Section E Hydraulics

9803/8550

Section E

Pumps

12 - 11

Hydrostatic Pump

from machine no. 751012

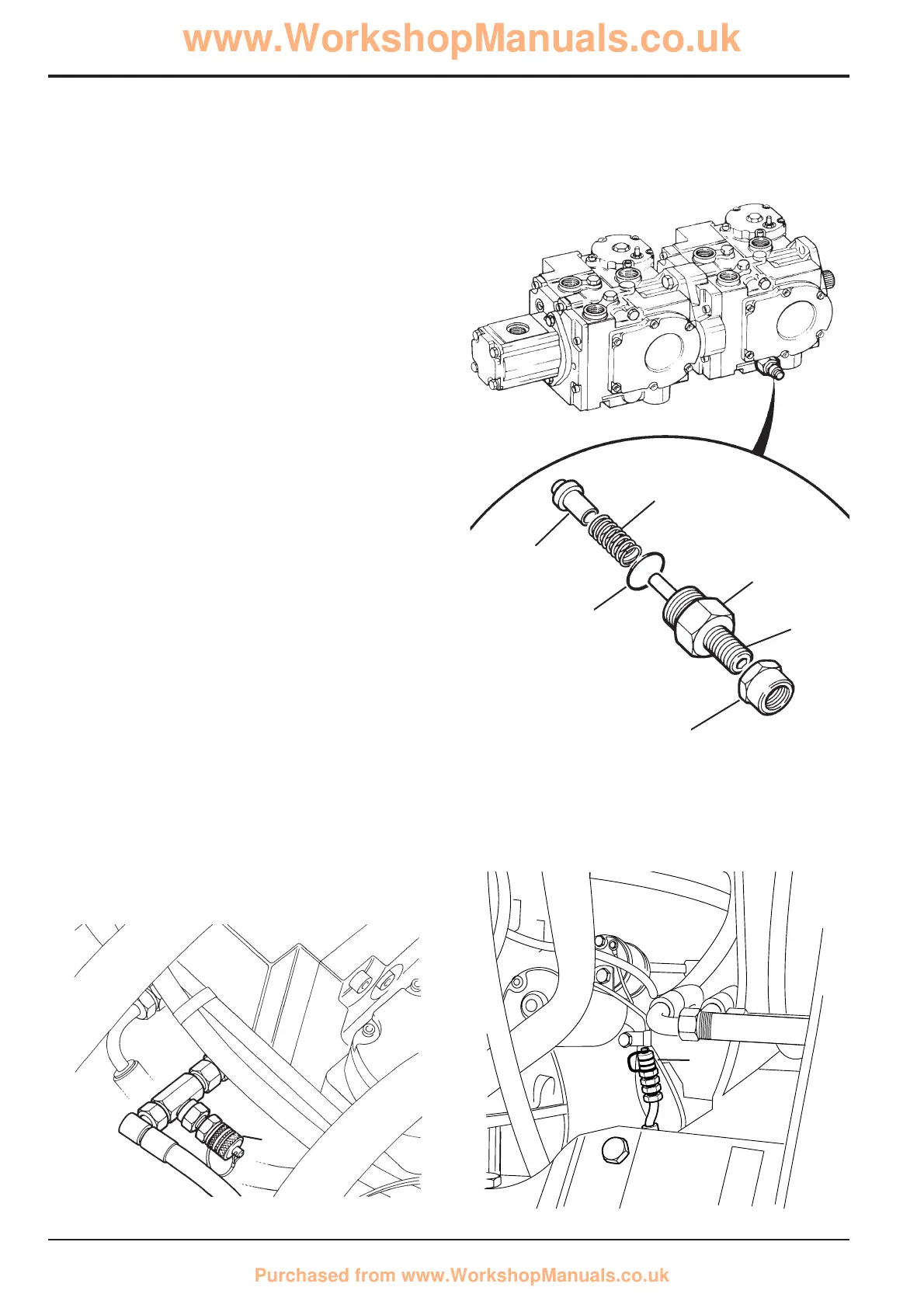

Charge/Anti-stall Valve

Dismantling and Assembly

1 Mark the plug 1, locknut 2 and the pump body so as to

approximately maintain the original adjustment.

2 Loosen locknut 2 and unscrew plug 1 from pump body.

Remove O-ring 3 from plug 1 and discard O-ring.

3 Remove spring 4 and poppet 5 from pump body.

4 Inspect poppet 5 and mating seat in pump body for

damage. Renew as necessary.

5 Install a new O-ring 3 on plug 1.

6 Fit poppet 5 and spring 4 into pump body.

7 Screw plug 1 complete with locknut 2 into pump body

to align with the marks made during disassembly.

Tighten the locknut.

8 Check the charge pressure and adjust as necessary.

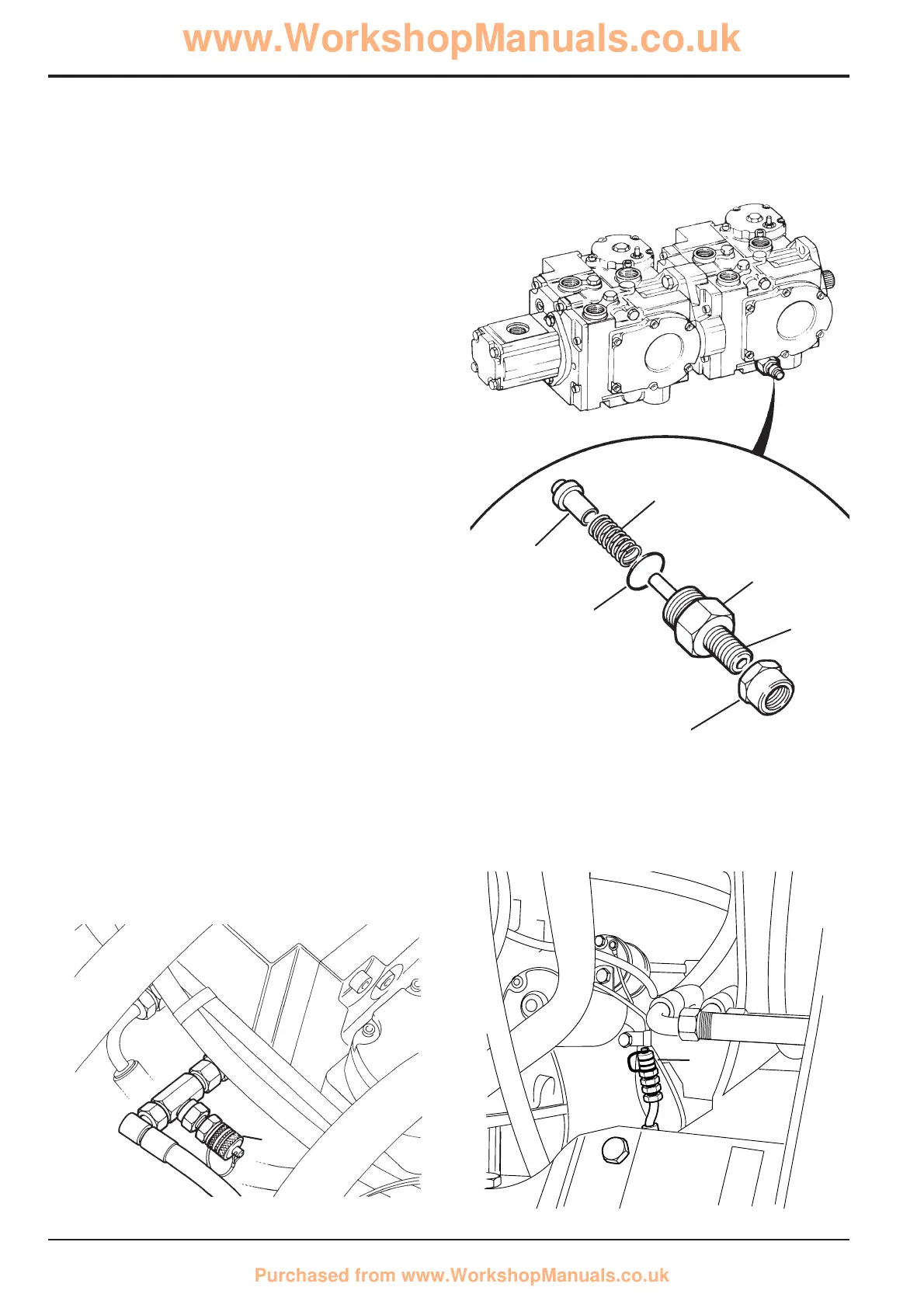

Charge Pressure Checking and Adjustment

1 Stop engine. Connect a 0 - 40 bar (0 - 600 lb/in

2

, 0 - 42

kg/cm

2

) pressure gauge into the test point which up to

machine no. 751715 is situated underneath the pump

as shown at X. From serial no. 751716 the test point is

positioned at the rear of the left hand side of the engine

as shown at Y.

2 Start engine and check pressure is as specified in

Technical Data.

3 If the pressure is not as specified, stop the engine.

Unscrew locknut 2 and turn adjuster Z

1

/4 turn at a time

(clockwise to increase pressure) then re-tighten

locknut. Start engine and re-check pressure. Continue

procedure until pressure is correct then remove

pressure gauge.

12 - 11

Issue 3*

S244920

4

3

2

5

1

Z

S246240

X

*

348890

Y

Loading...

Loading...