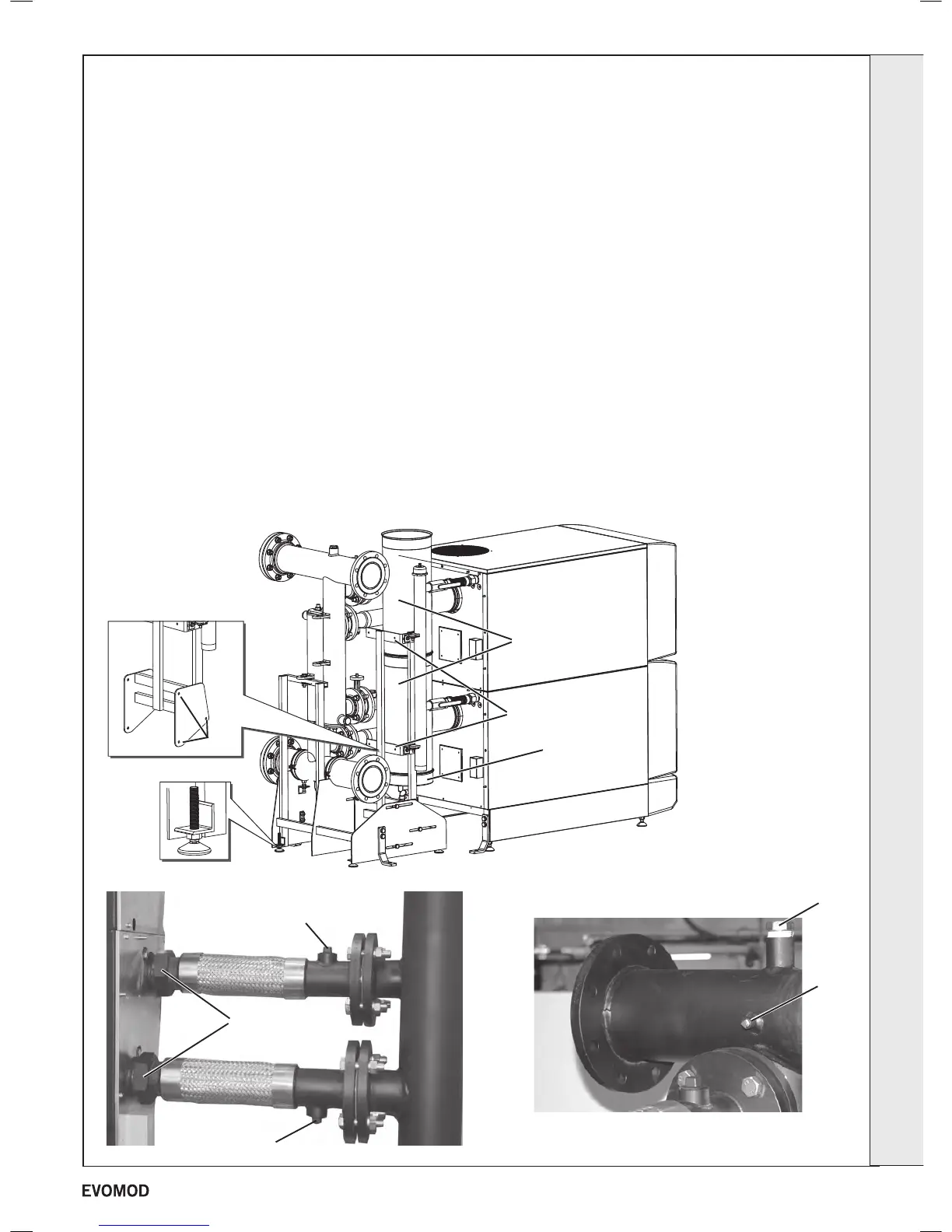

Flue header support frame

screws

Bottom

cap

T Pieces

Flue Support Brackets

Adjustable

feet

The ue header is supplied as standard with the boiler (not

250 model).

See table on page 5 for guidance on maximum permissible

ue duct system design

The water and gas header system is supplied as a fully

assembled self supporting unit capable of connecting the

water and gas services direct to the rear of the module/s.

500kW & 750kW (see Frame 17 for 1000kW)

1. Assemble the ue manifold T pieces (long legs point upwards),

ensuring the seals are tted and lubricated using the seal

lubricant provided.

2. Push the assembled T pieces into the boiler connections

ensuring the seals are tted and lubricated using the seal

lubricant provided.

3. Unpack and position the header assembly at the rear of the

boiler.

4. Use the adjustable feet to both level the unit and position the

unions adjacent to their respective module connections.

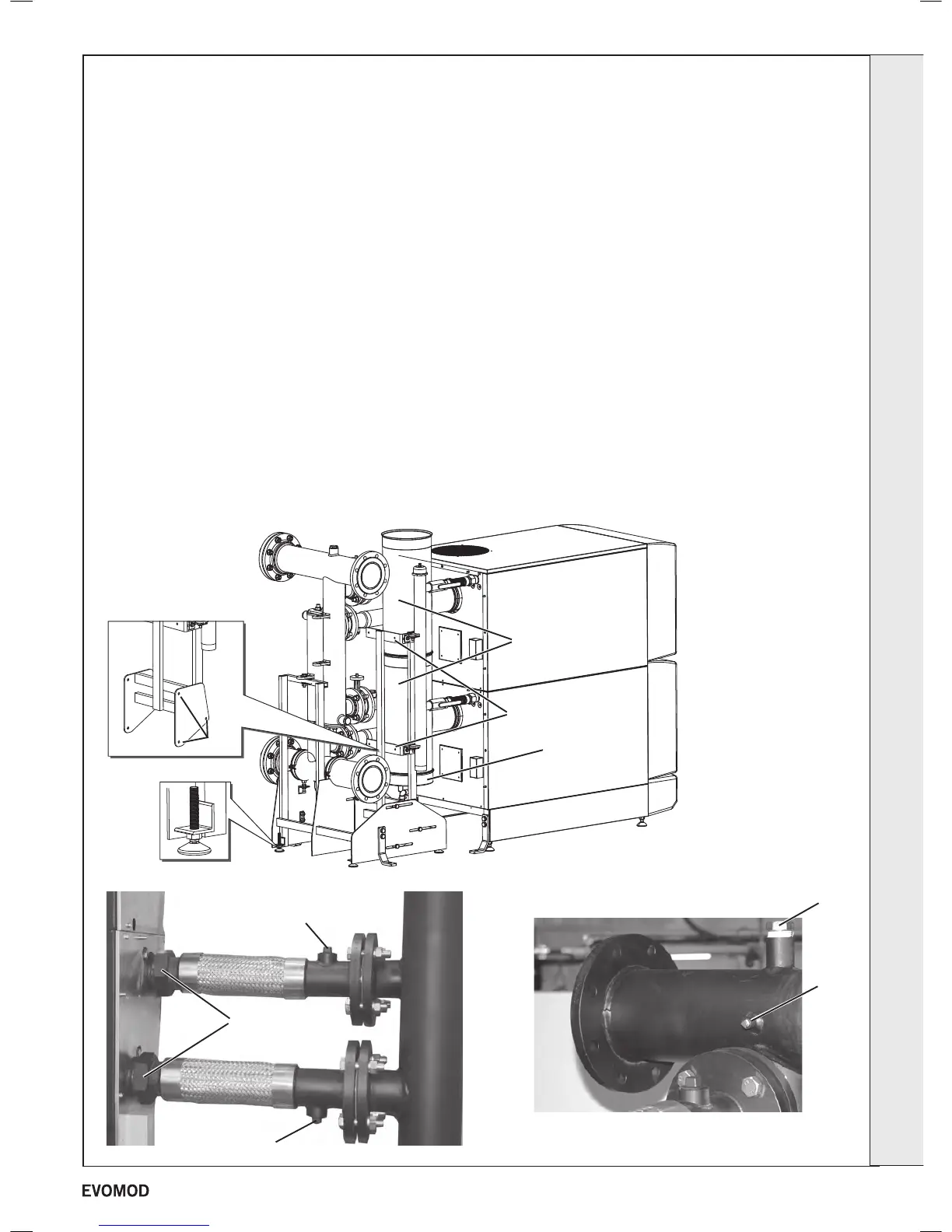

5. Connect each header ow & return exible hose connection

to the appropriate module male thread using the bre washer

provided. Note: A number of adjustments are available within

the header assembly to help align connections. These must be

secured after any adjustments.

6. An air vent point is provided in the top of the ow header and an

automatic air vent MUST be tted.

7. If the header kit used includes isolation valves, a pressure relief

valve MUST be tted to the 1” boss provided on the exible ow

pipe of each module.

8. A 1” boss is provided on the underside of the exible return pipe

to enable a drain valve to be tted.

9. The header thermistor MUST be tted to the boss provided on

the header ow pipe.

10. Connect each exible gas header pipe to the appropriate

module male thread. Note: A number of adjustments are

available within the header assembly to help align connections.

These must be secured after any adjustments.

11. Secure the ue manifold to the header frame with the 2 support

brackets provided. Note: The frame that supports the ue

manifold & gas header can move forwards or backwards for

adjustment.

12. Fit the bottom cap to the ue manifold & secure with one of the

locking bands provided. Use the remaining locking bands to

secure the ue manifold T pieces together. Note: This bottom

cap must be connected to a drain via a water trap using plastic

components only.

Refer to frames 1-4 for

dimensions.

The header ow and return

pipes are terminated with two

2

1

/2" PN16 anges (250 model)

and 5" PN16 anges (500, 750

and 1000 models). For 1000

models, the headers are bolted

together at the anges.

Flushing

If installing onto a new or

existing system it is strongly

recommended that the

system be thoroughly ushed

in accordance with the

requirements of BS:7593 before

connecting the boiler.

PRV 1" Boss

Header ow &

return connections

Auto air vent boss

Header

thermistor

boss

Drain valve boss

16

WATER AND GAS HEADER INSTALLATION

INSTALLATION

continued . . . . . .

19

- Installation & Servicing

Loading...

Loading...