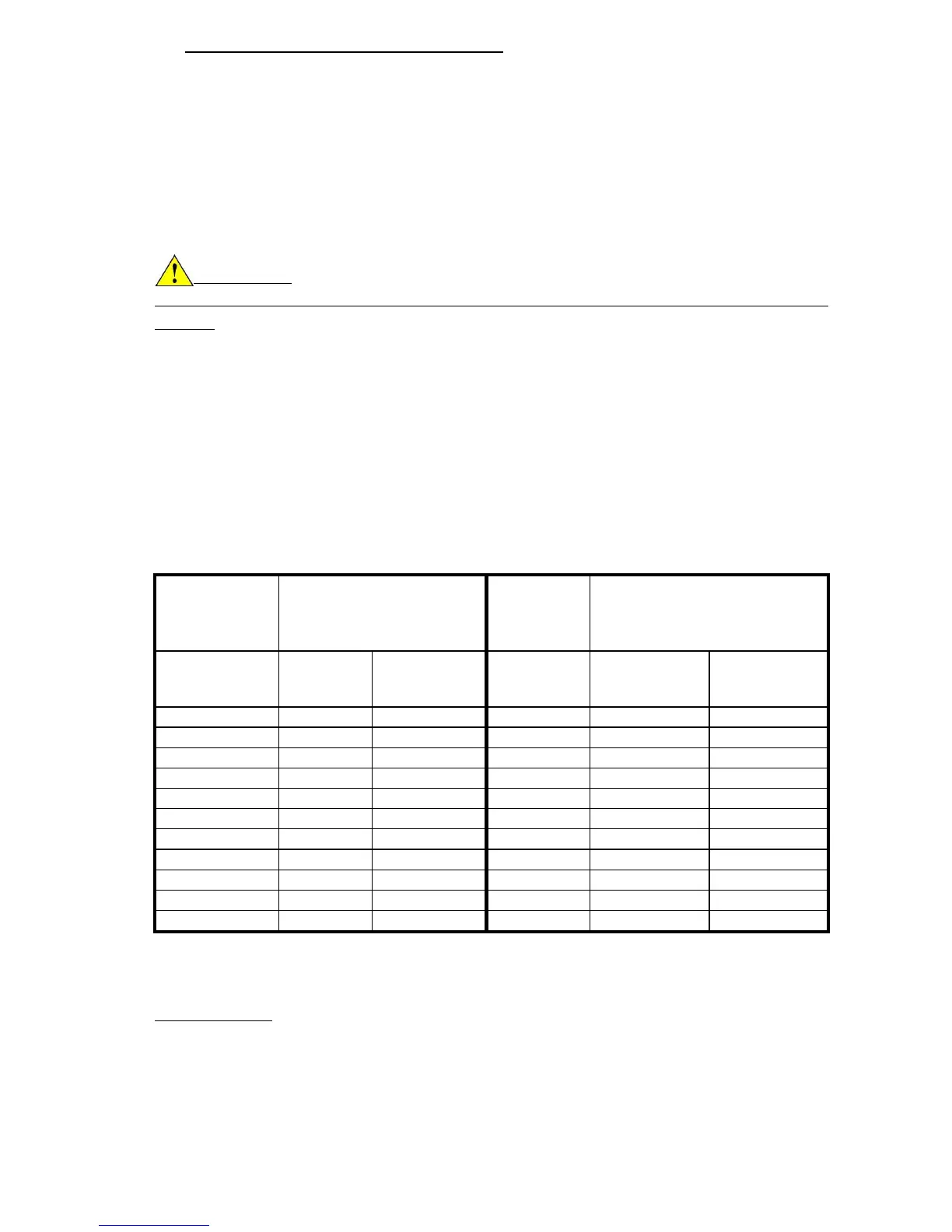

For the operation limit of 12.500 RPM the following table (tab. 2) has been prepared

SUGGESTION:

During the track tests we recommend use of a tachometer recording the max

obtained engine RPM.

Use spark plug caps with a resistance of 5KΩ to avoid eventual interferences

between the engine ignition and the tachometer and/or telemetry.

Loading...

Loading...