forthe unit maximum amps stated on the rating plate. Add the full

load amps for potential field-installed accessories such as elec-

tronic air cleaners and humidifiers that would receive power from

the furnace control. The furnace control is rated for a maximum of

1.0 amps combined for EAC and HUM. Consult NEC or local

codes for proper wire and circuit sizing.

NOTE: Furnace will not have normal operation if line polarity is re-

versed. Check ALL field and control connections prior to opera-

tion.

J- Box Relocation

The j-box is installed on left side of casing. An alternate j-box

location on right side can be used.

1. Remove bag containing two hole plugs and two self tapping

screws from loose parts bag in blower compartment.

2. Remove two screws holding j-box to casing.

3. Install large hole plug from loose parts bag into the left j-box

location.

4. Clip wiretie holding j-box wires.

5. Move j-box to alternate location and attach using two self

tapping screws from bag.

6. Apply two hole plugs from bag at left j-box location.

Thermostat

Thermostat location has an important effect on the operation of the

unit. Follow instructions included with thermostat for correct

mounting and wiring.

Low voltage connections to furnace must be made on terminal

board of furnace control.

Set thermostat heat anticipator in accordance with the Technical

Support Manual.

Heat anticipator setting will need to be measured if 24VAC humidi-

fier is installed. Measure currentin series from R to W at the ther-

mostat. Be sure 24VAC humidifier is wired up to control. Allow

furnace to operate for 2 minutes before recording the AC amper-

age reading. Set anticipator on thermostat to recorded value.

Optional Equipment

All wiring from furnace to optional equipment MUST conform to lo-

cal codes or, in the absence of local codes with the latest edition of

The National Electric Code, ANSI NFPA 70 and/or The Canadian

Electric Code CSA C22.1. Install wiring in accordance with

manufacturer's instructions. The wiring MUST have a minimum

temperature rating of 105 ° C.

Humidifier/Electronic Air Cleaner

The furnace is wired for humidifier and/or electronic air cleaner

connection.

REDUCED FURNACELIFE HAZARD

Failure to follow caution instructions may result in

reduced furnace life.

Do NOT exceed 115V/1.0 amp. maximum current

load for both the EAC terminal and the HUM

terminal combined.

HUMIDIFIER- The HUM (115) is energized when the pressure

switch closes on a call for heat. The HUM is energized when

the inducer is enerqized.

ELECTRONIC AIR CLEANER - EAC is energized when there

is a blower speed call, except is NOT energized when blower

operates in the hard-wired continuous fan mode.

Furnace Control

The furnace control is preset at the factory with a fixed blower ON

delay of 30 seconds in the heating mode. The blower OFF timing is

preset at 140 seconds. If desired, the fan OFF delay can be reset to

obtain the longest delay times while still maintaining comfort lev-

els. See "Furnace Wiring Diagram".

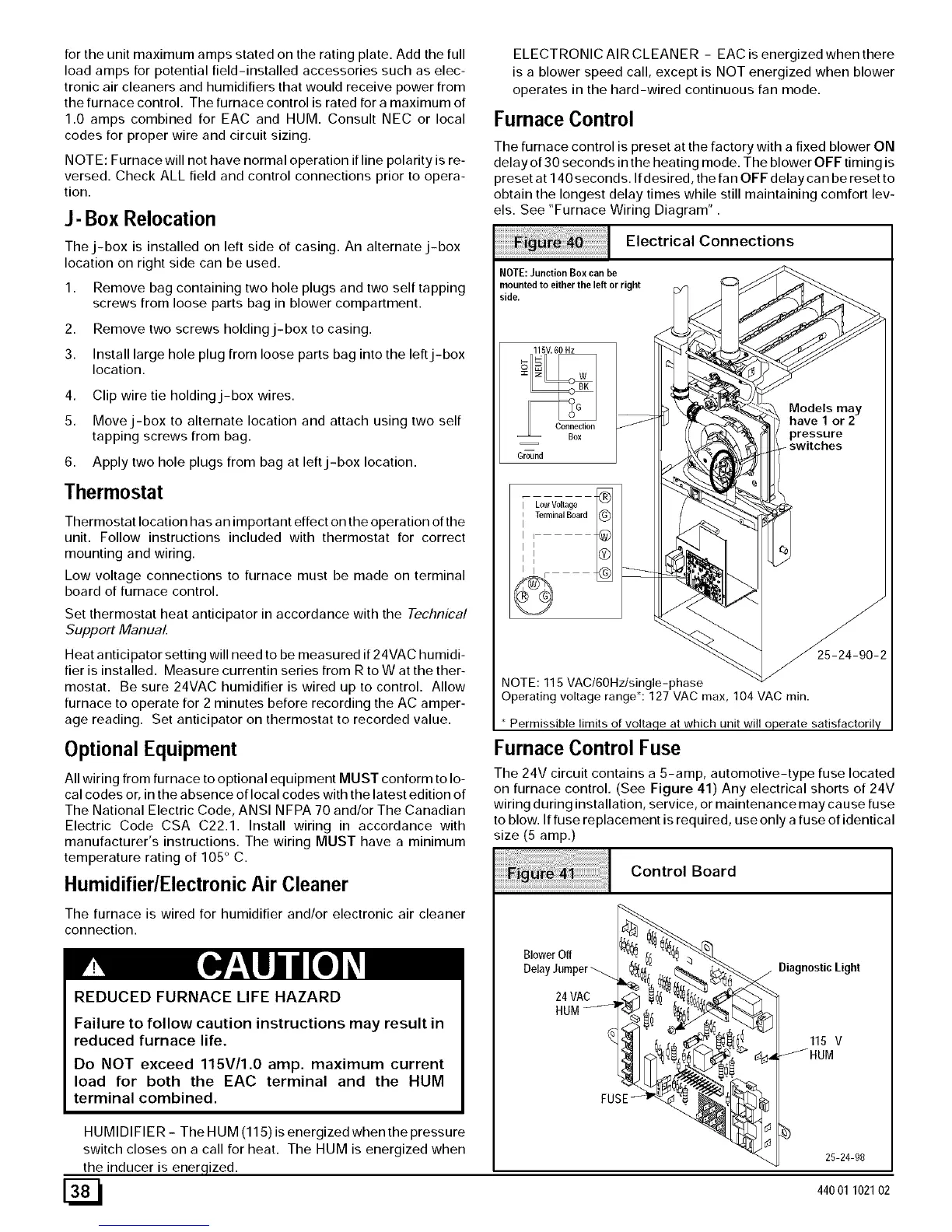

Electrical Connections

NOTE: Junction Box can be _//

mountedtoeithertheleftorright j

side.

:z z W

_:_, Models may

J have1or2

((_"%) ' pressure

\ _._________________d% _ switches

I TerminalBoard

NOTE: 115 VAC/BOHz/single-phase

Operating voltage range*: 127 VAC max, 104 VAC rain.

Permissible limits of voltaqe at which unit will operate satisfactorily

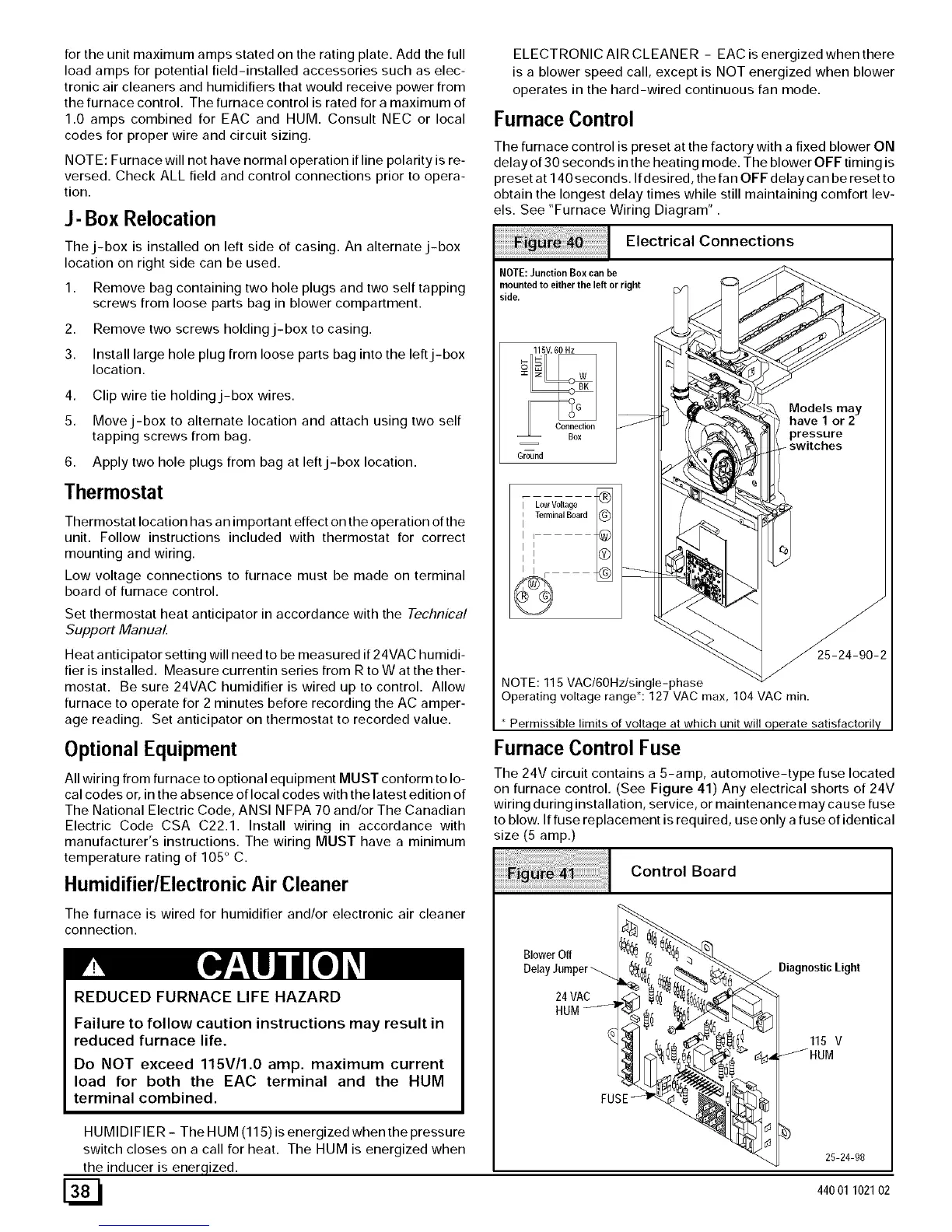

Furnace Control Fuse

The 24V circuit contains a 5-amp, automotive-type fuse located

on furnace control. (See Figure 41) Any electrical shorts of 24V

wiring during installation, service, or maintenance may cause fuse

to blow. If fuse replacement is required, use only a fuse of identical

size (5 amp.)

Control Board

BlowerOff

DelayJumper

24 VAC

HUM

DiagnosticLight

115 V

25-24-98

44001 102102

Loading...

Loading...