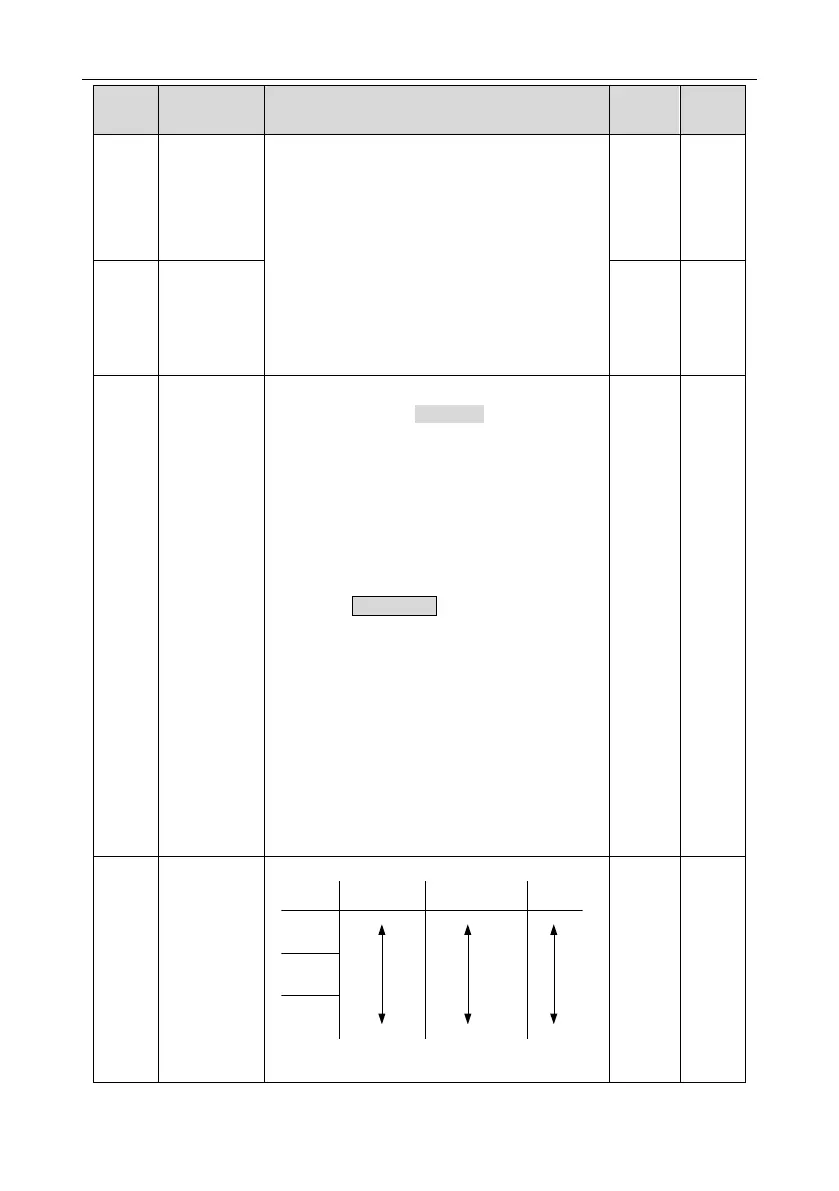

ACC time means the time needed if the VFD

speeds up from 0Hz to the max. one (P00.03).

DEC time means the time needed if the VFD

speeds down from the max. output frequency to

0Hz (P00.03).

Goodrive200A series VFDs define four groups of

ACC/DEC time which can be selected by P05.

The factory default ACC/DEC time of the VFD is

the first group.

Setting range of P00.11 and P00.12: 0.0–3600.0s

0: Runs at the default direction, the VFD runs in

the forward direction. FWD/REV indicator is off.

1: Runs at the opposite direction, the VFD runs in

the reverse direction. FWD/REV indicator is on.

Modify the function code to shift the rotation

direction of the motor. This effect equals to the

shifting the rotation direction by adjusting either

two of the motor lines (U, V and W). In keypad

control, the motor rotation direction can be

changed by QUICK/JOG on the keypad. Refer to

parameter P07.02.

Note: When the function parameter comes back

to the default value, the motor’s running direction

will come back to the factory default state, too. In

some cases it should be used with caution after

commissioning if the change of rotation direction is

disabled.

2: Forbid to run in reverse direction: It can be used

in some special cases if the reverse running is

disabled.

Loading...

Loading...