Additional LP Connection Requirements

1. Have a licensed LP gas dealer make all connections at stor-

age tank and check all connections from tank to furnace.

2. If copper tubing is used, it MUST complywith limitation set in

National Fuel Gas Code or CGA codes.

3. Two-stage regulation of LP gas is recommended.

LP Conversion

An accessory kit shall be used to convert to propane gas use, see

the furnace rating plate for the LP conversion accessory kit part

number.

Do NOT allow minimum gas supply pressure to vary down-

ward. Doing so will decrease input to furnace. Refer to

Table 7, Table 8, Table 9, Table 10 and Table 11 for nor-

mal gas supply and manifold pressures.

Gas SupplyPressure

Gas supply pressure should be within minimum and maximum val-

ues listed on rating plate. Pressures are usually set by gas suppli-

ers.

Manifold Gas Pressure Adjustment

NOTE: Make adjustment to manifold pressure with burners oper-

ating.

FIRE, EXPLOSION, UNIT DAMAGE HAZARD.

Failure to follow this warning can result in

death, property damage and/or personal

injury.

An LP conversion accessory kit is required

when operating the furnace with LP gas.

AlternateBTUHInput Ratings(USA Only)

The input rating of these furnaces can be changed from the stan-

dard input rating to the alternate input rating shown in Table 7, by

changing the main burner orifices. Changing of burner orifices

MUST be done by a qualified service technician. See section on

changing orifices or following page.

I

Alternate Input Ratings, USA ONLY.

BTUH

Standard

Rating

50,000

75,000

100,000

125,000

BTUH

Alternate

Rating

40,000

60,000

80,000

100,000

Natural

Gas

Orifice*

#44

#44

#44

#44

LP

Gas

Orifice**

#55

#55

#55

#55

* See Table 10 for High Altitude.

** See Table 11 for High Altitude

SupplyPressure

ELECTRICAL SHOCK HAZARD.

Failure to do so could result in death or personal

injury.

Turn OFF power to furnace before changing speed

taps.

1,

2.

3.

4.

Remove the burner compartment door.

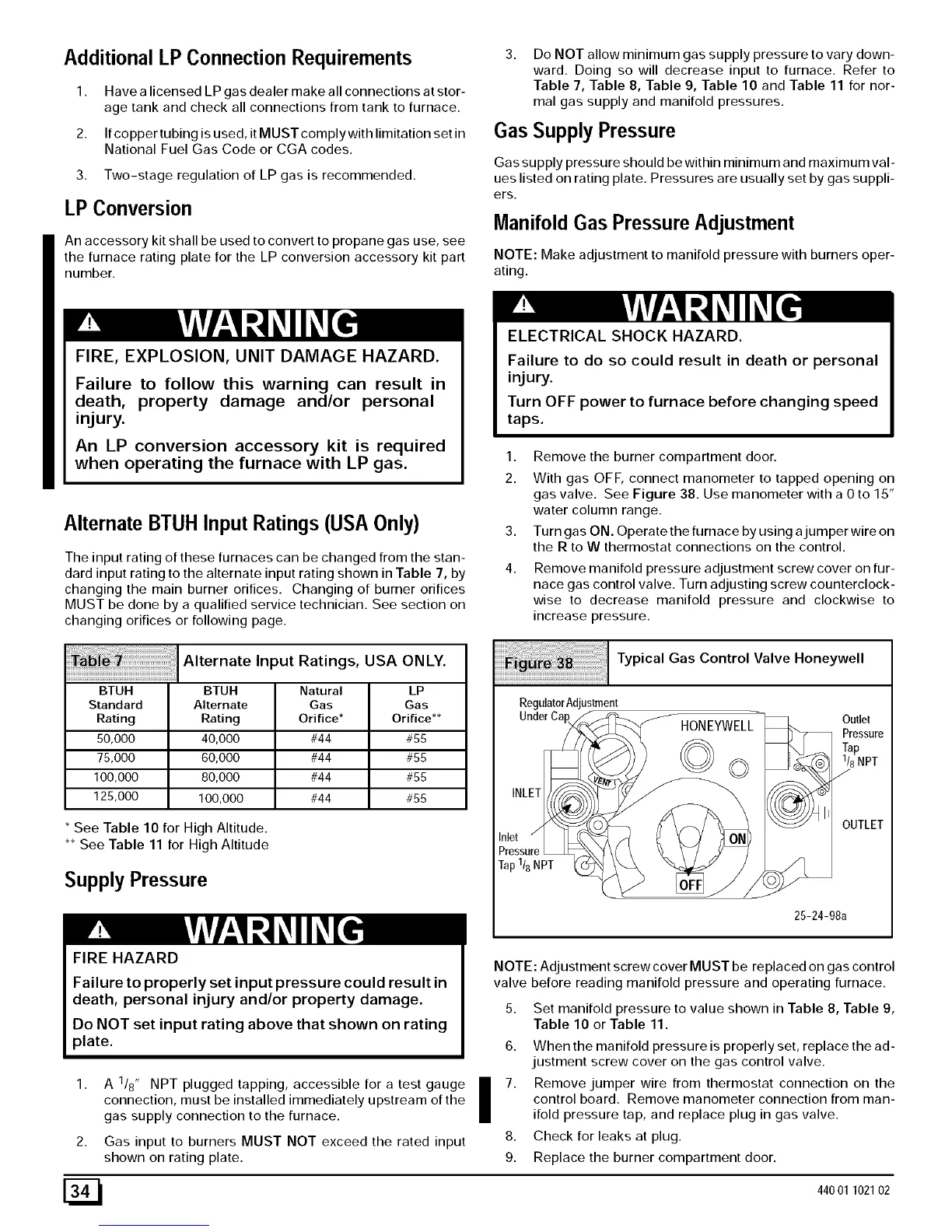

With gas OFF, connect manometer to tapped opening on

gas valve. See Figure 38. Use manometer with a 0 to 15"

water column range.

Turn gas ON. Operate the furnace by using ajumper wire on

the R to W thermostat connections on the control.

Remove manifold pressure adjustment screw cover on fur-

nace gas control valve. Turn adjusting screw counterclock-

wise to decrease manifold pressure and clockwise to

increase pressure.

iiiiiiiiiiiiil;;i;¸i¸iiil ¸i!!!;;;iiiiiiil;;iiiiiii!i!!!!!!ii!iil !;

Typical Gas Control Valve Honeywell

Regulator Adjustment

Under Ca

Inlet

Pressure

Tap1/8NPT

HONEYWELL

©o

b

Outlet

Pressure

Tap

1/8NPT

/

OUTLET

25-24-98a

FIRE HAZARD

Failure to properly set input pressure could result in

death, personal injury and/or property damage.

Do NOT set input rating above that shown on rating

plate.

1,

2,

A 1/8" NPT plugged tapping, accessible for a test gauge II

connection, must be installed immediately upstream of the

I

gas supply connection to the furnace.

Gas input to burners MUST NOT exceed the rated input

shown on rating plate.

NOTE: Adjustment screw cover MUST be replaced on gas control

valve before reading manifold pressure and operating furnace.

5. Set manifold pressure to value shown in Table 8, Table 9,

Table 10 or Table 11.

6. When the manifold pressure is properly set, replace the ad-

justment screw cover on the gas control valve.

7. Remove jumper wire from thermostat connection on the

control board. Remove manometer connection from man-

ifold pressure tap, and replace plug in gas valve.

8. Check for leaks at plug.

9. Replace the burner compartment door.

[_1 44001 102102

Loading...

Loading...