Assembly

The assembly procedure is the reverse of the dismantling

procedure.

Make sure all components are thoroughly clean prior to

assembly. Renew all 'O' rings.

1 Lubricate the piston 21 with hydraulic oil and press fully

into bore of clutch housing.

2 Fit oil baffle 20, spring 19 and spring retaining plate 18.

3 Compress spring and fit circlip 17.

4 Fit the disc spring assembly 16 and the thin pressure

plate (4mm thick) 13A.

5 Fit counter plates 15 and friction plates 14 alternately,

starting with a counter plate.

6 Fit the thick pressure end plate (6mm thick) 13 and

clutch friction/counter plate retaining circlip 11.

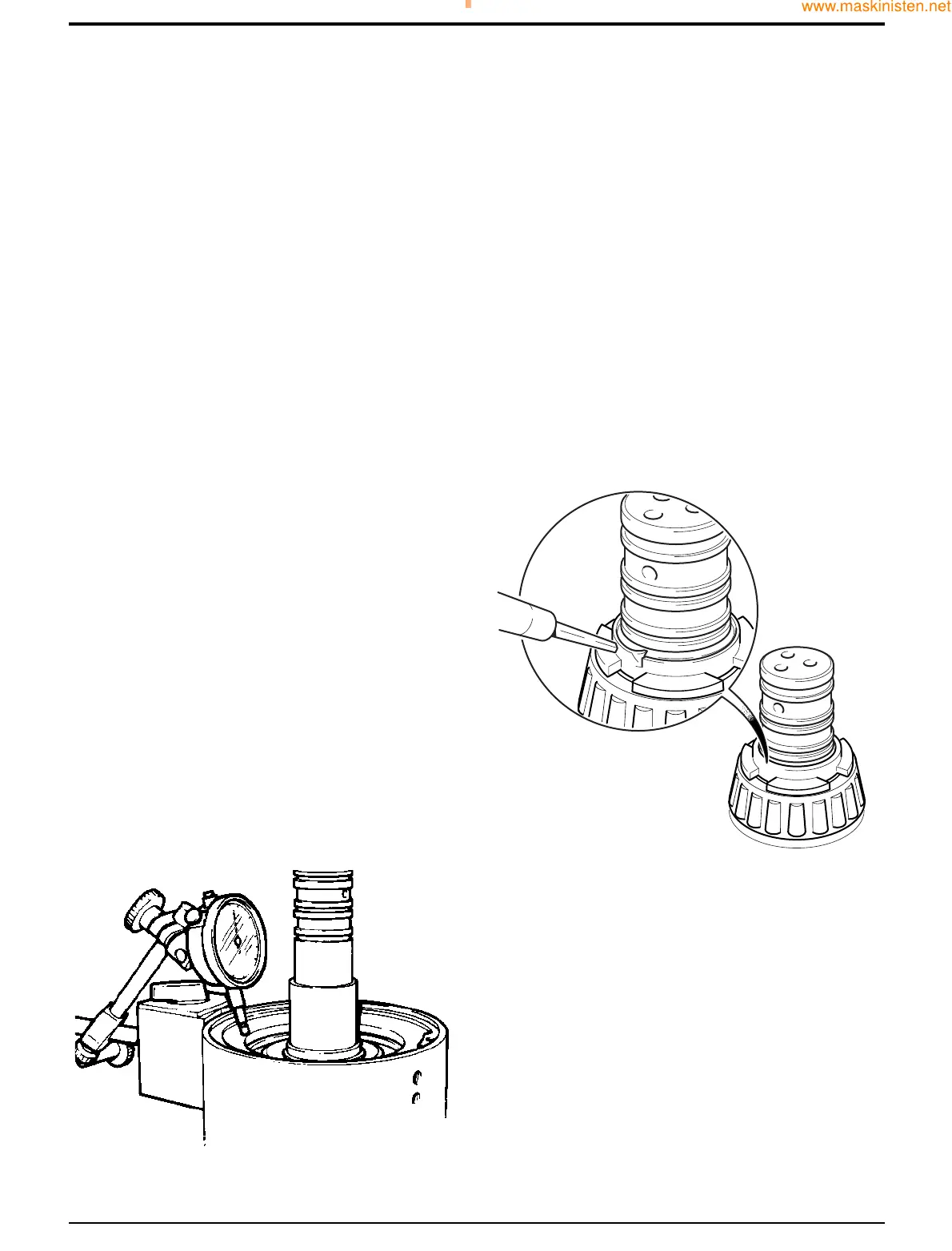

7 Using a dial test indicator as shown at A, measure the

end float of the pressure end plate 13, which should be

2.0 to 3.3 mm (0.079 to 0.130 in). If the float is above

3.3mm (0.130 in), fit shim 12 between the retaining

circlip and pressure end plate to bring end float within

tolerance. If the float is below 2.0 mm (0.079 in),

remove the thin pressure plate (4mm thick) 17 at piston

end and replace with a counter plate 13, then shim as

necessary to bring end float within tolerance.

8 Fit thrust washers 10 and 8 and thrust bearing 9.

9 Carefully align teeth of clutch plates using a thin rod or

screwdriver. Fit gear and splined hub assembly 6.

10 Fit needle roller bearing 7, thrust washers 5 and 3 and

thrust bearing 4.

62 - 4

11 Pack the clutch end bearing with JCB MPL Grease and

press the bearing onto clutch shaft.

12 Fit a new stake nut 1A and torque tighten to 200 Nm

(147.5 lbf ft).

Note: To tighten the nut locate the clutch assembly into the

holding fixture (service tool 892/01065) as shown in

dismantling and use the adaptor spanner (service tool

892/01064) and a 1/2” square drive torque wrench.

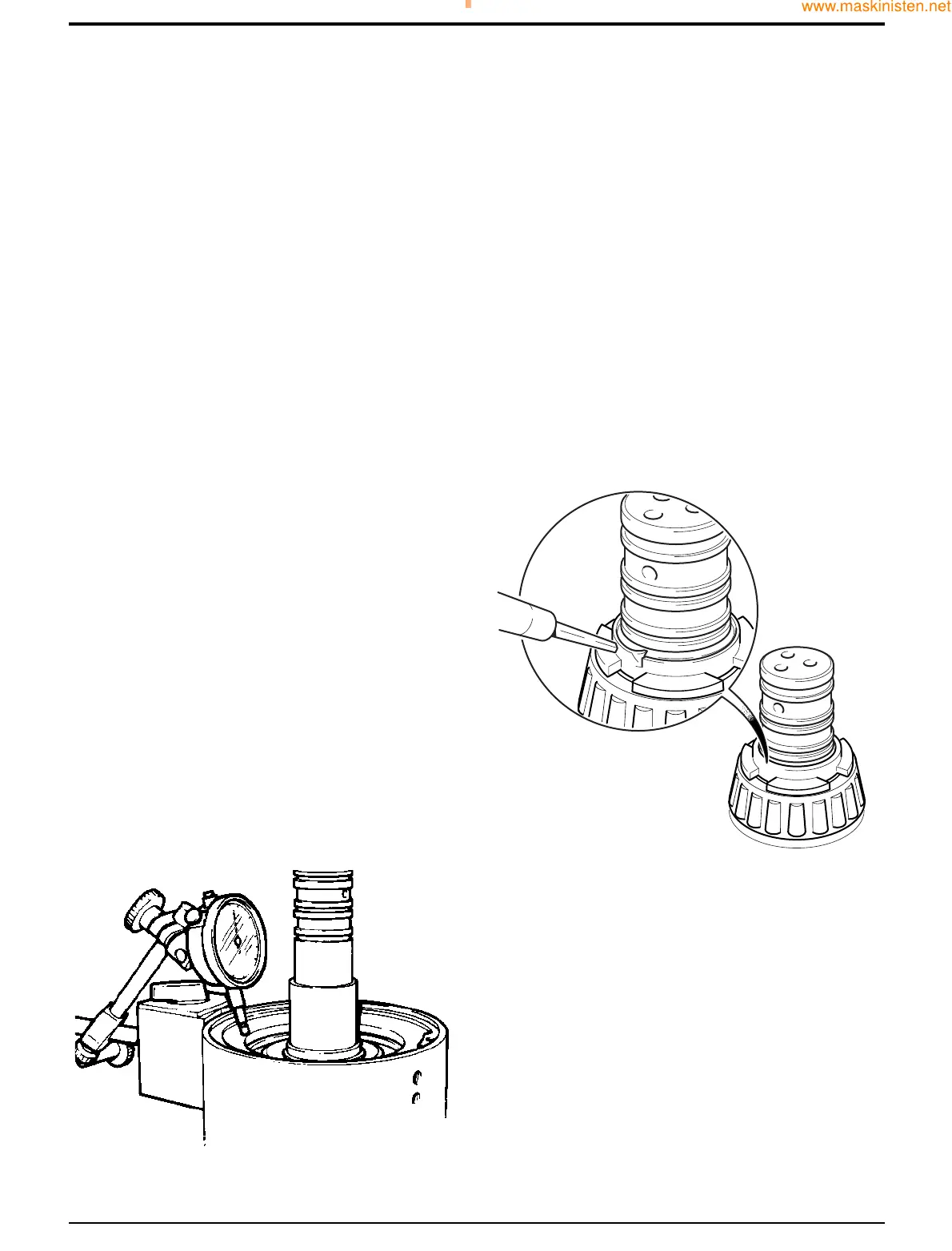

13 Re-stake the nut using a square ended staking tool as

shown at B.

14 Fit piston ring seals.

15 Assemble the opposite clutch assembly (torque

converter end) by repeating steps 1 to 14.

Section F Transmission

9803/7130

Section F

62 - 4

Issue 1

Reverser Unit

S191420

Loading...

Loading...