F 7

1003.GB

5.1 Operating Fluids

Handling Operating Fluids: Operating fluids must always be handled correctly and

in accordance with the manufacturer’s regulations.

F

Incorrect handling endangers health, life and the environment. Operating fluids may

only be stored in regulation containers. They may be inflammable therefore they

should not come into contact with hot components or flames.

When topping up operating fluids only use clean containers. Do not mix different

grade fluids. This regulation may only be disregarded if a mixture is specifically

prescribed in this instruction.

Do not spill fluids. Spilled fluids must be removed immediately with a suitable bonding

agent and the resultant mix must be disposed of in accordance with disposal

regulations.

Grease Guidelines

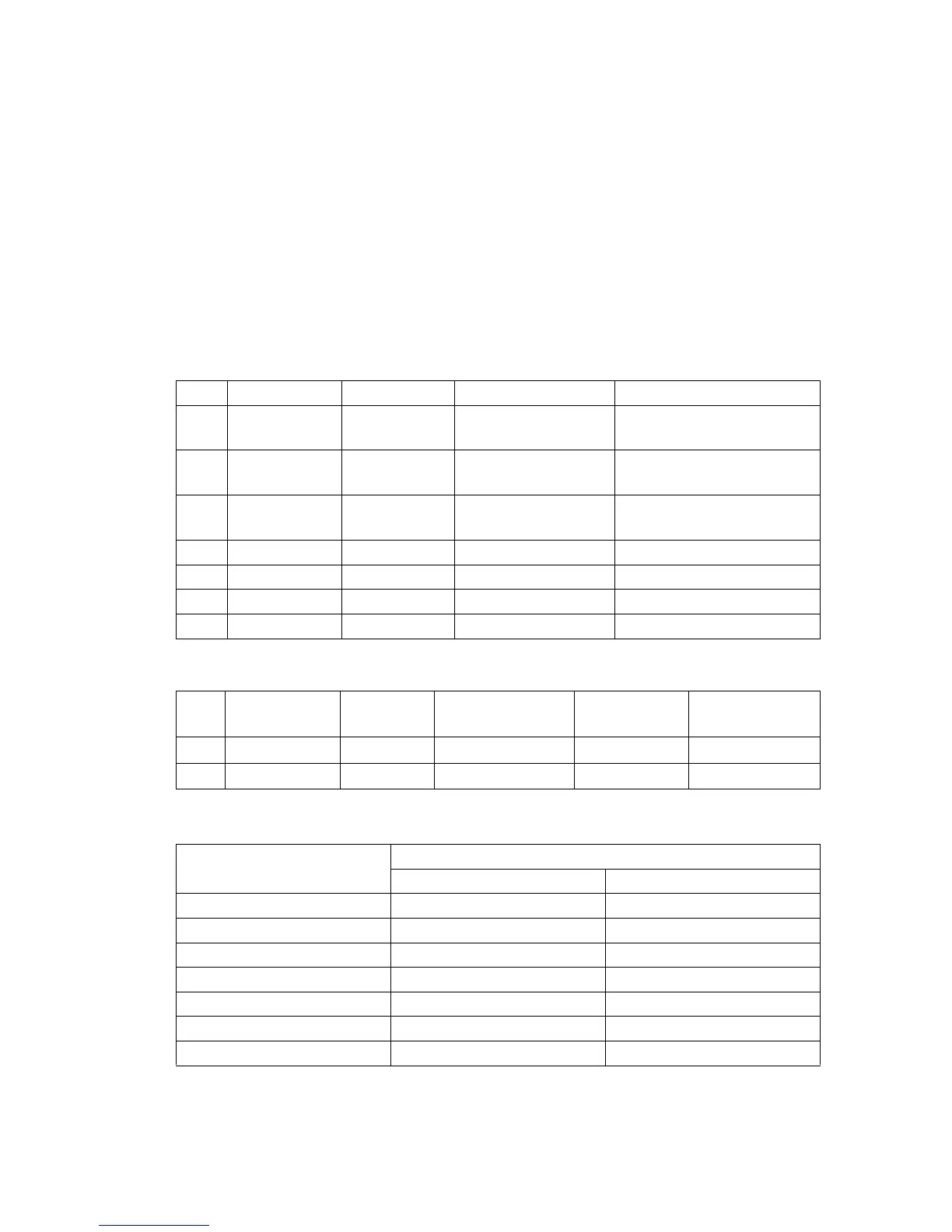

5.2 Tank Capacity ETM/V 214/216

Code Order No. Volume Description Application for

A 29 200 670 5.0 1 H-LP 46,

DIN 51524

Hydraulic Equipment

B 29 200 680 5.0 1 CLP 100,

DIN 51517

Gearbox

C 29 200 810 5.0 1 H-LP 10,

DIN 51524

Gearbox ,

Hydraulic Equipment

E 29 201 430 1.0 kg Grease, DIN 51825 Lubrication

F 29 200 100 1.0 kg Grease, TTF52 Lubrication

G 29 201 280 0.51 kg Chain Spray Chains

J 29 202 020 5 1 AeroShell Fluid 4 Hydraulic System

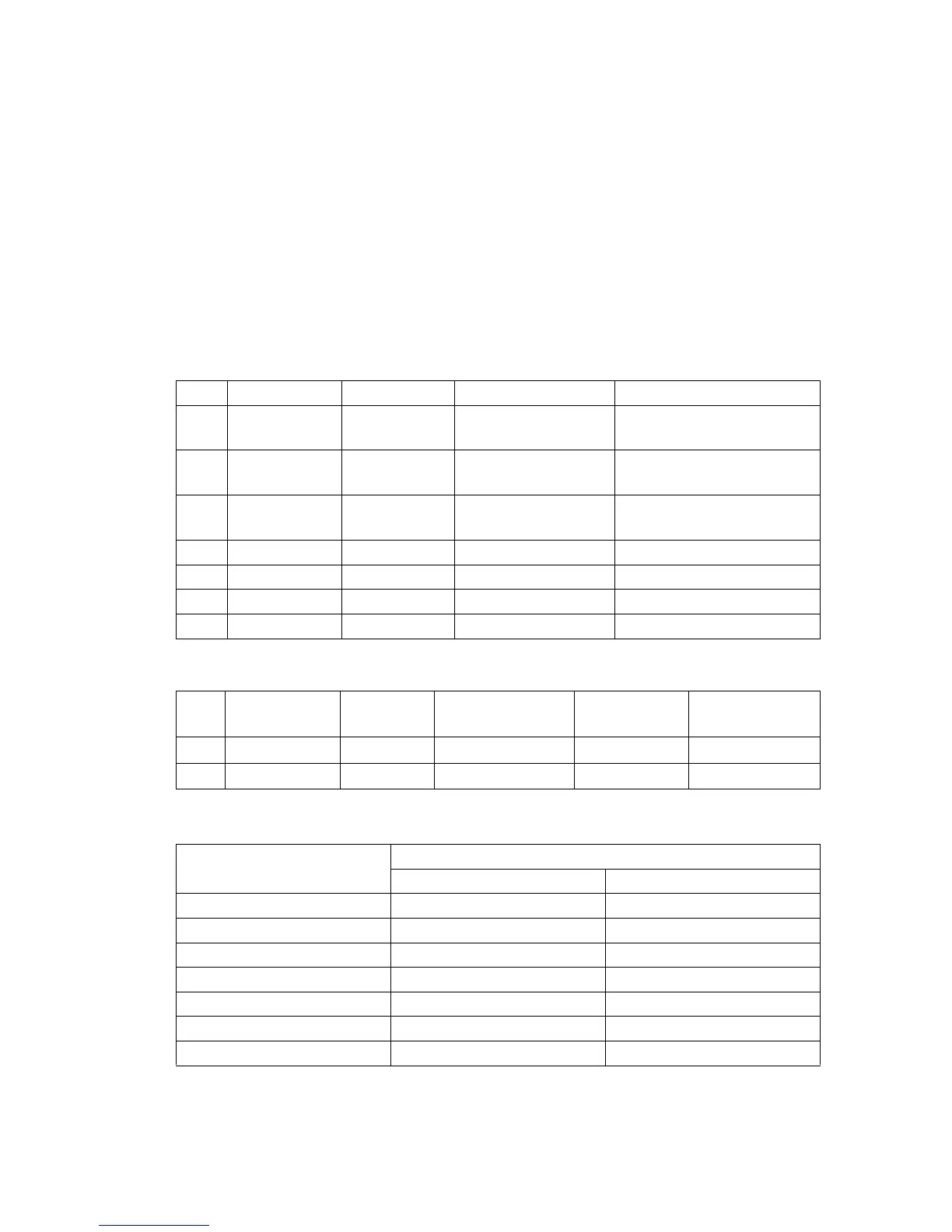

Code Type of

Saponification

Drop Point

° C

Walk penetration

at 25 °C

NLG1-Class Operating

temperature °C

E Lithium 185 265 - 295 2 -35 / +120

F -- -- 310 - 340 1 -52 / +100

Litre Lift Height (h

3

)

ZT DZ

approx. - up to 10250

approx. - up to 9620

approx. - up to 9020

approx. - up to 7400

approx. - up to 6200

approx. up to 4200 up to 4700

approx. - -

F 7

1003.GB

5.1 Operating Fluids

Handling Operating Fluids: Operating fluids must always be handled correctly and

in accordance with the manufacturer’s regulations.

F

Incorrect handling endangers health, life and the environment. Operating fluids may

only be stored in regulation containers. They may be inflammable therefore they

should not come into contact with hot components or flames.

When topping up operating fluids only use clean containers. Do not mix different

grade fluids. This regulation may only be disregarded if a mixture is specifically

prescribed in this instruction.

Do not spill fluids. Spilled fluids must be removed immediately with a suitable bonding

agent and the resultant mix must be disposed of in accordance with disposal

regulations.

Grease Guidelines

5.2 Tank Capacity ETM/V 214/216

Code Order No. Volume Description Application for

A 29 200 670 5.0 1 H-LP 46,

DIN 51524

Hydraulic Equipment

B 29 200 680 5.0 1 CLP 100,

DIN 51517

Gearbox

C 29 200 810 5.0 1 H-LP 10,

DIN 51524

Gearbox ,

Hydraulic Equipment

E 29 201 430 1.0 kg Grease, DIN 51825 Lubrication

F 29 200 100 1.0 kg Grease, TTF52 Lubrication

G 29 201 280 0.51 kg Chain Spray Chains

J 29 202 020 5 1 AeroShell Fluid 4 Hydraulic System

Code Type of

Saponification

Drop Point

° C

Walk penetration

at 25 °C

NLG1-Class Operating

temperature °C

E Lithium 185 265 - 295 2 -35 / +120

F -- -- 310 - 340 1 -52 / +100

Litre Lift Height (h

3

)

ZT DZ

approx. - up to 10250

approx. - up to 9620

approx. - up to 9020

approx. - up to 7400

approx. - up to 6200

approx. up to 4200 up to 4700

approx. - -

Loading...

Loading...