117YLS-K

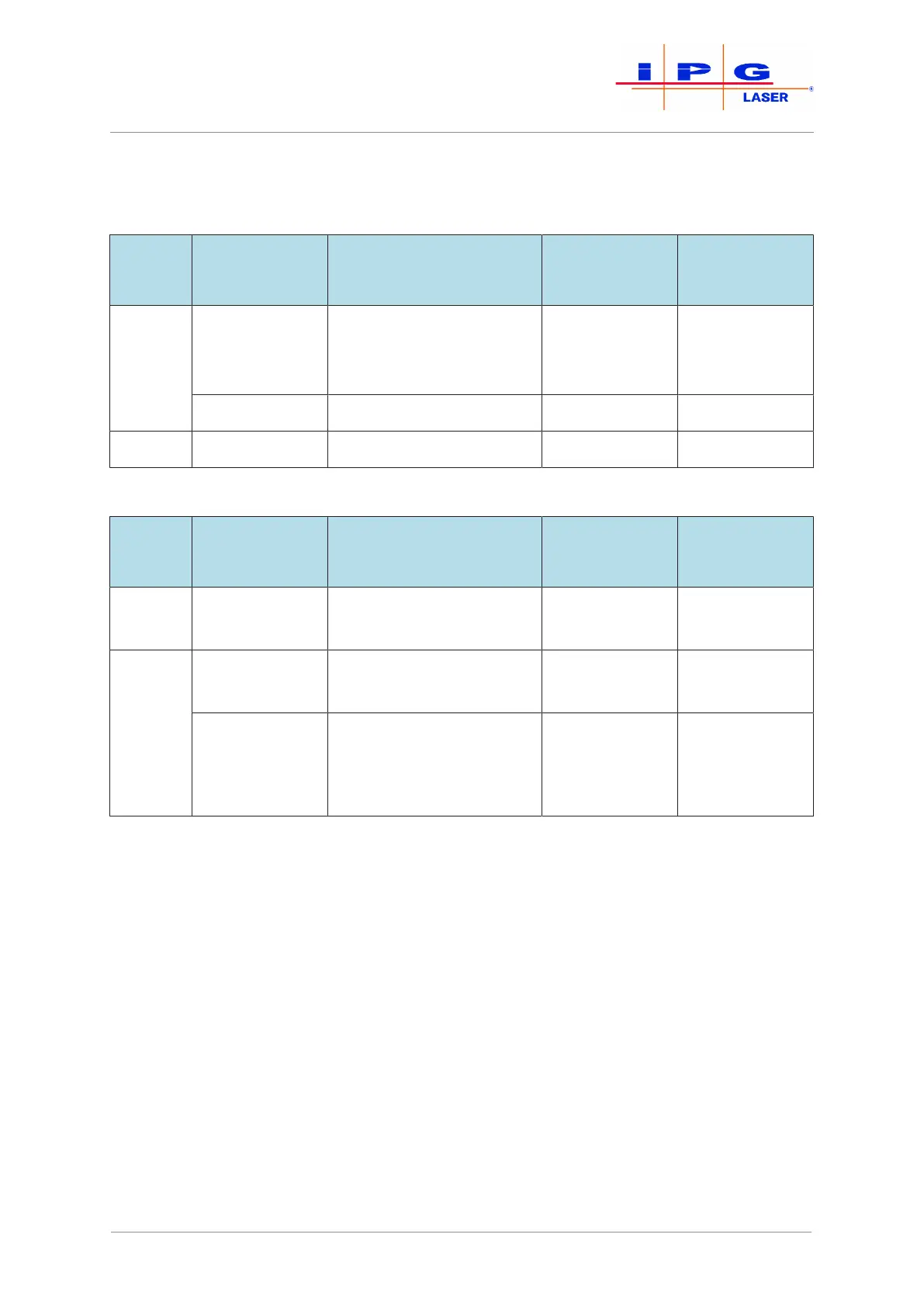

The following tables determine for which applications and usage condi-

tions the quartz block protection may be used.

Fiber

connec-

tor type

Use Operating conditions Process fiber

input

Process fiber

output / feed-

ing fiber

LC-8

HLC-8

All except cut-

ting

Low vibration

Acceleration < 5m/s²

Laser power < 6kW

Yes Yes

Cutting No restrictions Yes No

HLC-16 No restrictions No restrictions Yes Yes

Table19: Using the protective conduit

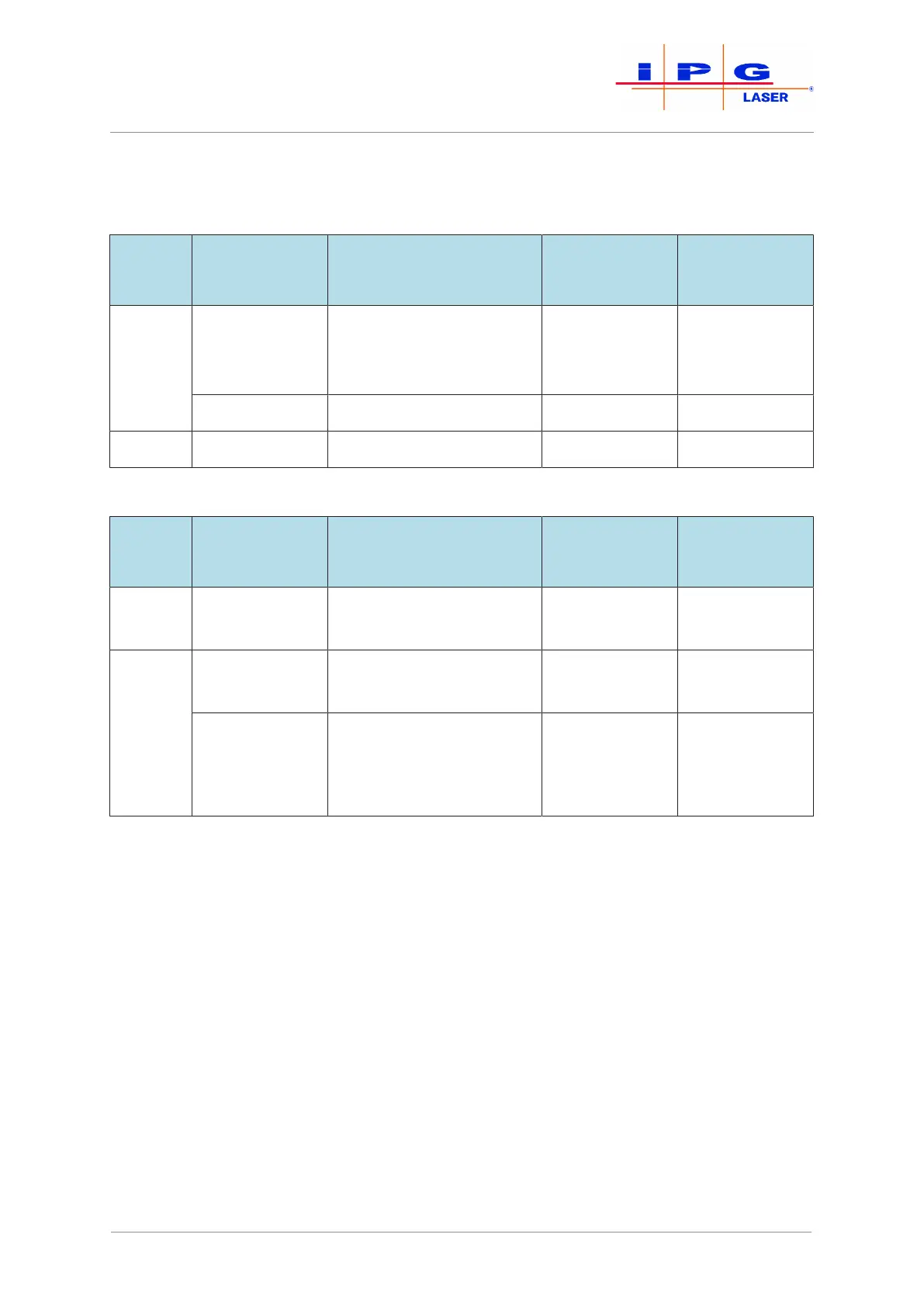

Fiber

connec-

tor type

Use Operating conditions Process fiber

input

Process fiber

output / feed-

ing fiber

HLC-8 No restrictions Laser power < 6 kW

Acceleration < 15 m/s²

No Yes

LCA

2D cutting Laser power < 6kW

Acceleration < 15 m/s²

Yes Yes

Everything ex-

cept 2D cutting

(3D cutting,

welding, etc.)

Laser power < 10 kW

Acceleration < 5 m/s²

Yes Yes

Table20: Using the protective glass

The cleaning steps differ depending on whether a protective conduit or

tube is used. For fiber connectors without quartz block protection or

with a protective conduit, the quartz-block end-face is cleaned; for fiber

connectors with protective glass, only the protective glass is cleaned, if

the quartz block end surface is free from debris. In case of persistent

dirt accumulation, the protective glass may be replaced with new pro-

tective glass.

Optional protective conduit

12. Remove the screwed-on protective conduit and place it on a clean

surface. A clean, lint-free cloth is ideal for placing the protective

conduit on.

13. Adjust the focus of the microscope to the quartz-block end-face.

| Maintenance

Loading...

Loading...