79

Hydraulic power supply (HPS)

Product Support: www.instron.com

Hydraulic power supply (HPS)

The HPS should be maintained according to the “Preventative maintenance schedule” on page 61.

Check the oil cleanliness

The cleanliness of the oil in the reservoir should be checked at the frequency stated in the “Preventative

maintenance schedule” on page 61. Check the appearance of the oil through the sight gauge; it

should be a clear amber color. If the oil appears dirty, it should be changed (see “Change the oil” on

page 83).

Add oil to reservoir

It should only be necessary to add oil to the reservoir if an oil leak is evident. However, the oil level

should be checked at the frequency stated in the “Preventative maintenance schedule” on page 61.

Check the oil level through the sight gauge on the HPS. The oil should be to the top of the sight gauge

when the frame’s hydraulic cylinder is fully retracted. When it is necessary to add oil, perform the

following procedure.

Equipment and supplies required

• A 4 mm hex key (supplied)

• A clean funnel with a mesh filter

• Clean towels, rags, or similar

• Hydraulic fluid (amount required depends on how much is needed to sufficiently fill reservoir), for

fluid specifications see “Oil type and quantity” on page 86

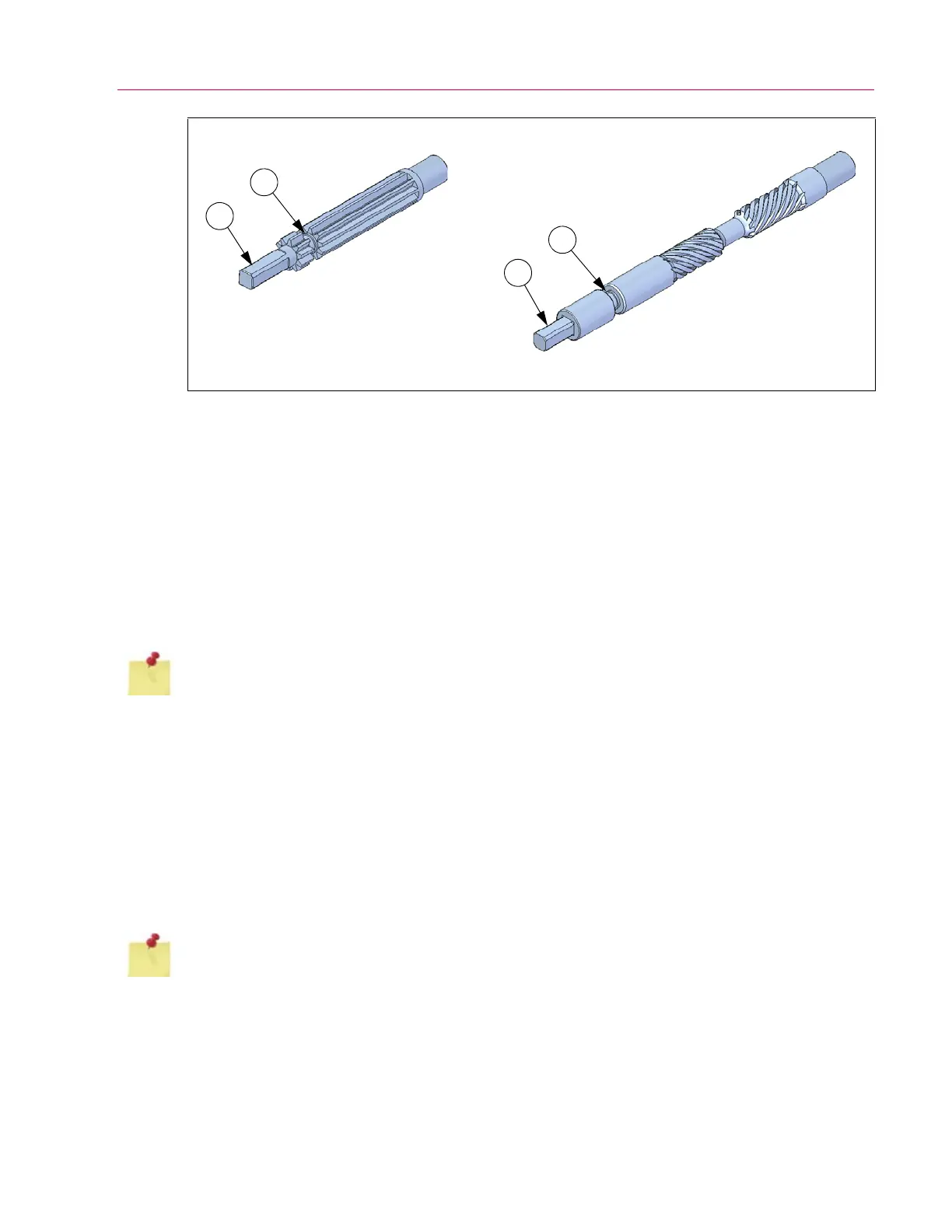

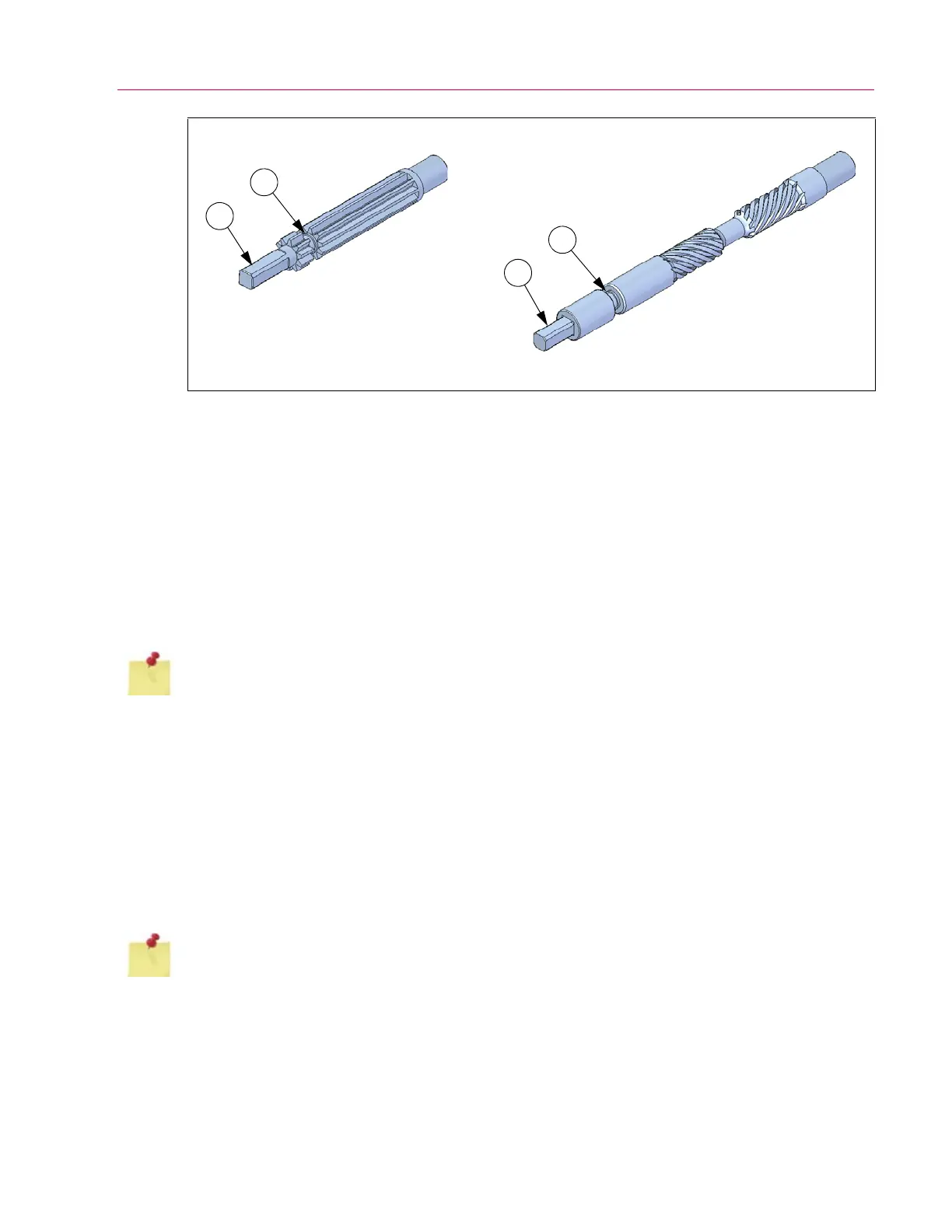

Figure 19. Pinion.

Pinion for 300DX

Pinion for 600DX

1. Groove for setscrew

2. Square end for crank handle

1

2

1

2

In the United States and Canada, an oil sample test kit is available for purchase from Instron Services;

contact your local Instron Services department as directed on page 20 for more information about the

test kit.

All equipment and supplies must be supplied by the customer unless noted as “supplied”. For a list of

equipment that was supplied with the system, refer to “Ancillary parts” on page 87.

Loading...

Loading...