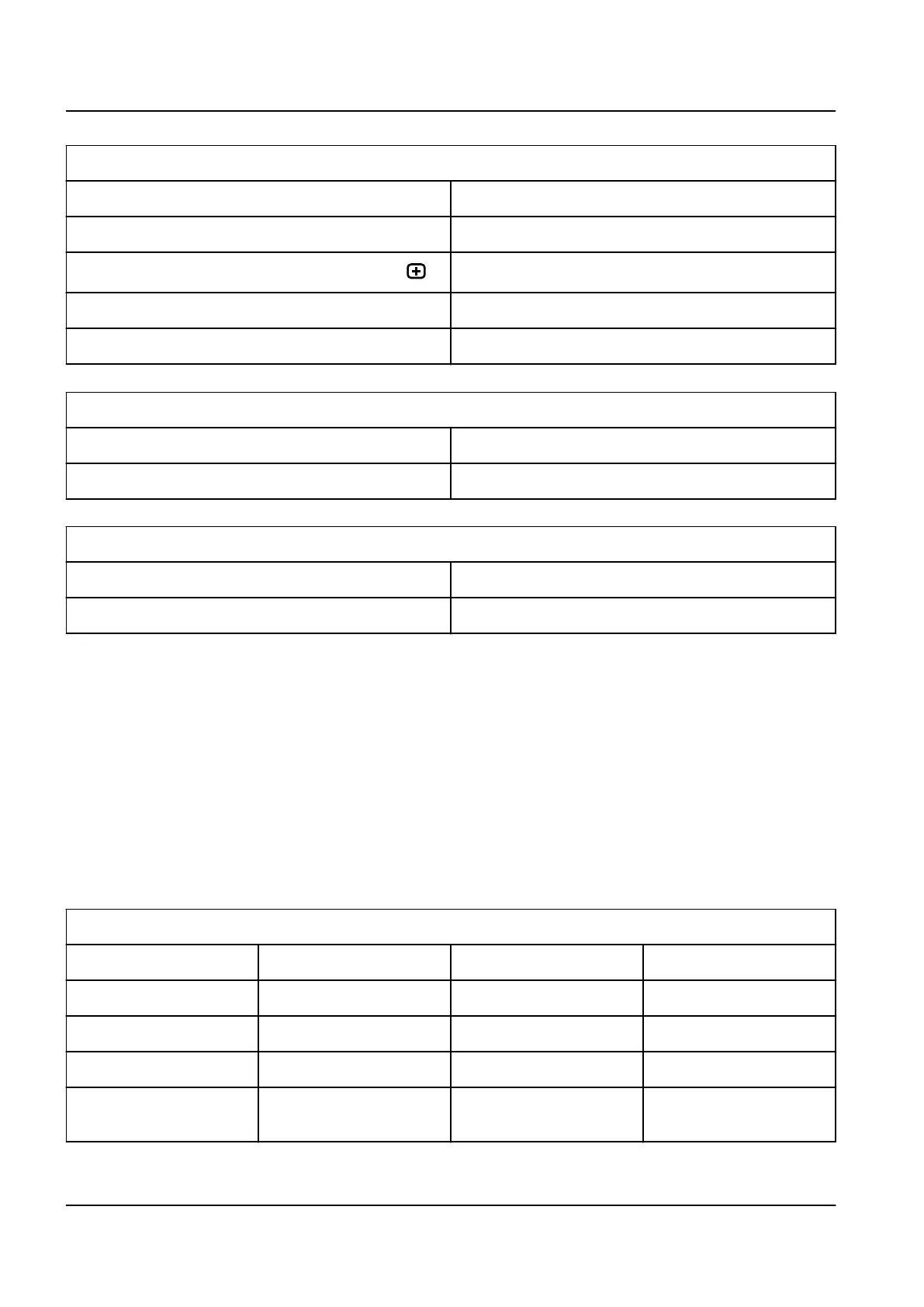

6 Suspension and wheels

Maintenance item Reference

Tighten the axle mounting screws see:

6.2 Suspension

Examine the operation of the rear axle air suspension

see:

6.2 Suspension

Tighten the wheel mounting nuts see:

6.3 Tyres and rims

Examine the tyre pressure see:

6.3 Tyres and rims

9 Frame, cab and accessories

Maintenance item Reference

Lubricate the points specified in the lubrication schedule see:

Lubrication

10 Common hydraulics

Maintenance item Reference

Replace the filter element of the return filter see:

10.6 Temperature control, cleaning and hydraulic oil

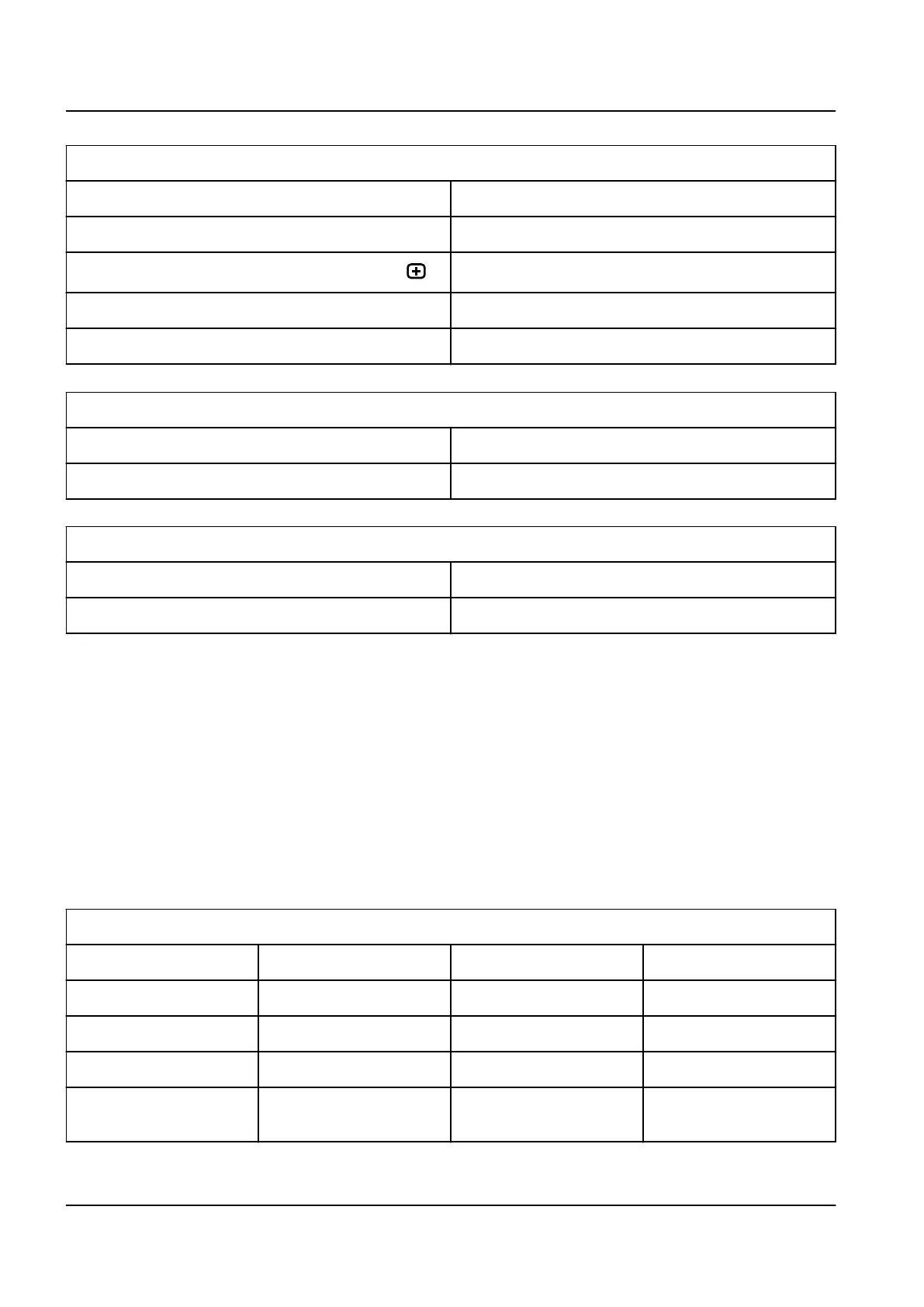

Scheduled maintenance

General

The 500-hour maintenance is to be performed at 500, 1,000, 1,500

hours, and so on.

The 1,000-hour maintenance is to be performed at 1,000, 2,000,

3,000 hours, and so on.

The 2,000-hour maintenance is to be performed at 2,000, 4,000,

6,000 hours, and so on.

Lubrication must also be performed during scheduled maintenance.

Maintenance table

1 Engine

Maintenance item Service interval (hours) Note Reference

Examine the radiator 250 see:

1.7 Cooling system

Examine the radiator hoses 250 see:

1.7 Cooling system

Examine the cooling fan 250 see:

1.7 Cooling system

Examine the air intake

piping

250 see:

1.6 Intake and exhaust

system

6 C Preventive maintenance – Maintenance programme

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...