Appendix II 48

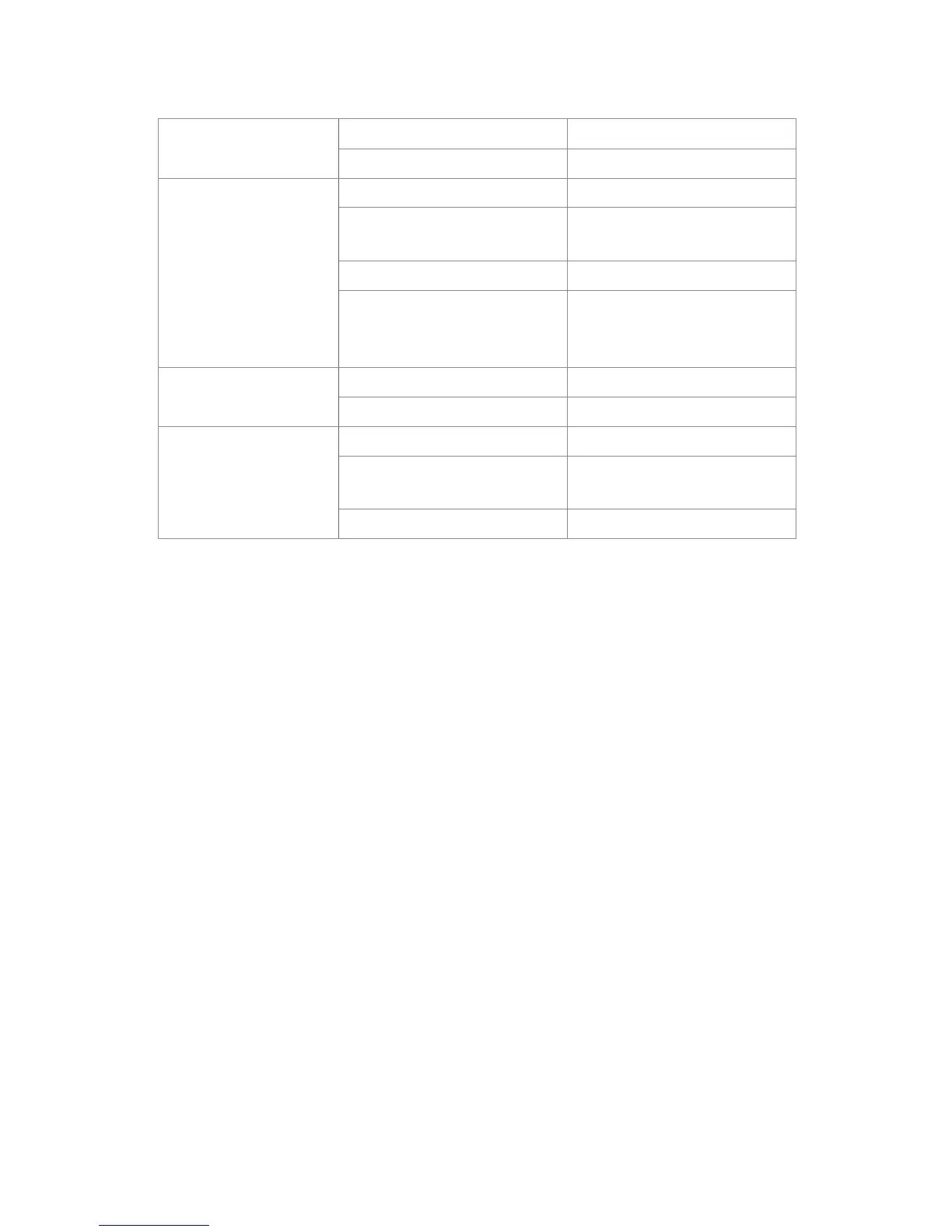

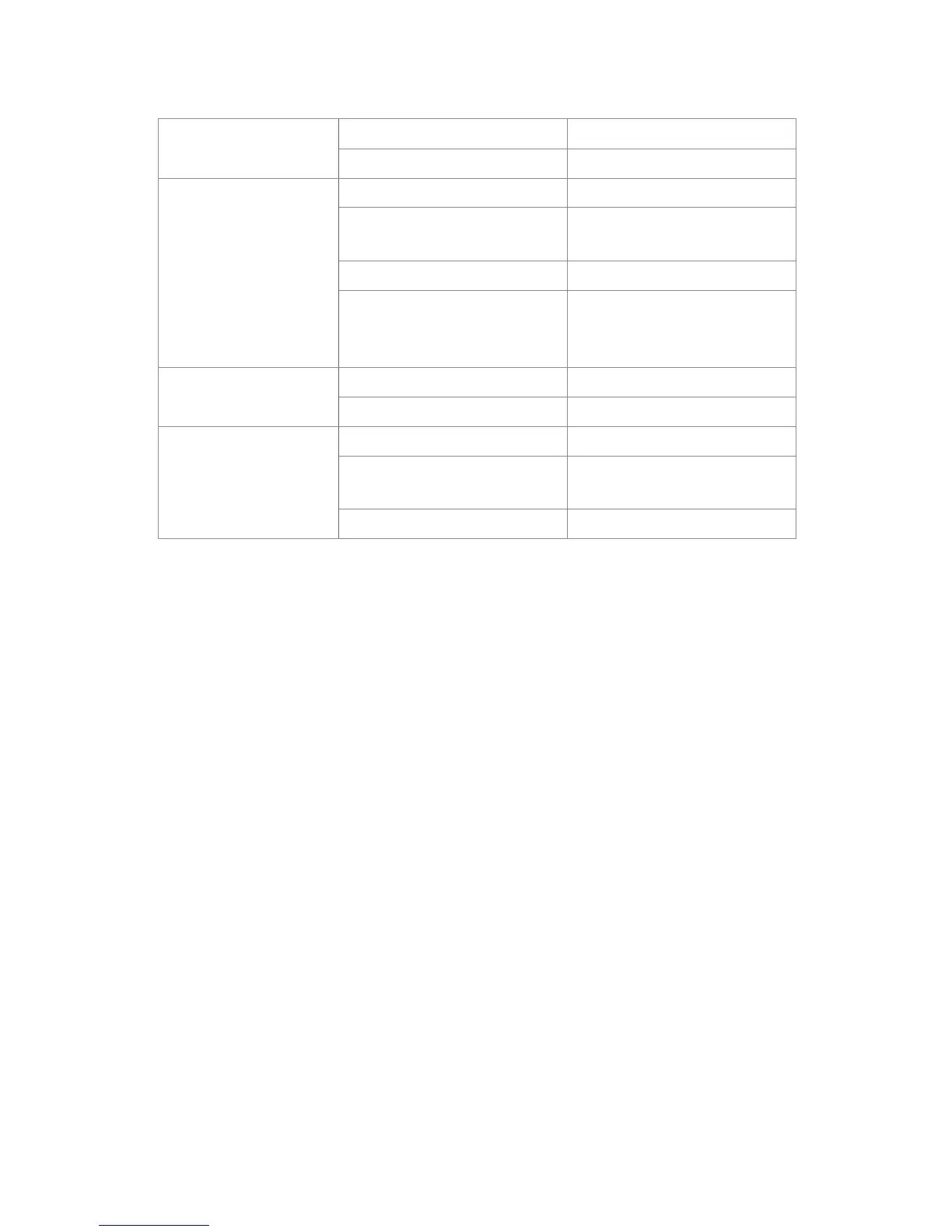

Fiber Axis Align Failed

Too large axial offset (>4.0㎛).

Re-prepare the bers.

The motor is not calibrated. Perform [Motor calibration].

Fiber is Dirty

Dust or dirt on the ber surface. Prepare the ber again.

The lenses are covered with dust.

Perform [Dust check] after

cleaning the lenses.

[Clean Arc Time] is too short. Set [Clean Arc Time] to 180ms.

It is difcult to identify the ber

core by using the method of core

alignment to splice.

Use MM splice mode (clad align-

ment) to splice the unidentied

ber core.

Fat Splicing Point

[Overlap] is too much. Adjust [Overlap] parameter.

The motor is not calibrated. Perform [Motor Calibration].

Thin Splicing Point

Arc power is too low. Perform [Arc Calibration].

The level of pre-discharge is

too high.

Decrease pre-discharge or pre-

discharge time.

Insufcient [Overlap]. Adjust [Overlap] parameter.

Loading...

Loading...