InCanada,provincialcodesmaygoverninstallationofswitch.

Checkwithgoverningauthorities.

Changing Orifices for High Altitude

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to properly install orifices could result in

death, personal injury and/or property damage.

Turn OFF electric power (at disconnect) and gas

supply (at manual valve in gas line) when installing

orifices. Installation of orifices requires a qualified

service technician.

2. Turn OFF gas supply to all appliances and start furnace.

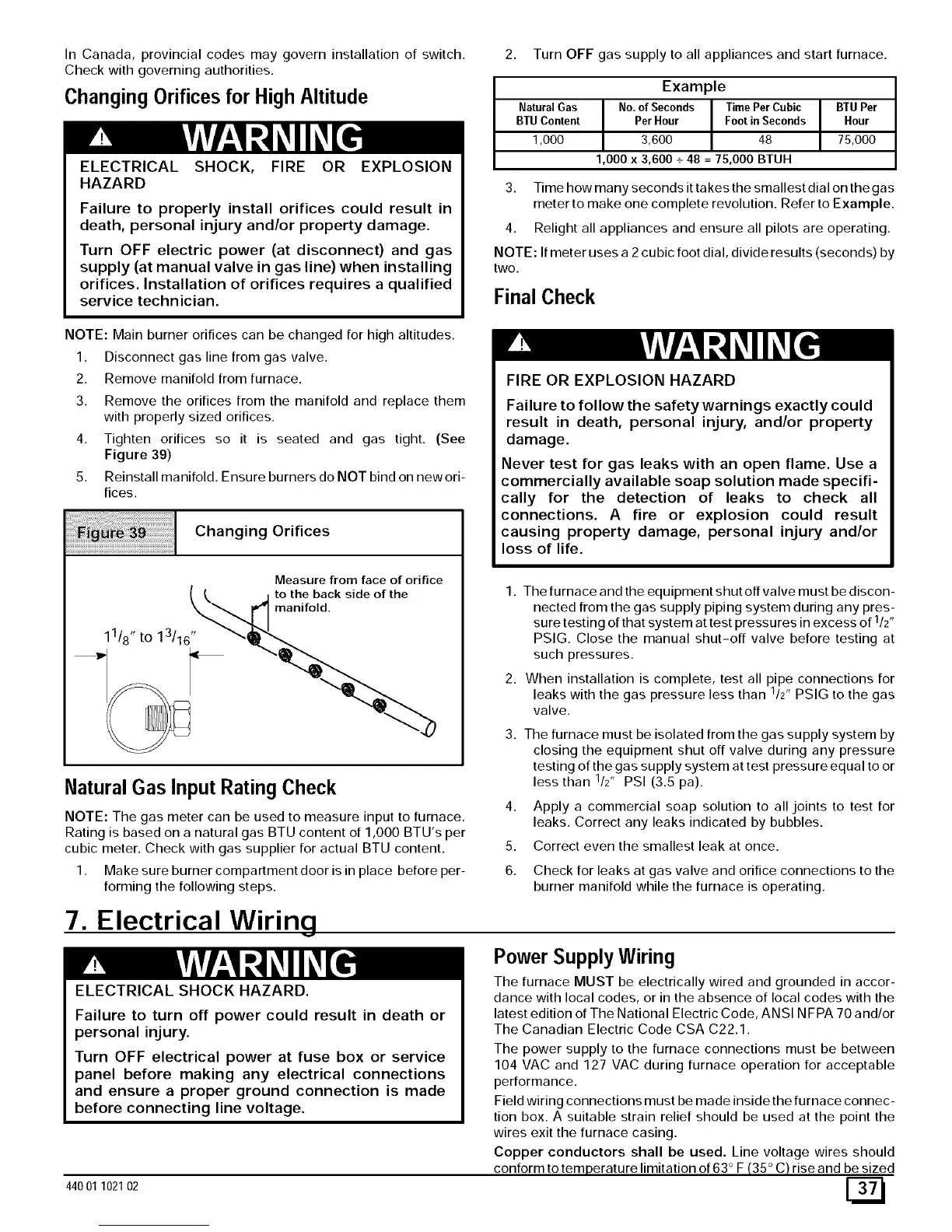

Example

.oturo,0ast .oo'Secondst 'imePerCubict "*°Per

BTU Content PerHour Footin Seconds Hour

1,000 3,600 48 75,000

1,O0O x 3,600 + 48 = 75,000 BTUH

3. Time how many seconds it takes the smallest dial on the gas

meter to make one complete revolution. Refer to Example.

4. Relight all appliances and ensure all pilots are operating.

NOTE: If meter uses a 2 cubic foot dial, divide results (seconds) by

two.

FinalCheck

NOTE: Main burner orifices can be changed for high altitudes.

1. Disconnect gas line from gas valve.

2. Remove manifold from furnace.

3. Remove the orifices from the manifold and replace them

with properly sized orifices.

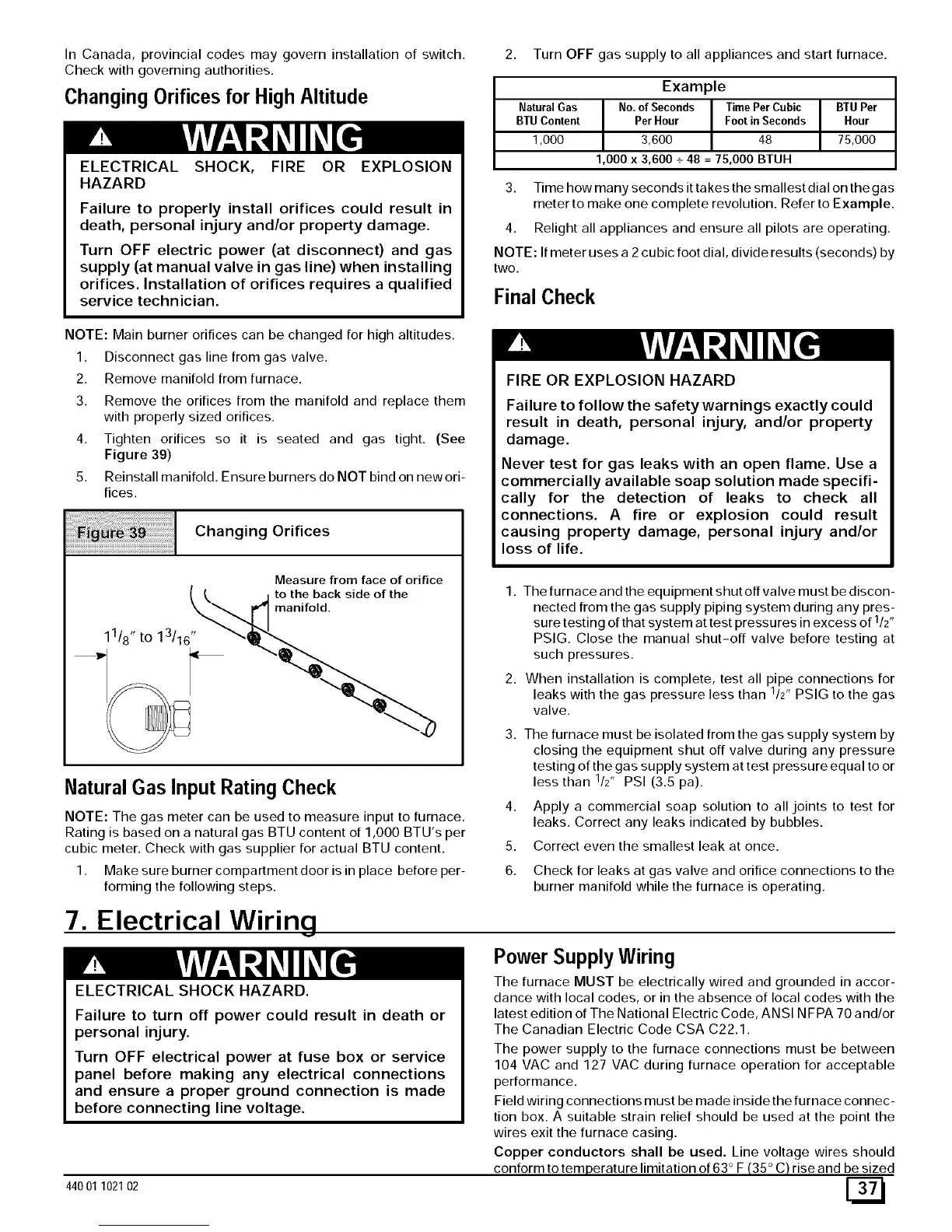

4. Tighten orifices so it is seated and gas tight. (See

Figure 39)

5. Reinstall manifold. Ensure burners do NOT bind on new ori-

fices.

11/8 " to 13/16"

Changing Orifices

Natural Gas Input Rating Check

Measure from face of orifice

to the back side of the

manifold.

2

NOTE: The gas meter can be used to measure input to furnace.

Rating is based on a natural gas BTU content of 1,000 BTU's per

cubic meter. Check with gas supplier for actual BTU content.

1. Make sure burner compartment door is in place before per-

forming the following steps.

7. Electrical Wiring

ELECTRICALSHOCK HAZARD.

Failure to turn off power could result in death or

personal injury.

Turn OFF electrical power at fuse box or service

panel before making any electrical connections

and ensure a proper ground connection is made

before connecting line voltage.

44001 102102

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in death, personal injury, and/or property

damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifi-

cally for the detection of leaks to check all

connections. A fire or explosion could result

causing property damage, personal injury and/or

loss of life.

1. The furnace and the equipment shut off valve must be discon-

nected from the gas supply piping system during any pres-

sure testing of that system at test pressures in excess of 1/2"

PSIG. Close the manual shut-off valve before testing at

such pressures.

2. When installation is complete, test all pipe connections for

1 ,

leaks with the gas pressure less than /2' PSIG to the gas

valve.

3. The furnace must be isolated from the gas supply system by

closing the equipment shut off valve during any pressure

testing of thegas supply system at test pressure equal to or

less than 1/2' PSI (3.5 pa).

4,

5.

Apply a commercial soap solution to all joints to test for

leaks. Correct any leaks indicated by bubbles.

Correct even the smallest leak at once.

6. Check for leaks at gas valve and orifice connections to the

burner manifold while the furnace is operating.

Power SupplyWiring

The furnace MUST be electrically wired and grounded in accor-

dance with local codes, or in the absence of local codes with the

latest edition of The National Electric Code, ANSI N FPA 70 and/or

The Canadian Electric Code CSA C22.1.

The power supply to the furnace connections must be between

104 VAC and 127 VAC during furnace operation for acceptable

performance.

Field wiring connections must be made inside the furnace connec-

tion box. A suitable strain relief should be used at the point the

wires exit the furnace casing.

Copper conductors shall be used. Line voltage wires should

conform to temperature limitation of 63 ° F (35 ° C) rise and be sized

Loading...

Loading...