12 - 8

Fault Finding

up to machine no. 751011

Machine moves when drive control is in neutral.

This may be caused by the neutral setting of the pump being

incorrect but before assuming this check that the joystick

spools are not sticking and are being correctly operated by

the joystick lever.

!!

WARNING

The following procedure requires the machine to be

disabled (wheels raised off the ground, work function

disconnected etc.) while the work is carried out.

HYD 8-1/1

Place the machine safely onto blocks, so that all four wheels

are clear of the ground. Ensure that the machine is stable.

Position the operator’s seat facing forwards so that the

brakes are released.

Start engine and note which pair of wheels is turning. This

will indicate which pump is not returning to neutral. Note

that pump P1 (nearest the engine) feeds the left hand motors

and pump P2 the right hand motors.

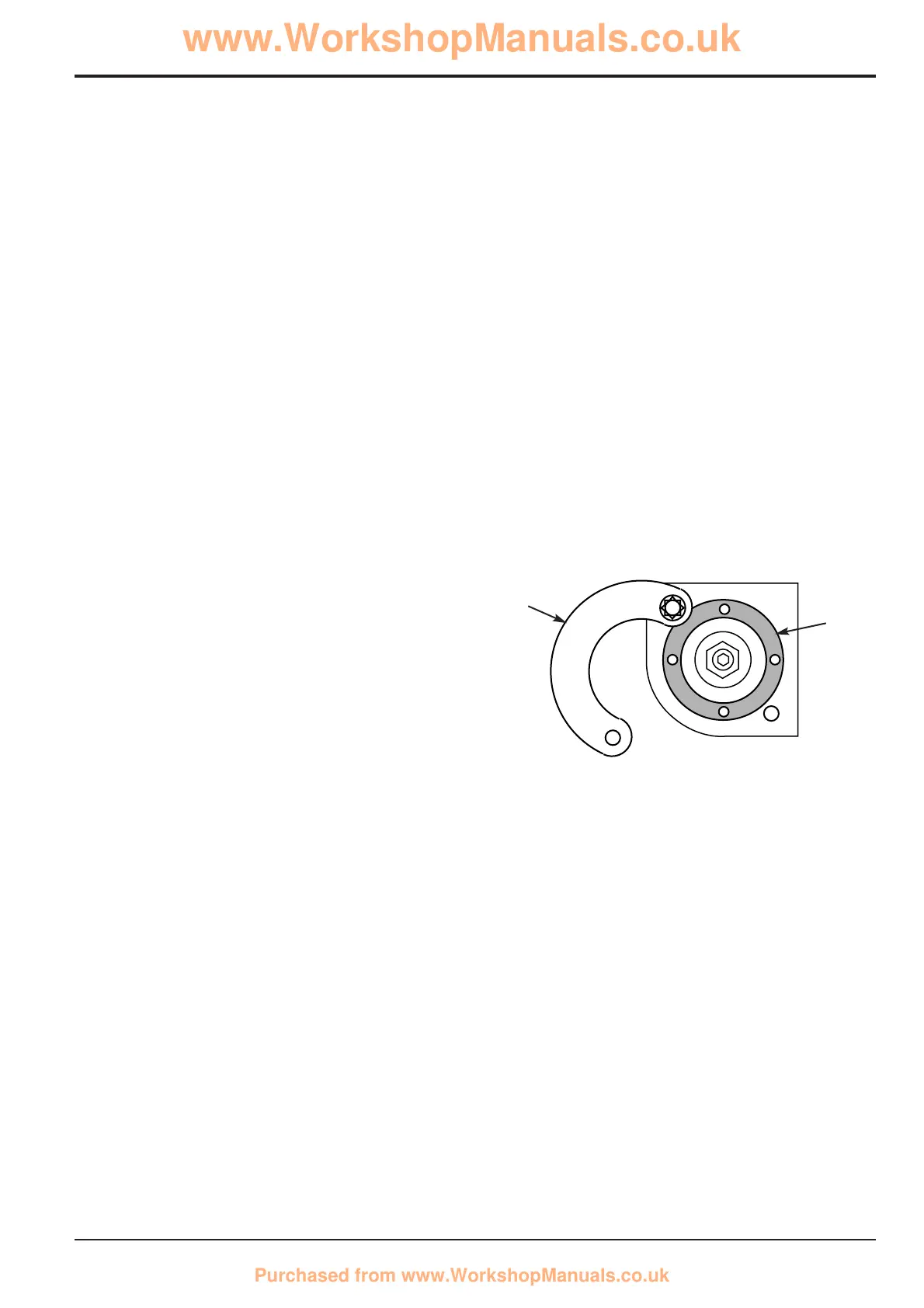

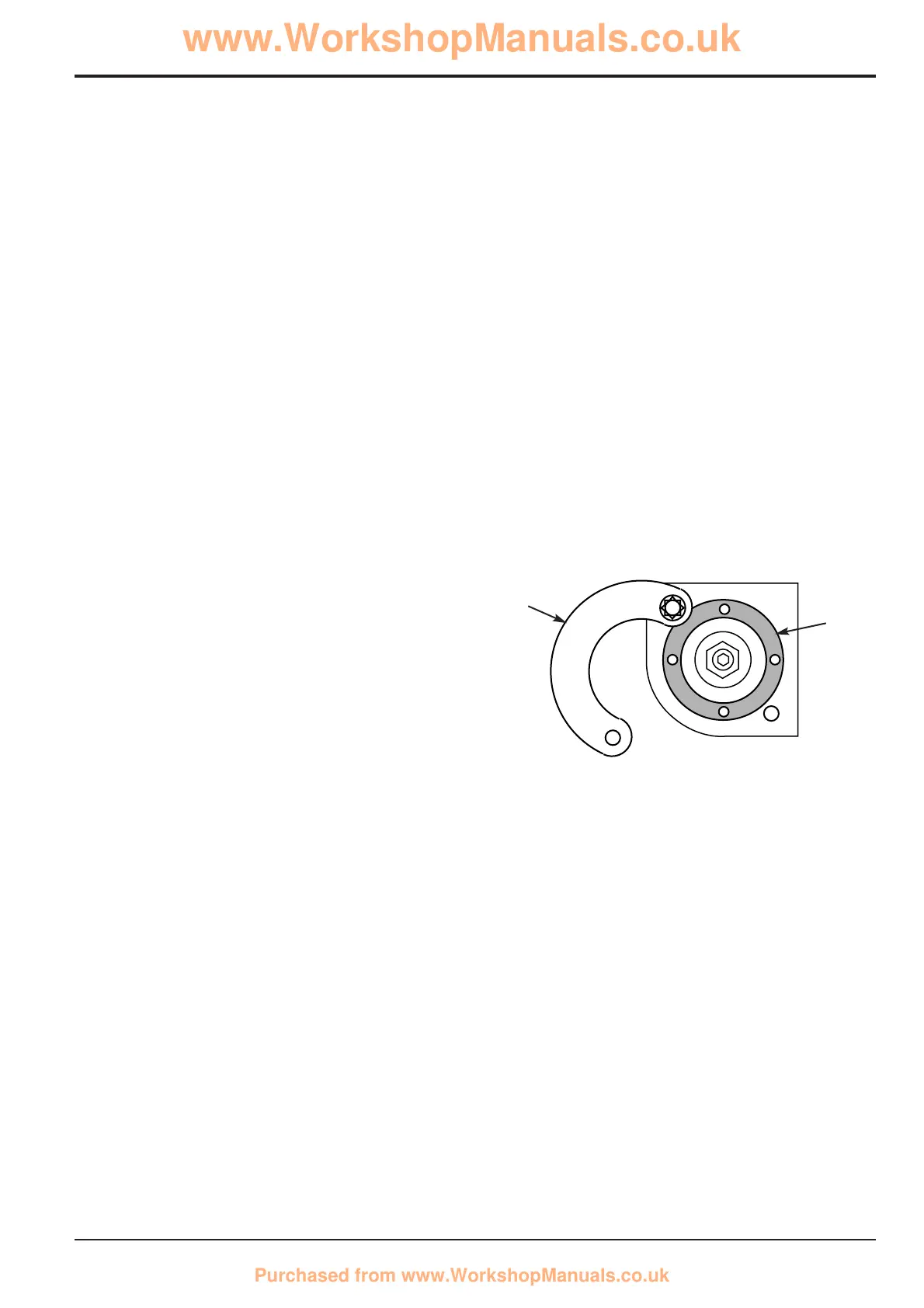

The neutral adjustment can be made by rotating the outer

adjustment ring E on each pair of servo units. Note that any

adjustment to one servo unit must be countered by an equal

adjustment, in the opposite direction, of the other servo unit

of the same pump.

Travel Speed

The maximum speed of the machine should be checked

following the above adjustments. This involves raising the

machine off the ground and checking the wheel speeds

using a stroboscopic meter.

Note that excessive wheel speed may result in cooling

problems as the hydraulic oil may overheat.

!!

WARNING

The following procedure requires the machine to be

disabled (wheels raised off the ground, work function

disconnected etc.) while the work is carried out.

HYD 8-1/1

Place the machine safely onto blocks, so that all four wheels

are clear of the ground. Ensure that the machine is stable.

Position the operator’s seat facing forwards so that the

brakes are released.

Remove one locking plate screw and slacken the other

screw then swing the locking plate F clear. Adjust as

outlined in the following table. Refer to illustration on

previous page.

Wheel Movement Servo units to be adjusted

R. H. forwards Screw B out and A in

R. H. backwards Screw A out and B in

L. H. forwards Screw C out and D in

L. H. backwards Screw D out and C in

Turn each adjustment ring E one quarter turn at a time and

recheck wheel movement. Always turn one adjustment ring

out before turning the opposite ring in.

When adjustment is complete, re-assemble locking plates

and re-stake.

Stick a piece of reflective tape on a wheel rim. Start the

engine and run at maximum speed then operate the drive

control. Measure the speed of wheel rotation in each

direction which should be 81 rev/min. An allowance of 2%

above this figure is permissible. Check the speed of the

wheels on the opposite side of the machine.

If necessary the appropriate adjusting screws should be

screwed in

1

/2

turn at a time until the correct wheel speed is

achieved. Stop the engine while adjustment is carried out.

If the left hand wheels are rotating too fast screw in

adjusters C and A (see illustration on previous page). Both

adjusters must be turned by equal amounts to maintain

straight line travel.

If the right hand wheels are rotating too fast screw in

adjusters D and B by equal amounts.

Section E Hydraulics

9803/8550

Section E

12 - 8

Issue 1

Pumps

E

F

Loading...

Loading...