Goodrive350 series high-performance multi-function inverter Chapter 5

-57-

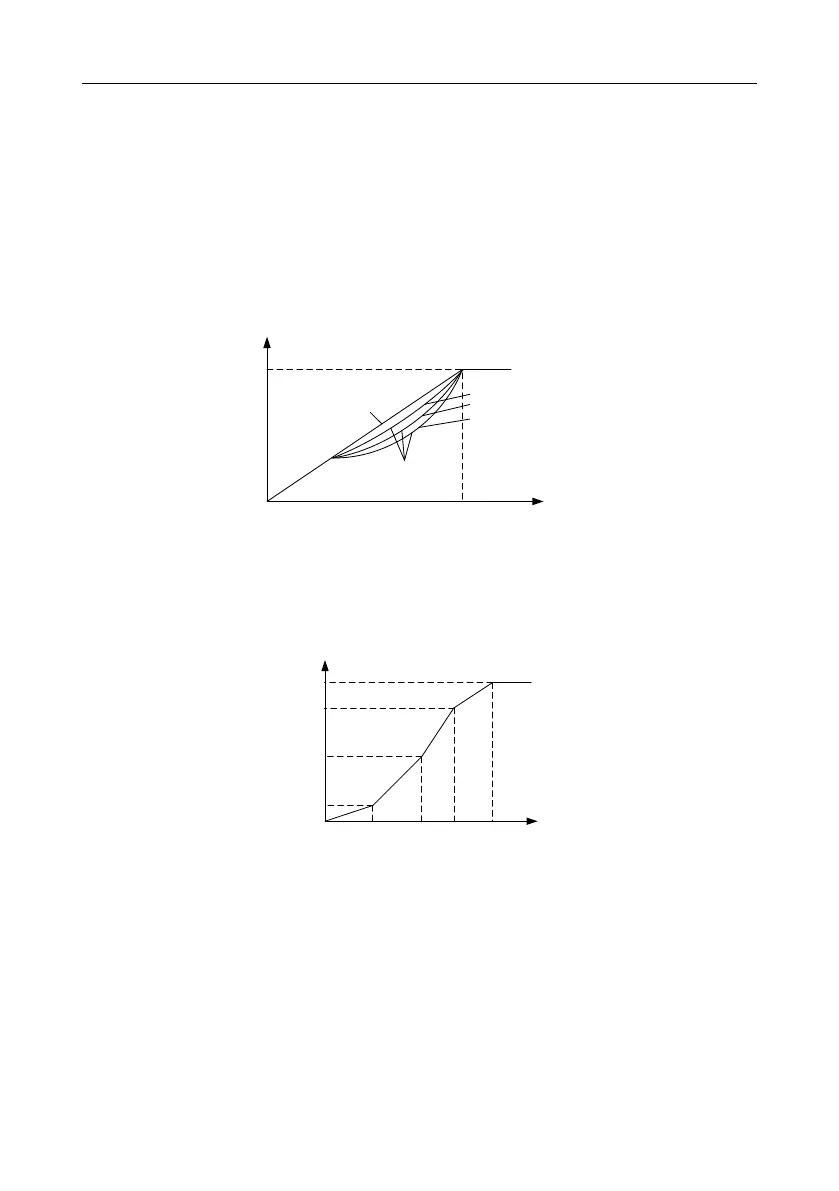

GD350 inverter provides multiple kinds of V/F curve modes to meet different field needs. Users can

select corresponding V/F curve or set the V/F curve as needed.

Suggestions:

1. For the load featuring constant moment, eg, conveyor belt which runs in straight line, as

the moment should be constant during the whole running process, it is recommended to

adopt straight-type V/F curve.

2. For the load featuring decreasing moment, eg, fan and water pump, as the relation

between its actual torque and speed is squared or cubed, it is recommended to adopt the V/F

curve corresponds to power 1.3, 1.7 or 2.0.

Output voltage

Output frequency

Straight-type

Torque -down V/F curve (1.3

th

order)

Square-type

Torque -down V/F curve (1.7

th

order)

Torque -down V/F curve (2.0

th

order)

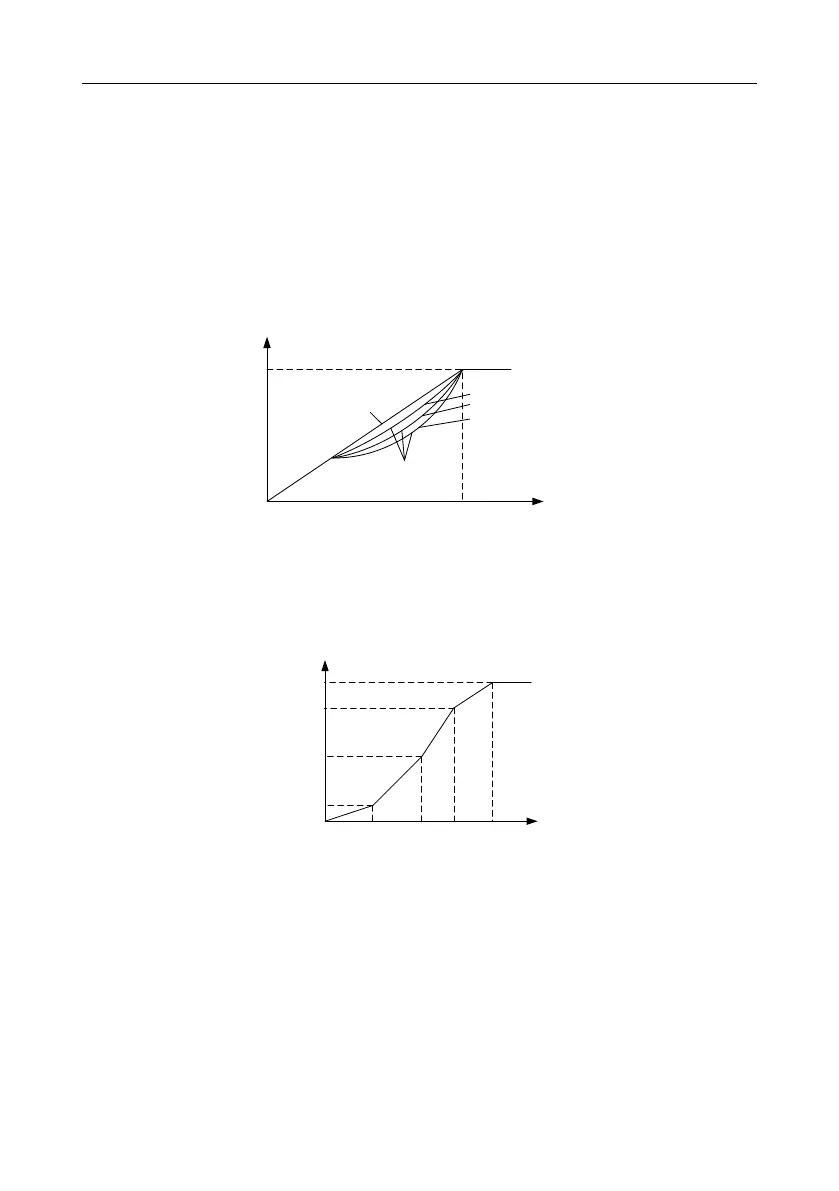

GD350 inverter also provides multi-point V/F curve. Users can alter the V/F curve outputted by

inverter through setting the voltage and frequency of the three points in the middle. The whole curve

consists of five points starting from (0Hz, 0V) and ending in (fundamental motor frequency, rated

motor voltage). During setup, it is required that 0≤f1≤f2≤f3≤fundamental motor frequency, and

0≤V1≤V2≤V3≤rated motor voltage

Output voltage

f1

f2

f3

V1

V2

V3

GD350 inverter provides dedicated function codes for SVPWM control mode. Users can improve the

performance of SVPWM through settings.

1. Torque boost

Torque boost function can effectively compensate for the low-speed torque performance during

SVPWM control. Automatic torque boost has been set by default to enable the inverter to adjust the

torque boost value based on actual load conditions.

Note:

(1) Torque boost is effective only under torque boost cut-off frequency;

Loading...

Loading...