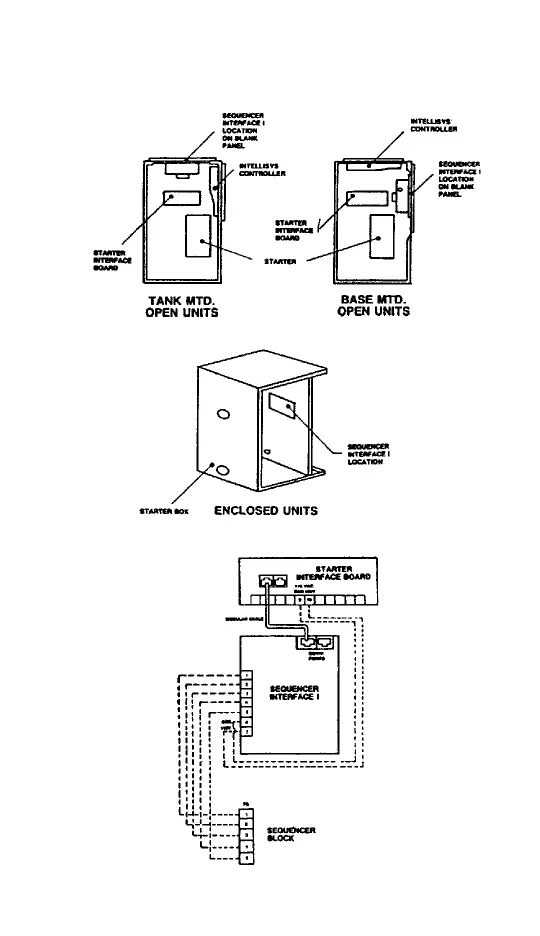

FIGURE 1

INTERFACE MOUNTING LOCATION

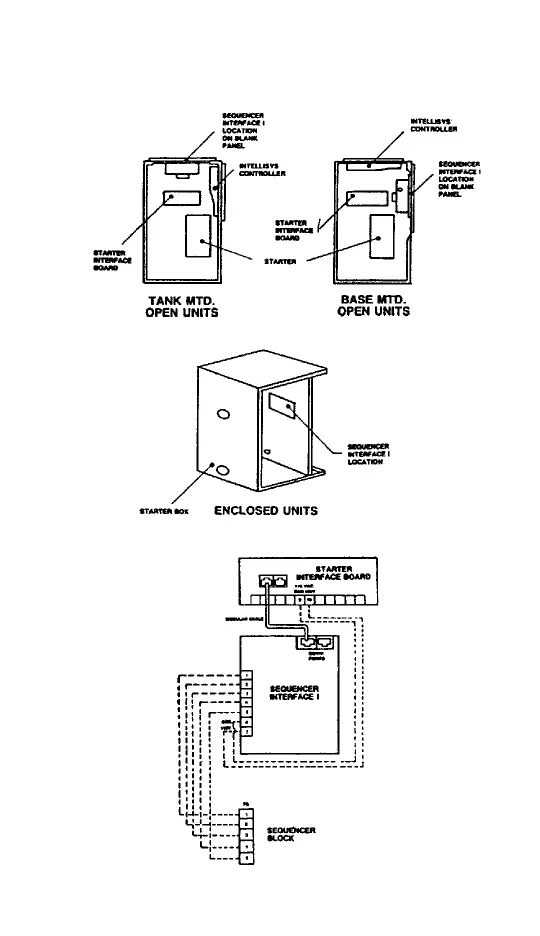

FIGURE 2 - WIRING DIAGRAM

SEQUENCE CONTROLLER INSTRUCTIONS

FOR MODELS:

SSR 10-450 HORSEPOWER

TWO, THREE, FOUR OR FIVE UNIT COMPRESSOR INSTALLATIONS

When two or more compressors, each designed for automatic start-up control,

operate together one should always be the “lead” unit. If this “lead” compressor

can maintain the required plant air pressure, all other compressors should be set

to shut down. This can be done by setting all compressor off line values at

different settings. The obvious result of doing this is that the compressors do not

log equal operating hours-the compressor with the pressure switch set at the

highest pressure level will log far more hours than the other compressors.

To make any compressor a lead machine and, on a rotative basis, equalize the

operating hours for each of the compressors, a sequence controller is used. By

interconnecting a rotary drum switch and a group of auxiliary pressure

switches(one for each compressor), it is possible to revise the order of automatic

operation of the compressors without making individual adjustments to the

compressors. Each pressure switch in the sequence controller senses line

pressure, (introduced via a manifolded tubing assembly), and controls the

compressor to which it has been connected electrically.

A three compressor installation in a plant which has a minimum pressure

requirement of 90 psig could have its sequence controller pressure switches set

as follows-using varying pressure differential settings.

After time delay, each compressor will shut down at or above its “switch opening

pressure” and will automatically re-start at the “reset pressure”. From the setting

shown, step rotation of the sequence selector switch connects the pressure

switch 1 to the control leads of compressor No. 2, making it the lead machine-

and pressure switch II to compressor No. 3 making it the No. 1 lag compressor.

Compressor No. 1 which was the lead machine would become the No. 2 lag unit.

One more step of switch rotation continues the progression, so that each

compressor, in turn, becomes the lead unit.

A pointer, on the sequence panel face, indicates which unit is in the lead position.

Local-sequence selector switches, one for each compressor are mounted on

the sequence controller. These switches enable an operator to put any

compressor in sequence control or local control.

An indicating light, mounted above each selector switch, is lit when its corre-

sponding compressor is placed in sequence control.

When a compressor is in local control, it will operate in the automatic start-stop

mode but under the control of its own pressure switch (1PS).

SWITCH OPENING RESET

COMPRESSOR PRESSURE POSITION PRESSURE (PSIG) PRESSURE (PSIG)

1 I LEAD 100 94

2 II 1 LAG 98 92

3 III 2 LAG 95 90

-33-

-34-

Loading...

Loading...