114

JOHNSON CONTROLS

FORM 145.05-NOM1 708)

Coil Pressure Drop (FlexSys Units Only)

On FlexSys units a transducer is used to monitor the

pressure drop across the evaporator coil. This pressure

drop is used to verify supply fan operation and also used

to control the by pass damper to prevent excessive by

pass air resulting in the frosting of the evaporator coil.

The transducer is factory wired and tubing attached and

located on either side of the evaporator coil.

When verifying transducer operation, the technician

must insert a tee in each of the tubes connected to the

transducer to verify the differential pressure being

applied to the transducer. Once this pressure is known, a

comparison can be made of the duct pressure vs. output

milliamp values from the transducer. To check the

milliamp output from the transducer remove the wire

from the output (OUT) connection on the transducer and

connect your meter between the end of the wire and the

(OUT) terminal of the transducer. Table 24 shows the

relationship between the pressure applied to the duct

static pressure transducer and the output voltage. The

output is linear.

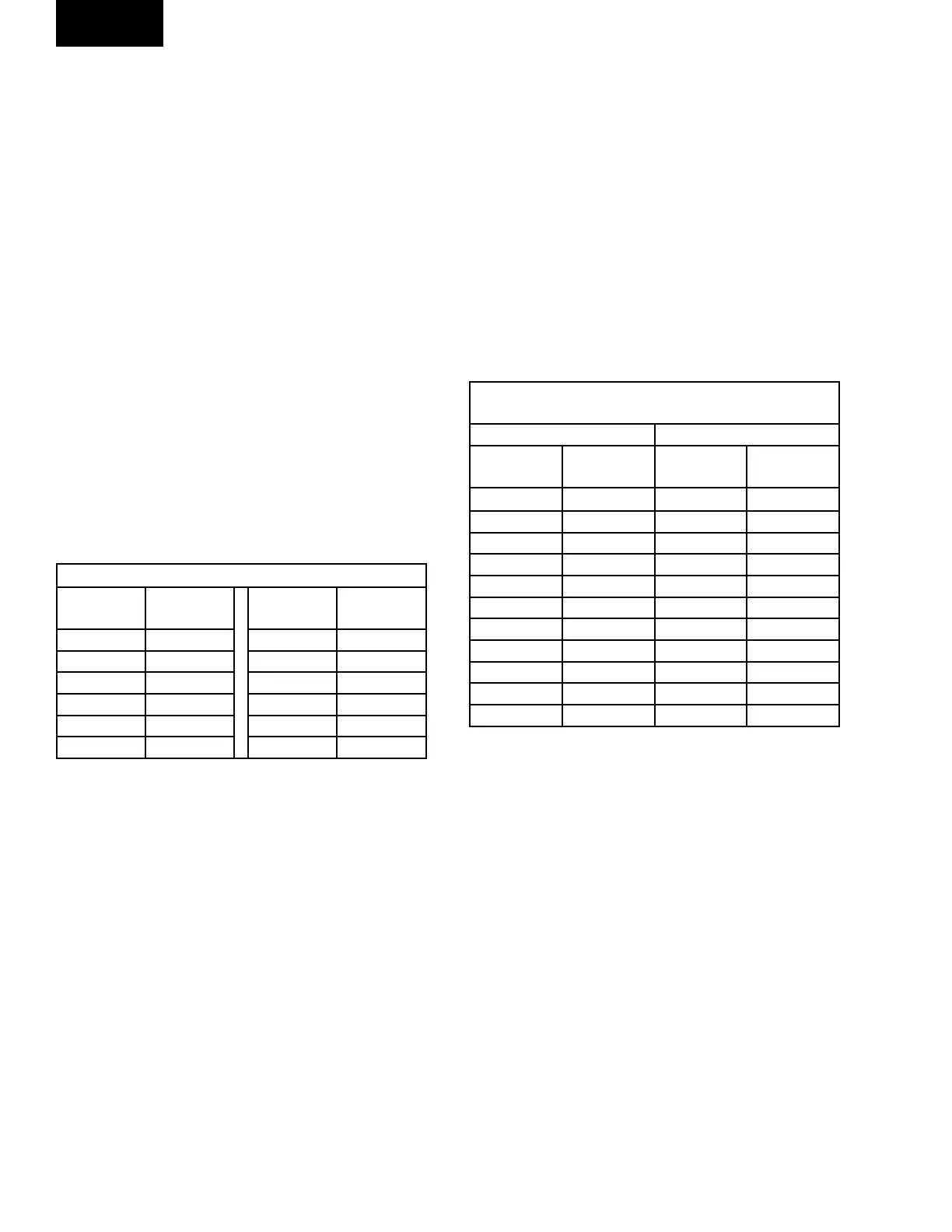

TABLE 24 – COIL PRESSURE DROP (FLEXSYS)

DIFF PRESS

(IN WC)

MA

OUTPUT

DIFF PRESS

(IN WC)

MA

OUTPUT

0.0 4.0 1.5 13.6

0.25 5.6 1.75 15.2

0.50 7.2 2.0 16.8

0.75 8.8 2.25 18.4

1.0 10.4 2.5 20.0

1.25 12.0

Discharge Pressure Transducer

A discharge pressure transducer is located on each of the

discharge lines leaving the compressors. The purpose

of the transducer is to sense and convert the discharge

pressure into a DC voltage. The DC voltage is then

sent to the Unit Control where it is used to control the

condenser water valve. The discharge pressure value,

in psig, is displayed by the User Interface.

The discharge transducer has a range of 0 to 400 psig,

with a linear output of 0 to 5 DC volts. Table 25

illustrates the DC volt output from the transducer for a

given discharge pressure.

Suction Pressure Transducer

A suction pressure transducer is located on each of the

suction lines entering the compressor. The purpose

of the transducer is to sense and convert the suction

pressure into a DC voltage. The DC voltage is then

sent to the Unit Control where it is used to verify proper

low side pressure. The suction pressure value, in psig,

is displayed by the User Interface.

The suction pressure transducer has a range of 0 to 150

psig, with a linear output of 0 to 5 volts DC. Table 25

illustrates the DC voltage output from the transducer

for a given suction pressure.

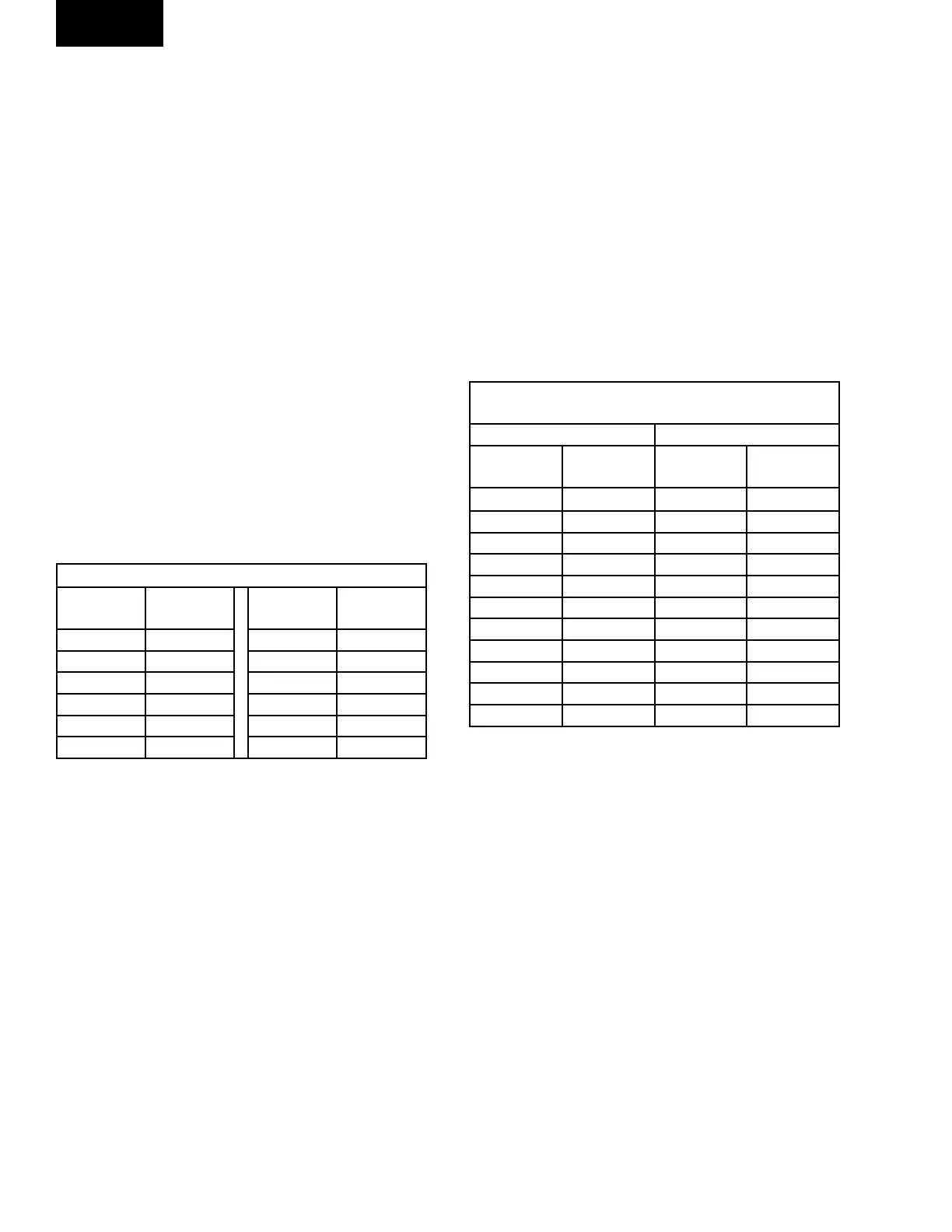

TABLE 25 – REFRIGERANT PRESSURE

TRANSDUCERS

SUCTION TRANSDUCER DISCHARGE TRANSDUCER

PRESSURE

PSIG

VOLTAGE

VDC

PRESSURE

PSIG

VOLTAGE

VDC

0 0.50 0 0.50

15 0.90 50 1.0

30 1.3 100 1.5

45 1.7 150 2.0

60 2.1 200 2.5

75 2.5 250 3.0

90 2.9 300 3.5

105 3.3 350 4.0

120 3.70 400 4.5

135 4.1

150 4.5

Humidity Sensor (FlexSys Units Only)

The humidity sensor outputs a 4 to 20 milliamp output

in response the relative humidity level of the supply

air. This value is used to determine the dew point of

the supply air entering the under floor space. The Unit

Control adjusts the supply air dew point to keep the

dew point temperature below the slab temperature of

the under floor area.

Service

Loading...

Loading...