11

SYSTEM TEMPERATURE

CONTROL KITS

FLUE SYSTEMS

DIFFERENTIALS

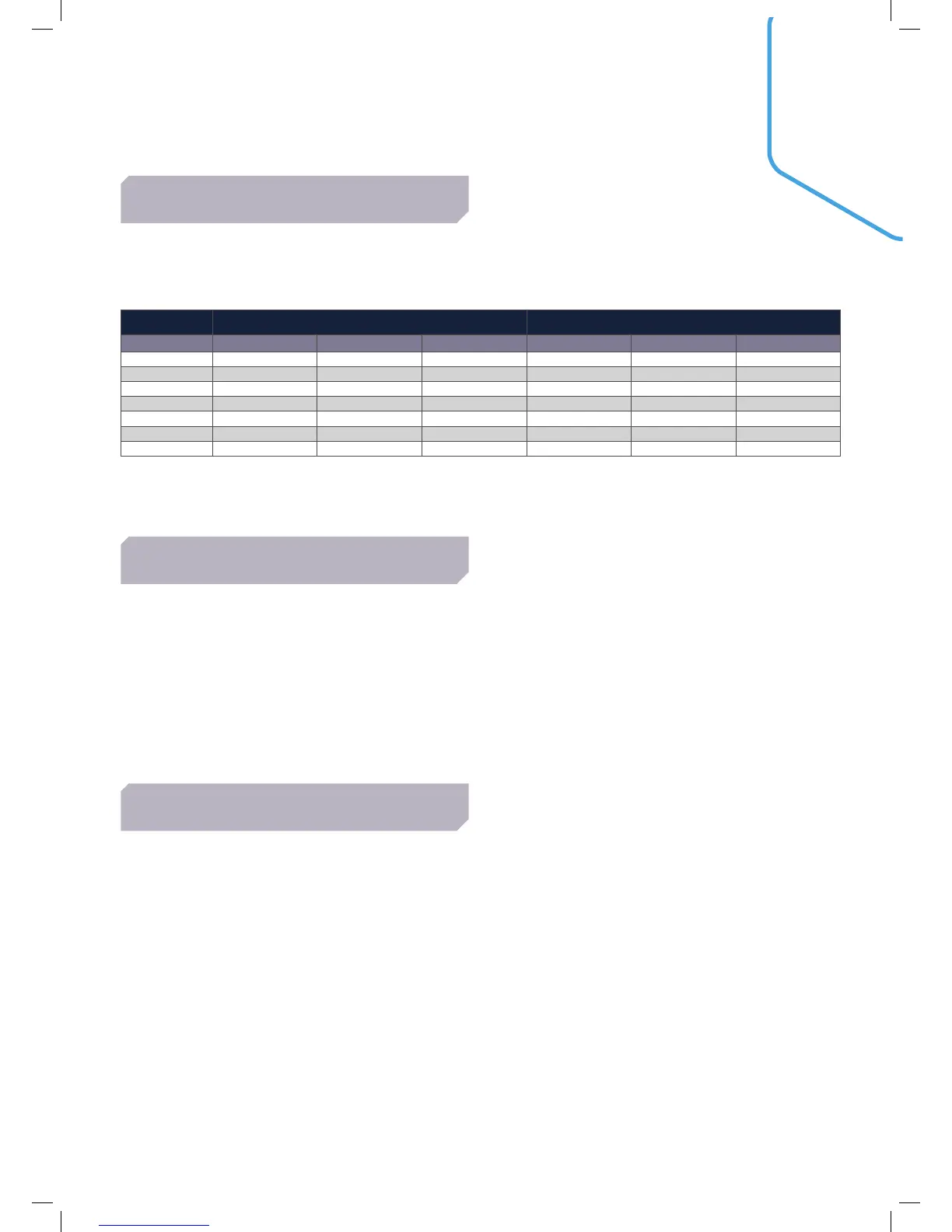

Flow rates for common systems using either 11°C, 15°C or 20°C temperature differentials

are given in the table below.

FLOW RATE (L/MIN) HYDRAULIC RESISTANCE (MBAR)

BOILER 11°C 15°C 20°C 11°C 15°C 20°C

Evomax 30 / 30P 39.1 28.7 21.5 425 225 127

Evomax 40 / 40P 52.1 38.2 28.7 875 405 225

Evomax 60 / 60P 78.2 57. 3 43.0 435 180 83

Evomax 80 / 80P 104.2 76.4 57.3 750 420 180

Evomax 100 N/A 95.6 71.7 N/A 315 134

Evomax 120 N/A N/A 86.0 N/A N /A 218

Evomax 150 N/A N/A 107.5 N/A N /A 230

• 30-80 kW boilers must operate with temperature differentials from 11 to 20°C.

• 100 kW boilers must operate with temperature differentials not less than 15 to 20°C.

• 120-150 kW boilers must operate with temperature differentials not less than 20°C.

See pages 74-77 for further system requirements

A comprehensive range of flue kits are available from

Ideal Commercial Boilers including horizontal and vertical

concentric and open flue options.

For horizontal flues: this is the distance from the flue outlet

centre line on the boiler to the outside wall. Horizontal flue

termination is not available for Evomax 150.

For vertical flue: this is the distance from the top of the

boiler case to the aperture in the weather collar. If elbows

are to be used, then the equivalent length of that fitting

must be subtracted from the maximum flue extensions

allowed for that flue option.

Note: Horizontal terminal resistance includes 1 x 90° elbow.

When installing Evomax boilers with concentric flue

(horizontally or vertically) the Ideal Commercial flue

system must be used.

The resistance of flue components, together with the

maximum flue resistance each boiler can work against, may

be used to calculate the total flue resistance of the system,

and to determine if they are acceptable to run on the boiler.

Multiple boilers may be installed with a common

flue header.

The flue system should be designed and supplied by a

specialist flue company. BS 6644 and IGEM UP/10 provide

guidance on design and the drainage of condensate from

flue stack and headers. Condensate from a flue stack and

header must be collected and drained before entering

the boiler.

For Ventilation requirements please refer to the

installation manual..

PROGRAMMABLE ROOM THERMOSTAT KIT.

Timed control of central heating. Includes a built in

electronic room sensor, optimised start and on/off

controlled DHW.

MODULATING SEQUENCER KIT.

Controls up to 5 boilers for cascade operation.

Air and Flow Header sensors are included.

OUTSIDE SENSOR KIT.

Provides weather compensation directly or with

Programmable Room Thermostat kit.

TANK SENSOR KIT.

Provides DHW temperature control. Also for use with

Sequencer kit.

ROOM SENSOR KIT.

Used with Modulating Sequencer kit for CH control.

SAFETY INTERLOCK KIT.

Provides boiler shut down via an external signal.

Loading...

Loading...