SERVICING INSTRUCTIONS

IMPORTANT

In order to ensure safe and reliable operation of Ideal

Concord Super boilers it is essential that regular

maintenance be carried out by competent staff who have

received instruction in maintenance, fault nding and

commissioning procedures for this boiler series.

ANNUAL servicing is recommended.

BEFORE CARRYING OUT ANY SERVICING PROCEDURE:

1. Isolate the boiler electrical supply.

2. Turn off the gas service tap on the module being

serviced.

3. Be aware that the 4 mm pipes connecting the gas valve

to the gas/air control unit are factory sealed and MUST

NOT be disturbed.

The following procedure should be carried out annually.

Preparation for servicing.

Possible spares required:

Fan motor impellor housing gasket.

Round cork burner gasket.

Round foil-faced glass-bre gasket complete with ‘U’ shaped

extension.

Square cork fan outlet gaskets (2).

Ignition electrode with lead.

Flame sensing probe with lead.

1. Unscrew the two retaining screws from the front of the

orange cover and remove the cover.

2. Withdraw the multi-pin plug from the left-hand side of the

module and switch off the module on/off switch.

3. Unscrew the M5 screw at the right-hand side of the rear

control panel (see Frame 19) & swing the panel to the

left.

4. Disconnect the lead to the ignition electrode from Board

No. 29 control box and withdraw it through the cable tie

wrapped round the return elbow behind the gas valve.

5. Release the fan motor lead and mains harness lead from

the clip at the left-hand side underside of the fan plate.

6. Unfasten the plug and socket connection to the fan

motor.

7. Unfasten the plug and socket connection to the ame

sensor.

8. Undo the 6 mm suction sensing line union connections

at the ‘square to round’ casting and at the gas/air control

unit and remove the sensing line.

9. Undo the 6 mm pressure sensing line union connections

at the fan housing base and at the gas/air control unit and

remove the sensing line.

10. Undo the 3 elongated M8 nuts with slotted heads,

securing the fan assembly.

11. Remove the fan assembly, taking care not to damage the

fan impellor.

12. Disconnect the burner earth lead from the earthing post

at the left-hand rear side of the chassis.

13. Remove burner completed with its integral ignition

electrode.

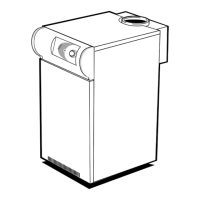

Servicing the ignition electrode and burner

1. Brush the inside and outside of the burner, making sure

to clear any blockages in the burner.

2. If the burner shows any sign of deterioration it should be

replaced.

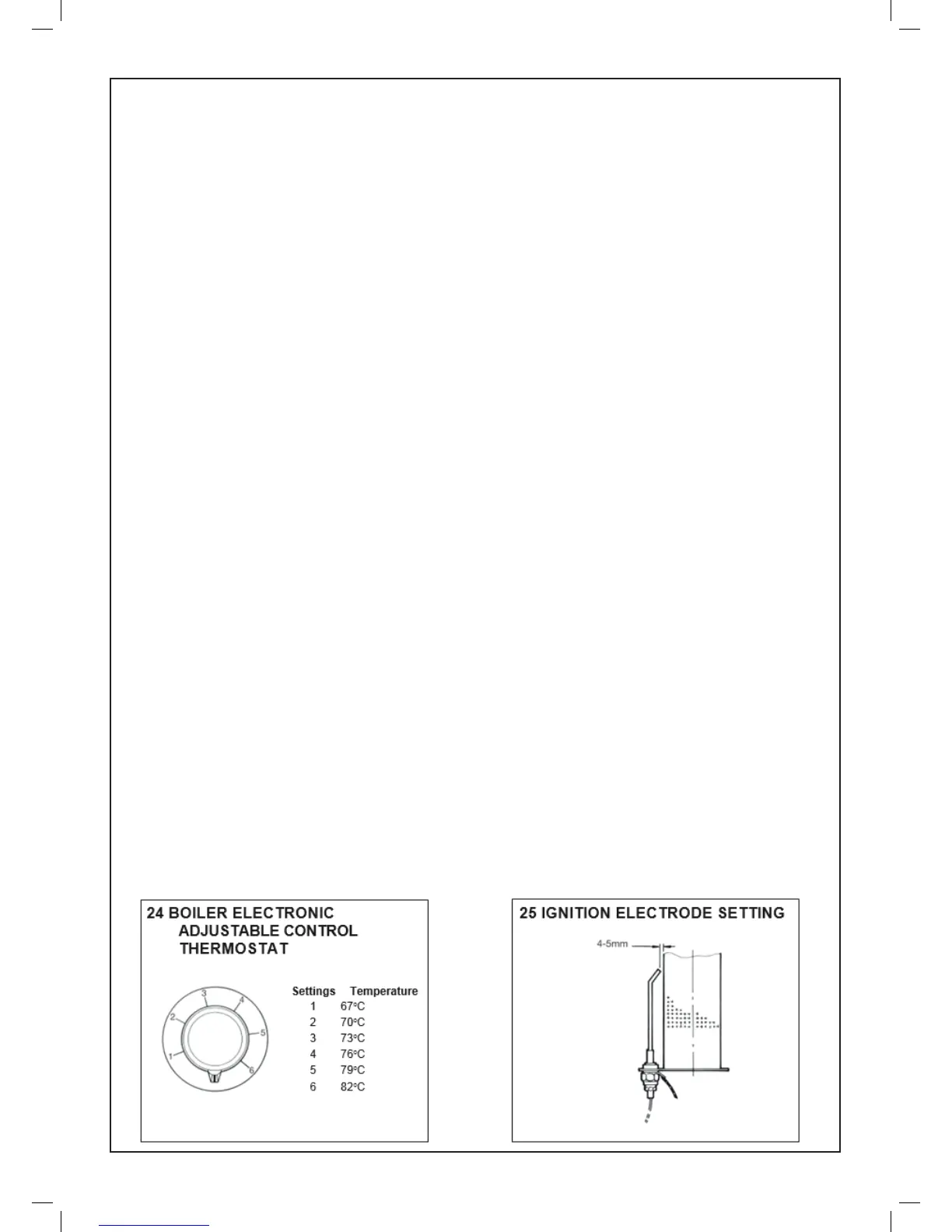

3. Inspect the ignition electrode. If it shows any sign of

erosion or if there is damage to the insulation or integral

lead, it should be replaced.

Undo the retaining nut and withdraw the electrode from

its housing. Fit new electrode.

4. Check the spark gap and adjust, if necessary. It should

be 4-5 mm - see Frame 25.

Servicing the ame sensing probe

Undo the retaining nut and withdraw the probe. If it shows any

signs of erosion, damage to insulation or to the integral lead

IT MUST BE REPLACED.

Inspecting the nned tubes of the heat exchanger(s)

Inspect the DRY side of the heat exchanger nned tubes by

viewing through the burner opening, using an electric torch

and mirror.

In general, on intermittently operated systems, it will not be

necessary to undertake chemical cleaning more than once

every two years although, as mentioned above, the DRY side

should be examined at least once a year to assess the rate of

build up of debris.

When systems are operated virtually continuously, heat

exchangers should not exceed 3,000 hours ring time

between chemical cleaning. For instructions on chemical

cleaning, see relevant section.

SERVICING AND FAULT FINDING

Loading...

Loading...