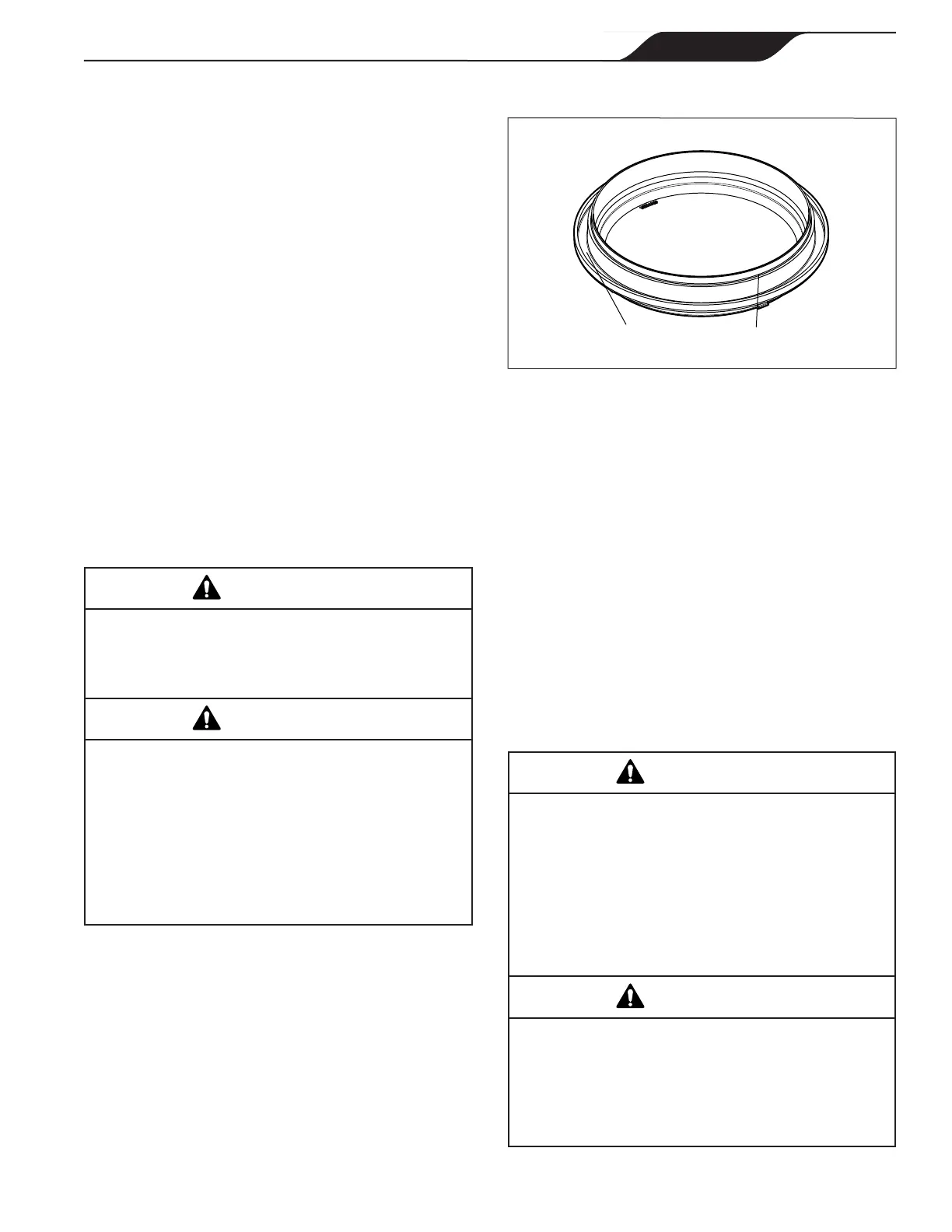

2. Place the blue o-ring on the step located ¼"

from the bottom of the lid. See Figure 5.

Figure 5. Placement of Blue Pressure Test O-ring

Upside Down View of Bottom of Lid

Step where

O-ring is Seated

Groove where

Seal is Seated

3. Make sure that the o-ring is properly seated. It

helps to “place” the o-ring on the step rather

than to “roll” it on. That prevents it from rolling

off.

NOTE The blue o-ring sits approximately ¼" away from the

seal. See Figure 5.

4. Carefully install the lid, making sure that the

blue pressure test o-ring sits in the housing

without “binding” or “rolling” off.

5. Following the markings on the locking ring,

align ‘START’ markings with the ports and

turn clockwise until ‘LOCKED’ markings

align with the ports. Do not tighten past the

‘LOCKED’ marking.

3.3.1.3 Conduct Pressure Test

When pressure testing a system with water, air

isoftentrappedinthesystemduringthelling

process. This air will compress when the system is

pressurized. Should the system fail, this trapped air

can propel debris at a high speed and cause injury.

Every effort to remove trapped air must be taken,

includingopeningthebleedvalveonthelterand

looseningthepumpbasketlidonthelterpump

whilellingthepump.

WARNING

Trappedairinsystemcancauselterlidtobe

blown off, which can result in death, serious per-

sonal injury, or property damage. Be sure all air is

properly out of system before operating. DO NOT

USE COMPRESSED AIR TO PRESSURE TEST

OR CHECK FOR LEAKS.

WARNING

3.3.1 Replace Blue Pressure Test O-ring if

Necessary

If you open the pump lid before conducting the pressure

test, the blue o-ring may fall out. If this happens, you

will need to install it on the lid again before conducting

pressure testing.

There is a risk of damage to the blue o-ring during re-

installation. If you damage it when trying to re-install

it, you will need to order a new blue pressure test o-ring

(R0479000) before you begin conducting the pressure

test.

These instructions describe the proper procedures for

replacing, using, and disposing of the blue o-ring.

These instructions must be followed exactly. Read

through the instructions completely before starting

the procedure.

3.3.1.1 Remove Pump Lid

1. Make sure that the pump is turned off.

2. Make sure that the switch to the circuit breaker

that powers the pump motor is turned off.

Turn off the pump and the main breaker in the

pump electrical circuit before starting the procedure.

Failure to comply may cause a shock hazard,

resulting in severe personal injury or death.

WARNING

Duetothepotentialriskofre,electricshock,or

injuries to persons, Jandy Pumps must be installed

in accordance with the National Electrical Code

®

(NEC

®

),intheUSA,ortheCanadianElectrical

Code (CEC

®

)inCanada.Allapplicablelocalcodes

must also be followed.

The NEC may be obtained by contacting the

National Fire Protection Association

®

(NFPA

®

)at

1-800-344-3555 or 1-617-770-3000.

WARNING

3. Make sure all necessary isolation valves are

closed to prevent pool water from reaching the

pump.

4. Following the markings on the locking ring,

turn the ring counter-clockwise until the

‘START’ markings align with the ports.

5. Carefully remove the lid with locking ring.

3.3.1.2 Replace Blue O-ring

1. Turn the lid with locking ring upside down and

place it on a stable surface.

Page 11

ENGLISH

Jandy

®

Stealth

™

Pumps

|

Operation Manual

Loading...

Loading...