Dynamic-seal repeller replacement

This table shows the criteria for replacing dynamic-seal repeller parts for the 3196, CV 3196, and LF 3196

pump models.

Dynamic seal part When to replace

Dynamic-seal repeller vane The grooves are deeper than 1/16 in. (1.6 mm) or

are worn evenly more than 1/32 in. (0.8 mm).

Sleeve surface The surface has grooves, pitting, or other damage.

Labyrinth seal replacement

Replace the labyrinth-seal O-ring if it has cuts and cracks.

Gaskets, O-rings, and seats replacement

• Replace all gaskets and O-rings at each overhaul and disassembly.

• Inspect the seats. They must be smooth and free of physical defects.

In order to repair worn seats, skin cut them in a lathe while you maintain dimensional relationships

with other surfaces.

• Replace parts if the seats are defective.

Shaft and sleeve replacement guidelines

Two types of sleeves

The 3198 is offered with either a metallic sleeve that uses the standard 3196 shaft or a Teflon sleeve. The

Teflon sleeve requires a special shaft and a different inboard labyrinth oil seal.

Shaft measurements check

Replace the shaft (122) if any measurements exceed acceptable values. See Bearing fits and tolerances.

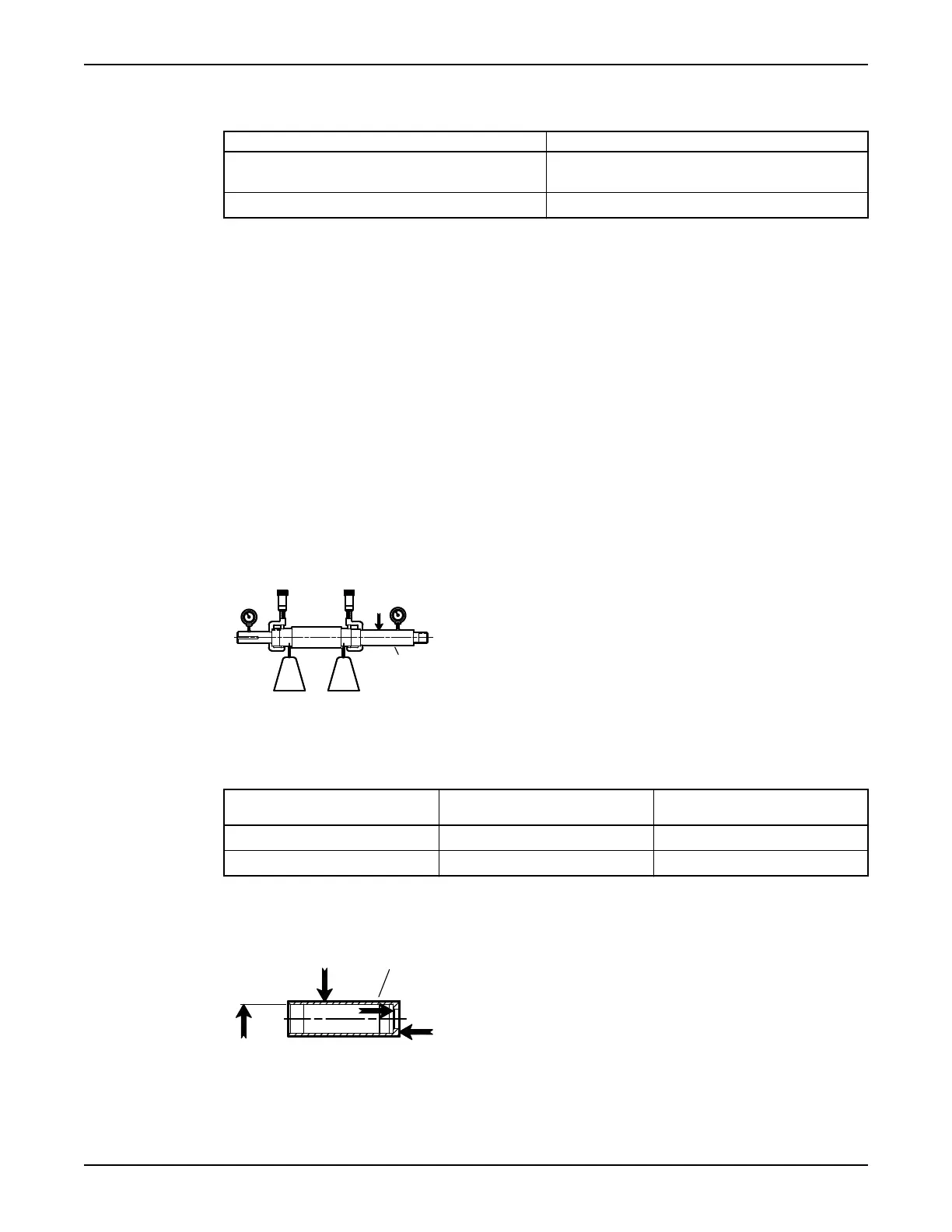

Straightness check

Replace the shaft (122) if runout exceeds the values in this table:

Table 13: Shaft runout tolerances for sleeve fit and coupling fit

Sleeve fit in inches

(millimeters)

Coupling fit in inches

(millimeters)

With sleeve 0.001 (0.025) 0.001 (0.025)

Without sleeve 0.002 (0.051) 0.001 (0.025)

Shaft and sleeve check

• Check the shaft and sleeve (126) surface for grooves and pitting.

• Replace the shaft and sleeve if any grooves or pits are found.

Maintenance

88 Model 3196 i-FRAME Installation, Operation, and Maintenance Manual

Loading...

Loading...