F 5

0708.GB

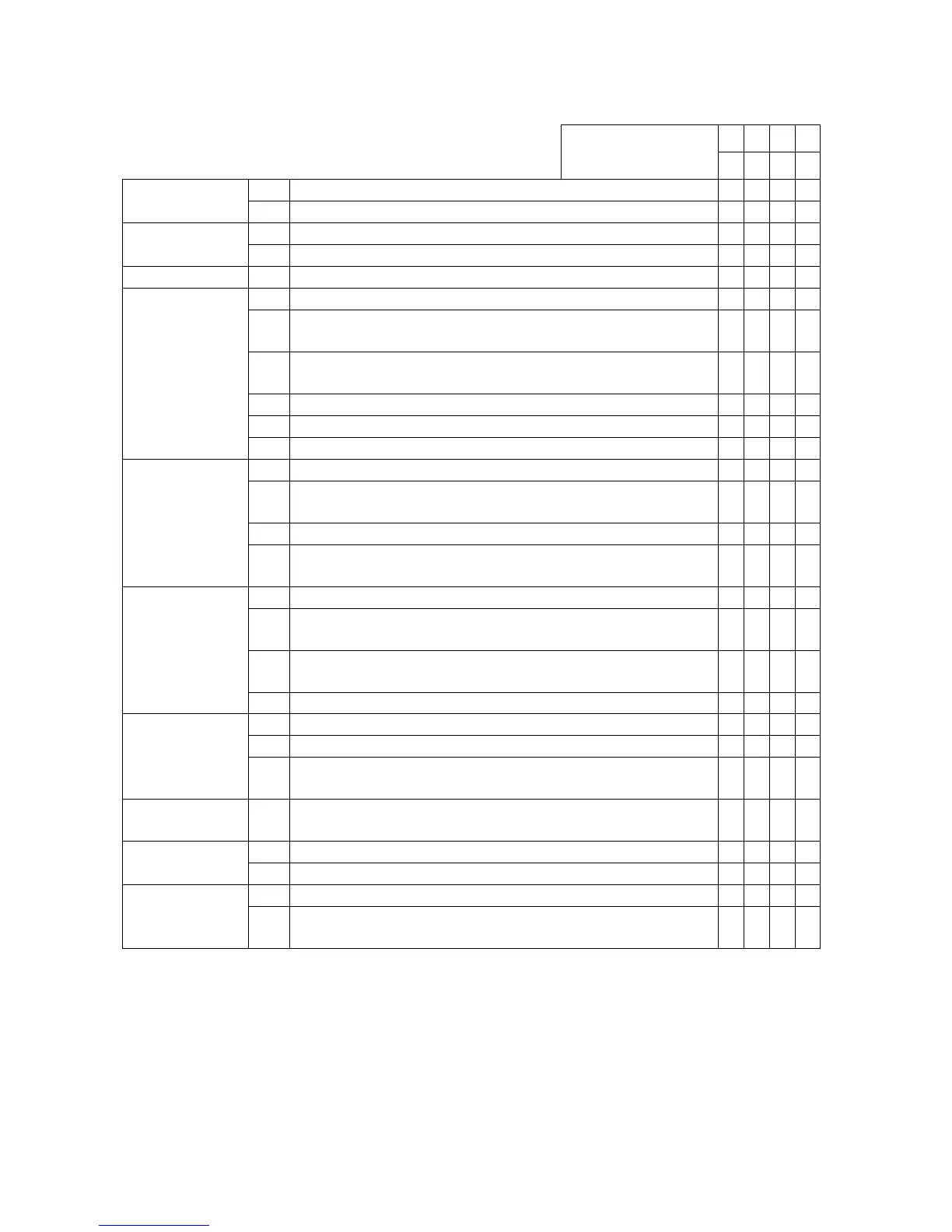

5 AMX-E Maintenance Checklist:

Maintenance intervals

Standard =

t

WA B C

Cold Store =

k

Chassis/

Design:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

Wheels: 2.1 Check wheels for wear and damage t

2.2 Check suspension and attachment t

Steering: 3.1 Check the steering play t

Hydraulic

System:

5.1 Test operation t

5.2 Check unions and connections for leaks and

and check damage

t

5.3 Make sure hydraulic unit is sealed, check for damage

and test attachment

t

5.4 Check oil level t

5.5 Replace hydraulic oil and filter cartridge t

5.6 Test pressure relief valves t

Electrical

System:

6.1 Test operation t

6.2 Check all cables are secure and check for damage t

6.3 Check fuse ratings t

6.4 Make sure switches are secure and are operating

correctly

t

Battery: 7.1 Check acid density, acid level and cell voltage t

7.2 Check terminals are securely attached, and apply

grease

t

7.3 Clean battery plug connections,

make sure they are tight

t

7.4 Check battery cables for damage, replace if necessary. t

Lift

mechanism:

8.1 Check operation, wear and setting t

8.2 Check the load wheels and plunger rods t

8.3 Check forks and fork carriage for wear and

damage

t

Lubrication: 9.1 Lubricate truck in accordance with Lubrication

Schedule.

t

General

Measurements:

10.1 Check electrical system for frame leakage t

10.3 Test lift and lowering speeds t

Demonstration: 11.1 Test run with rated load t

11.2 After completing maintenance, present the truck to

the supervisor

t

F 5

0708.GB

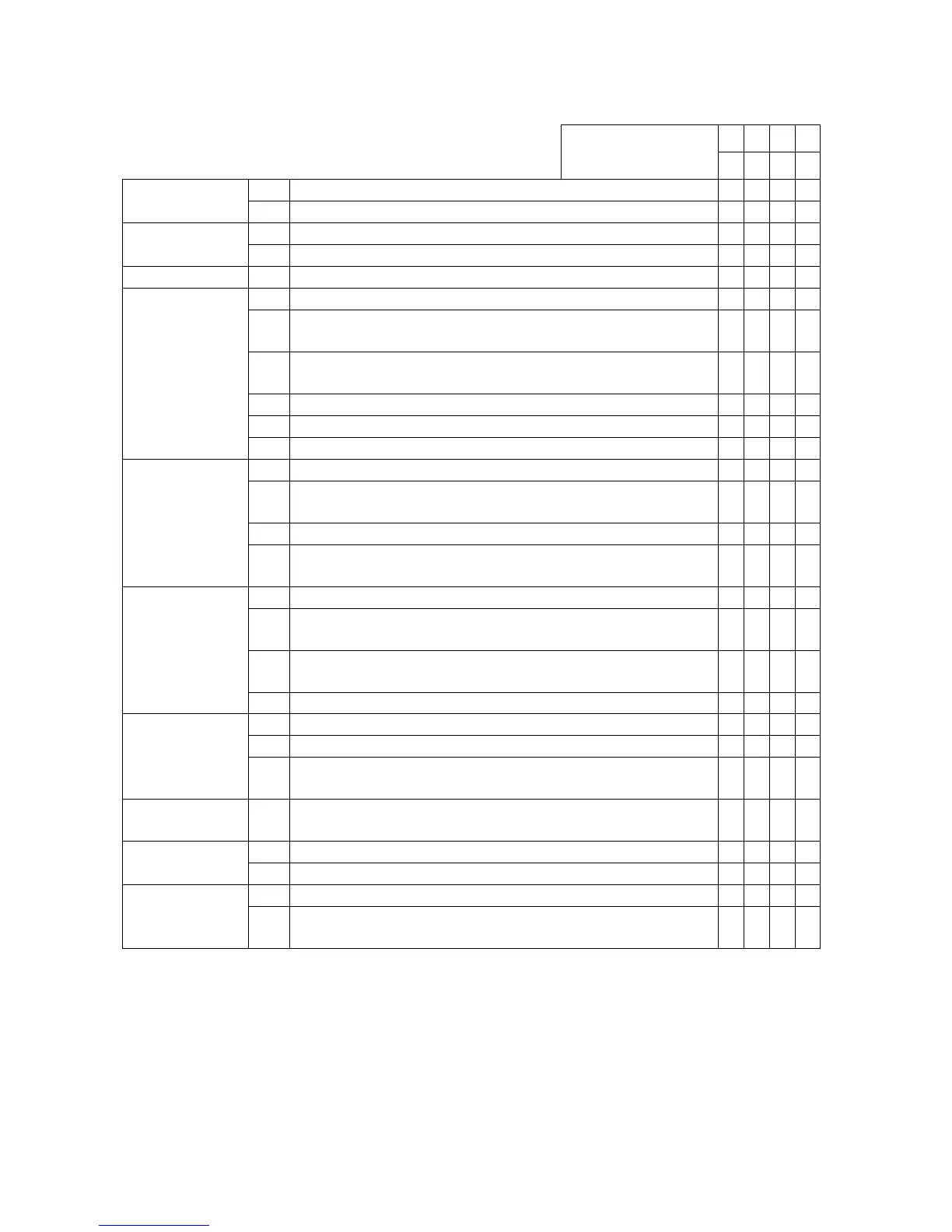

5 AMX-E Maintenance Checklist:

Maintenance intervals

Standard =

t

WA B C

Cold Store =

k

Chassis/

Design:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

Wheels: 2.1 Check wheels for wear and damage t

2.2 Check suspension and attachment t

Steering: 3.1 Check the steering play t

Hydraulic

System:

5.1 Test operation t

5.2 Check unions and connections for leaks and

and check damage

t

5.3 Make sure hydraulic unit is sealed, check for damage

and test attachment

t

5.4 Check oil level t

5.5 Replace hydraulic oil and filter cartridge t

5.6 Test pressure relief valves t

Electrical

System:

6.1 Test operation t

6.2 Check all cables are secure and check for damage t

6.3 Check fuse ratings t

6.4 Make sure switches are secure and are operating

correctly

t

Battery: 7.1 Check acid density, acid level and cell voltage t

7.2 Check terminals are securely attached, and apply

grease

t

7.3 Clean battery plug connections,

make sure they are tight

t

7.4 Check battery cables for damage, replace if necessary. t

Lift

mechanism:

8.1 Check operation, wear and setting t

8.2 Check the load wheels and plunger rods t

8.3 Check forks and fork carriage for wear and

damage

t

Lubrication: 9.1 Lubricate truck in accordance with Lubrication

Schedule.

t

General

Measurements:

10.1 Check electrical system for frame leakage t

10.3 Test lift and lowering speeds t

Demonstration: 11.1 Test run with rated load t

11.2 After completing maintenance, present the truck to

the supervisor

t

Loading...

Loading...