7.9 Load carrying

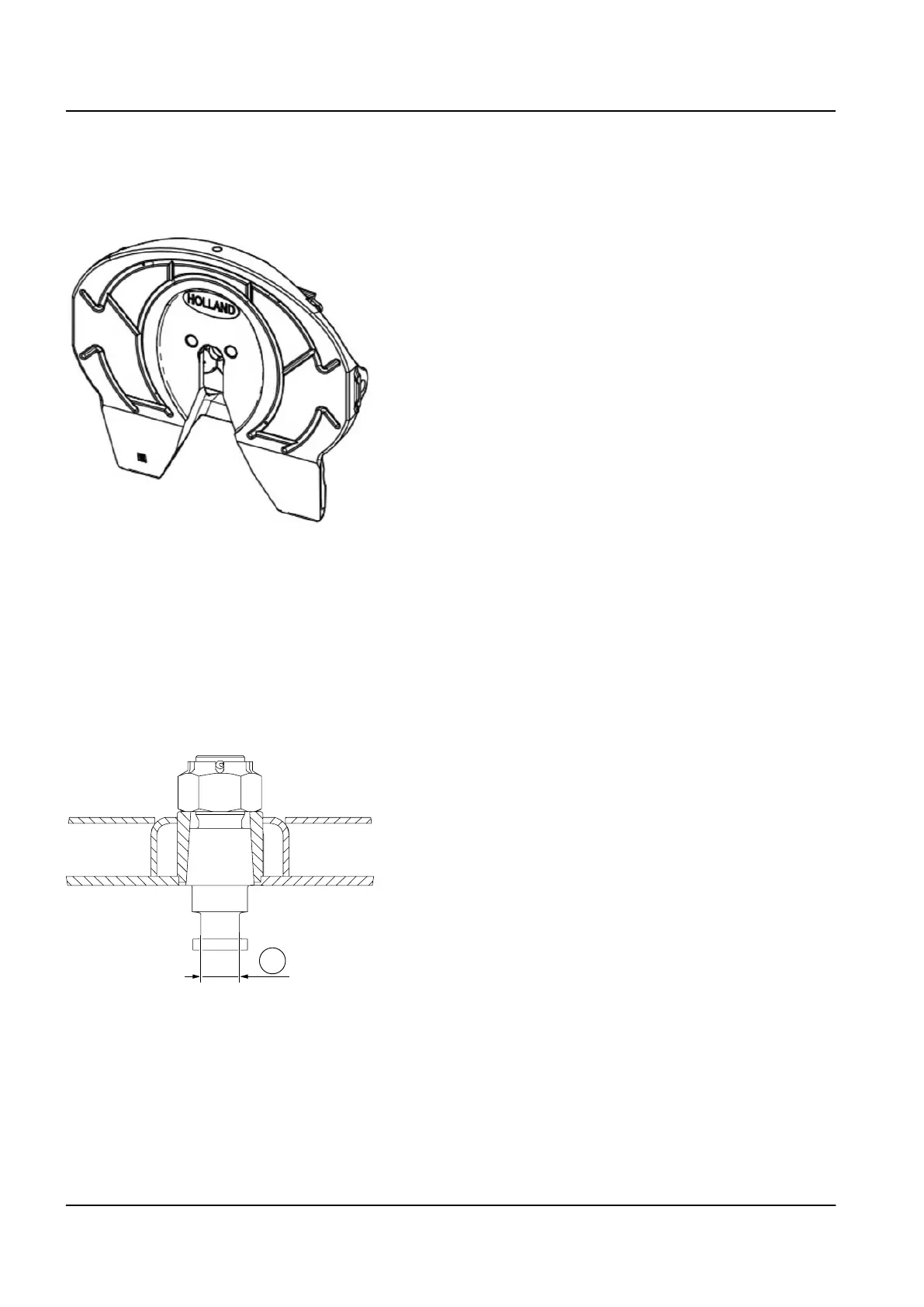

Maintenance of the fifth wheel

1 Remove the load handling device (gooseneck, trailer stand,

etc.), if equipped, from the fifth wheel.

2 Clean the fifth wheel with, e.g., a hot water washer.

3 Examine the fifth wheel surface and brackets for cracks and

fractures.

If any cracks are detected or if the surface is worn to the bot‐

tom of the lubrication grooves, replace the fifth wheel.

Lubrication

NOTE

When using the same trailer repeatedly, lubrication must be per‐

formed every 100 hours of operation.

1 Detach the trailer from the fifth wheel.

2 Lubricate the components with the grease nipples using a

greasegun.

3 Use a brush to lubricate parts without grease nipples.

Lubrication points

•

the joint surfaces between the fifth wheel and the lift boom

•

the top surface, jaws, and slide of the fifth wheel

•

the joints in the locking mechanism of the hitch

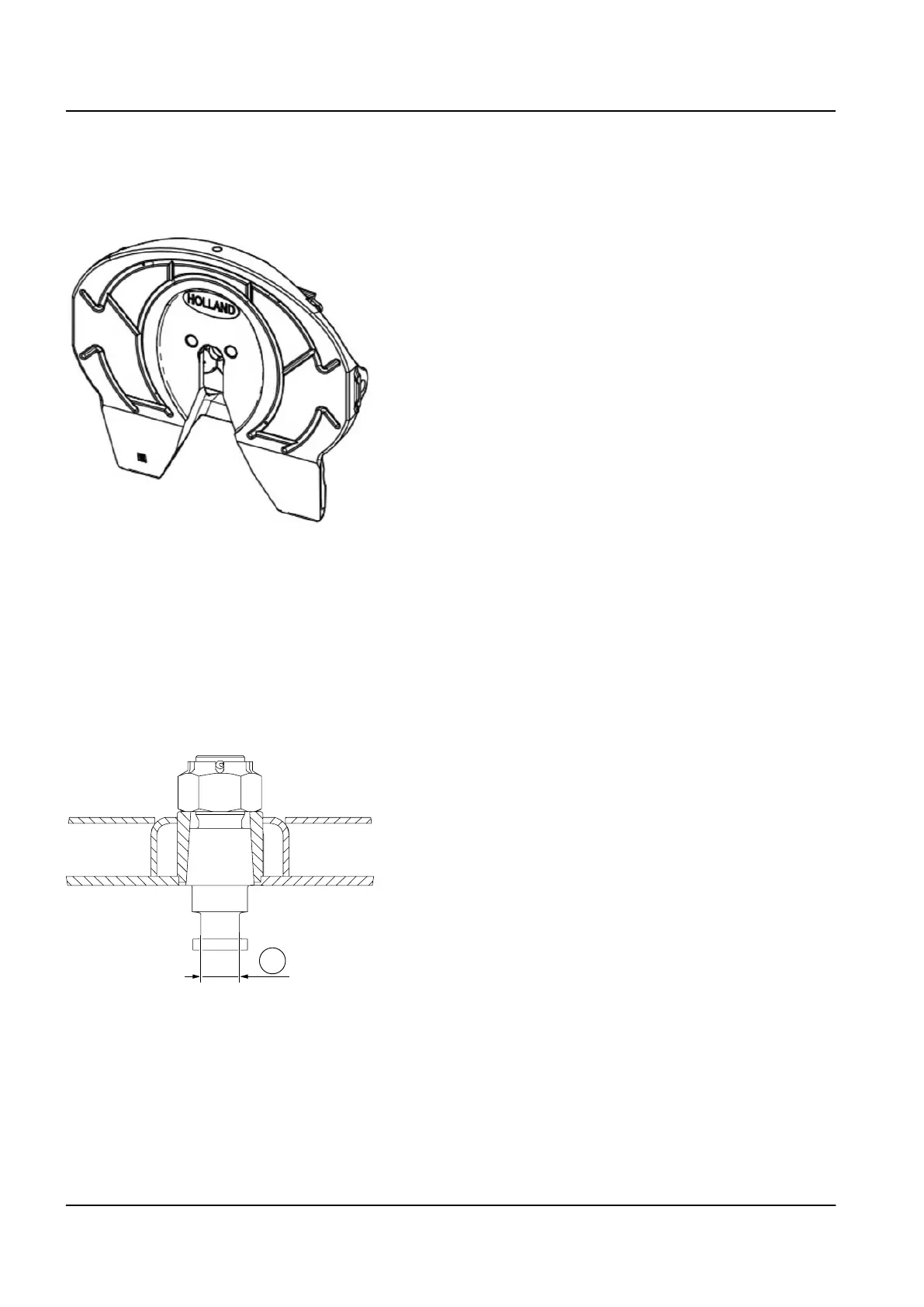

Examine of the kingpin

1 Examine the wear of the kingpin locking components and

operation of the locking mechanism. Lubricate the surface of

the fifth wheel and the joints thoroughly.

2 Test the locking mechanism with a steel plate that has a wel‐

ded kingpin.

The engaged kingpin must hold tightly without any clearance.

However, the kingpin must also rotate lightly. At that point, the

kingpin locking indicator light (H8) should be lit.

3 Measure the diameter (A) of the kingpin. The diameter must

be at least 48.0mm with a 2" pin and at least 86.0mm with a

3.5" pin.

Worn components must be replaced immediately.

The locking jaws and slide must always be replaced as a pair.

Fifth wheel Holland FW3500

4 7 Load handling – 7.9 Load carrying

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...