Model LJ Pool and Spa Heater

Page 11

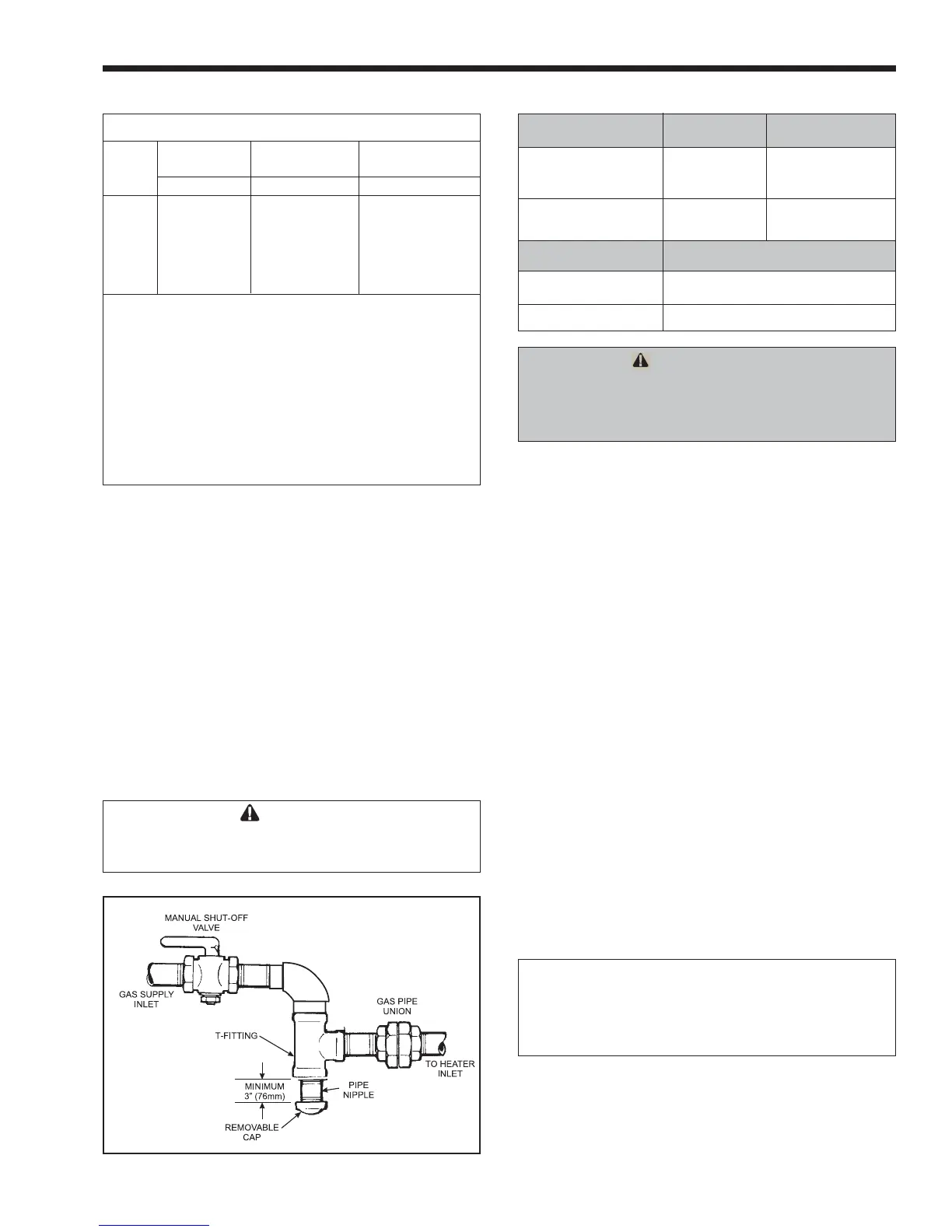

Figure 6. The proper design for a sediment trap / drip leg

plate. Jandy Lite2 LJ heaters, as shipped from

the factory, are certified to operate within the

altitude range indicated on the rating plate. If a

field conversion to a different altitude range

should be necessary, manifold kits are available

for changing the altitude range of the heater. See

Table 1 in section 1.7.1 of this manual to deter-

mine the correct altitude designation for your

heater. Refer to Section 11 “Parts List” to order

the correct part number of the manifold kit

needed. When changing the altitude range of the

heater, be sure to fill out the altitude conversion

label, included in the kit. Apply the label on the

inner panel of the heater, next to the original

rating plate.

CAUTION

Permanent damage to the gas valve will occur

if the following procedures are not followed.

ATTENTION

Vous endommagerez la soupape de gaz si

vous ne respectez pas les procédures

suivantes.

3. Use the figures in Table 4 to size the gas inlet

piping from the gas meter to the heater. Check

all local codes for compliance before installing

the heater.

Table 4. Natural Gas Pipe Size Requirements

Distance from Gas Meter

0-50 feet 50-100 feet 100-200 feet

Heater (0-15 m) (15-30 m) (30-60 m)

Size in. (mm) in. (mm) in. (mm)

125 3/4 (19) 1 (25) 1 (25)

175 1 (25) 1 (25) 1-1/4 (32)

250 1 (25) 1-1/4 (32) 1-1/4 (32)

325 1-1/4 (32) 1-1/4 (32) 1-1/2 (38)

400 1-1/4 (32) 1-1/2 (38) 1-1/2 (38)

Notes:

1. These numbers are for natural gas (0.65 Sp. Gr.) and are

based on 1/2 inch (13mm) water column pressure drop.

Check supply pressure with a manometer, and local code

requirements for variations. For liquefied petroleum gas,

reduce pipe diameter one size, but maintain a 3/4 inch

(19mm) minimum diameter.

2. Check supply pressure and local code requirements

before proceeding with work.

3. Pipe fittings must be considered when determining gas

pipe sizing.

Supply Pressure Minimum Maximum

Natural Gas 5.5 Inches WC 10.0 Inches WC

(1.4 kPa) (2.5 kPa)

LP Gas 10.0 Inches WC 14.0 Inches WC

(2.5 kPa) (3.5 kPa)

Manifold Pressure Nominal

Natural Gas 4.0 Inches WC (1.0 kPa)

LP Gas 9.0 Inches WC (2.2 kPa)

Table 5. Gas Supply Pressure Requirements

4. Install a sediment trap (drip leg) ahead of the gas

controls (see Figure 6). Fit the trap with a

threaded cap which can be removed for cleaning.

5. Install a manual gas shutoff valve for service and

safety. Do not use a restrictive gas cock. DO

NOT USE FLEXIBLE GAS PIPING, it will

restrict the gas flow to the heater.

6. Disconnect the heater and its individual shutoff

valve from the gas supply system during pressure

testing of the system at pressures higher than 1/2

pounds per square inch (psi) (3.45 kilopascals

[kPa]). If the test pressure is equal to or less

than 1/2 psi (3.45 kPa), close the manual shutoff

valve on the heater during the piping pressure

test.

7. If the gas supply pressure is less than required,

check for undersized pipe between the meter and

the heater, a restrictive fitting, or an undersized

gas meter. Gas supply pressures to the heater

are listed in Table 5.

NOTE: The maximum inlet gas pressure must

not exceed the specified value. The minimum

value listed is for the purpose of input

adjustment. Refer to Table 5.

8. Before operating the heater, test the complete

gas supply system and all connections for leaks

using a soap solution. Do not use an open flame.

Loading...

Loading...