GENERAL GUIDANCE ON APPLICATIONS

Frame 10 is intended to provide basic information only on the

application of the Ideal Concord Super boiler. British Gas

approval has not been sought in the matter.

It is impossible to cover all applications and installers are

recommended to contact Ideal Boilers if advice on a specic

application is required.

It is essential that the water ow rates given in Table 1 &

2 be maintained within the limits stated - therefore any

compensating devices must not be connected to Ideal

Concord Super boilers directly but may be used in

conjunction with a mixing header. The mixing header must

be sized at least one pipe size larger than the boiler ow and

return manifold size. This will avoid hydraulic interference

between the boiler primary pump and system zone pumps.

The use of a mixing header means that compensating

controls can be used to operate mixing valves on a variable

temperature circuit, without affecting the water ow rate

through the boiler.

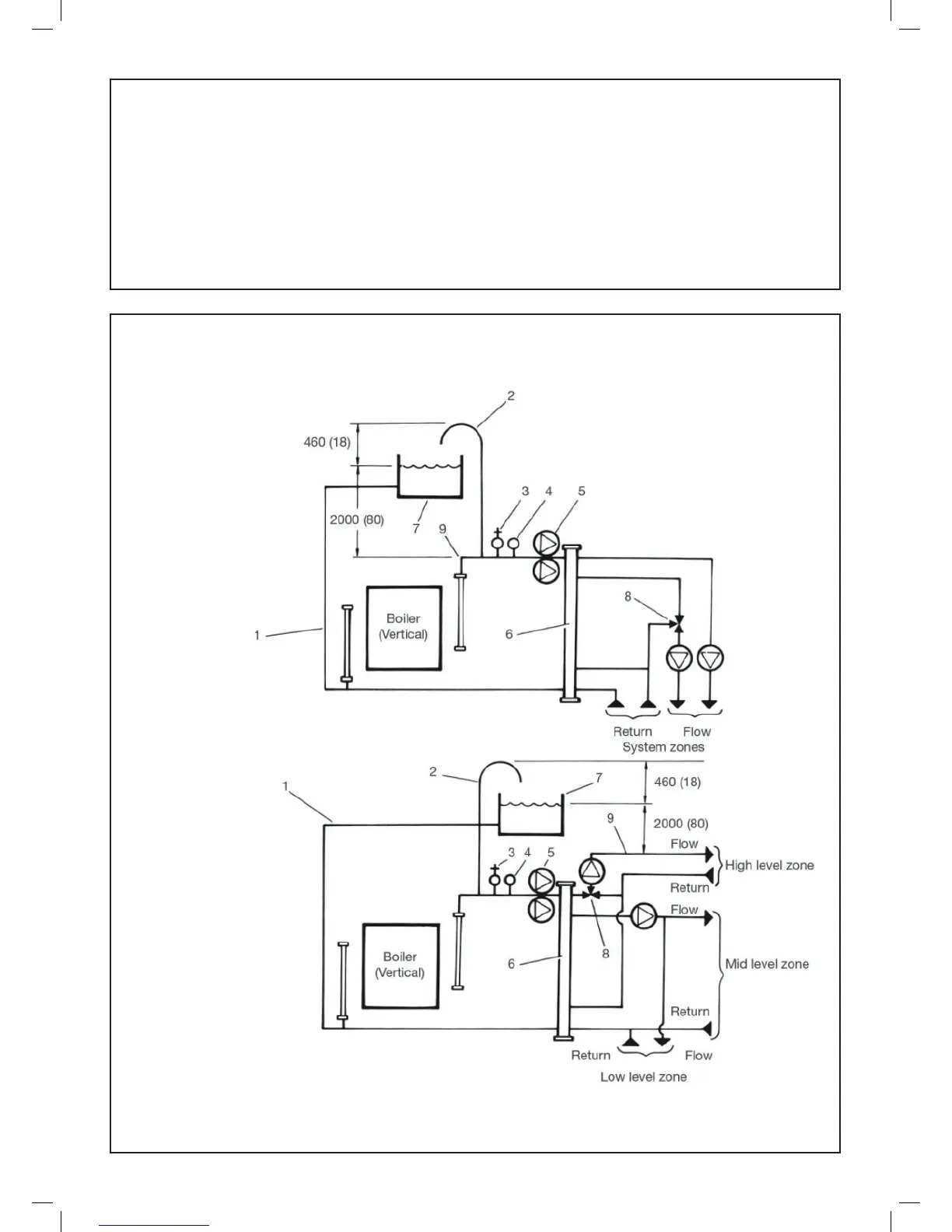

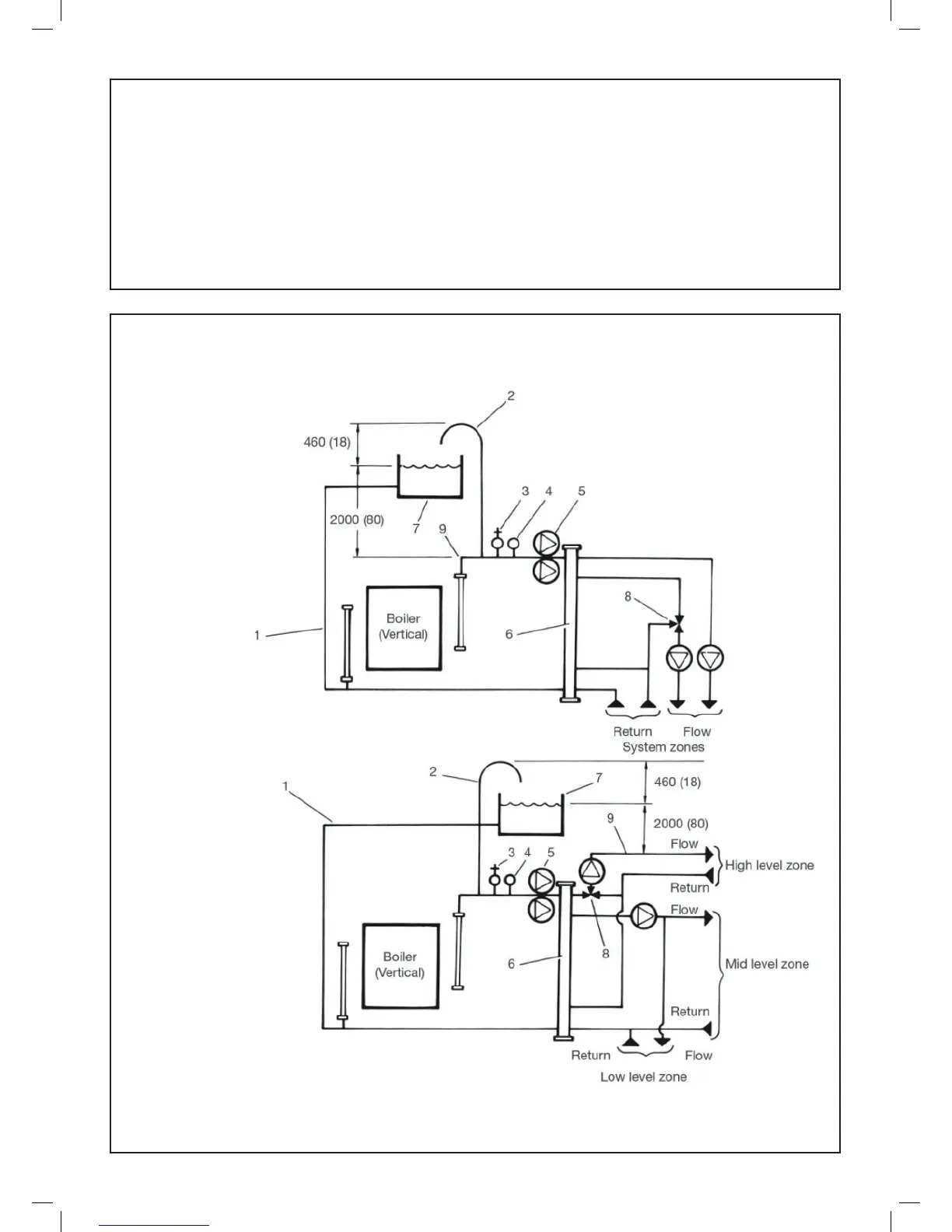

10 GUIDE TO MINIMUM REQUIREMENTS FOR OPEN VENT - Feed / Expansion Tank

Height and Boiler Primary Circuit

1. Roof top or single storey applications.

2. Ground oor or basement applications.

1. Cold Feed

(sizes MUST comply

with BS. 6644).

2. Open vent.

(sizes MUST comply

with BS. 6644).

3. Safety valve.

4. Water ow switch.

5. Dual primary pumps.

6. Mixing header

- see note above.

7. Feed and expansion tank.

8. Mixing valve.

9. Highest point in the system.

All dimensions in millimetres (inches)

LEGEND

GENERAL

Loading...

Loading...